Method for preparing cellulose based dye waste water purification material with waste newspaper

A technology for dye wastewater and purification materials, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc. problems, to achieve the effect of being conducive to environmental protection, simplifying the treatment process, and achieving ideal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

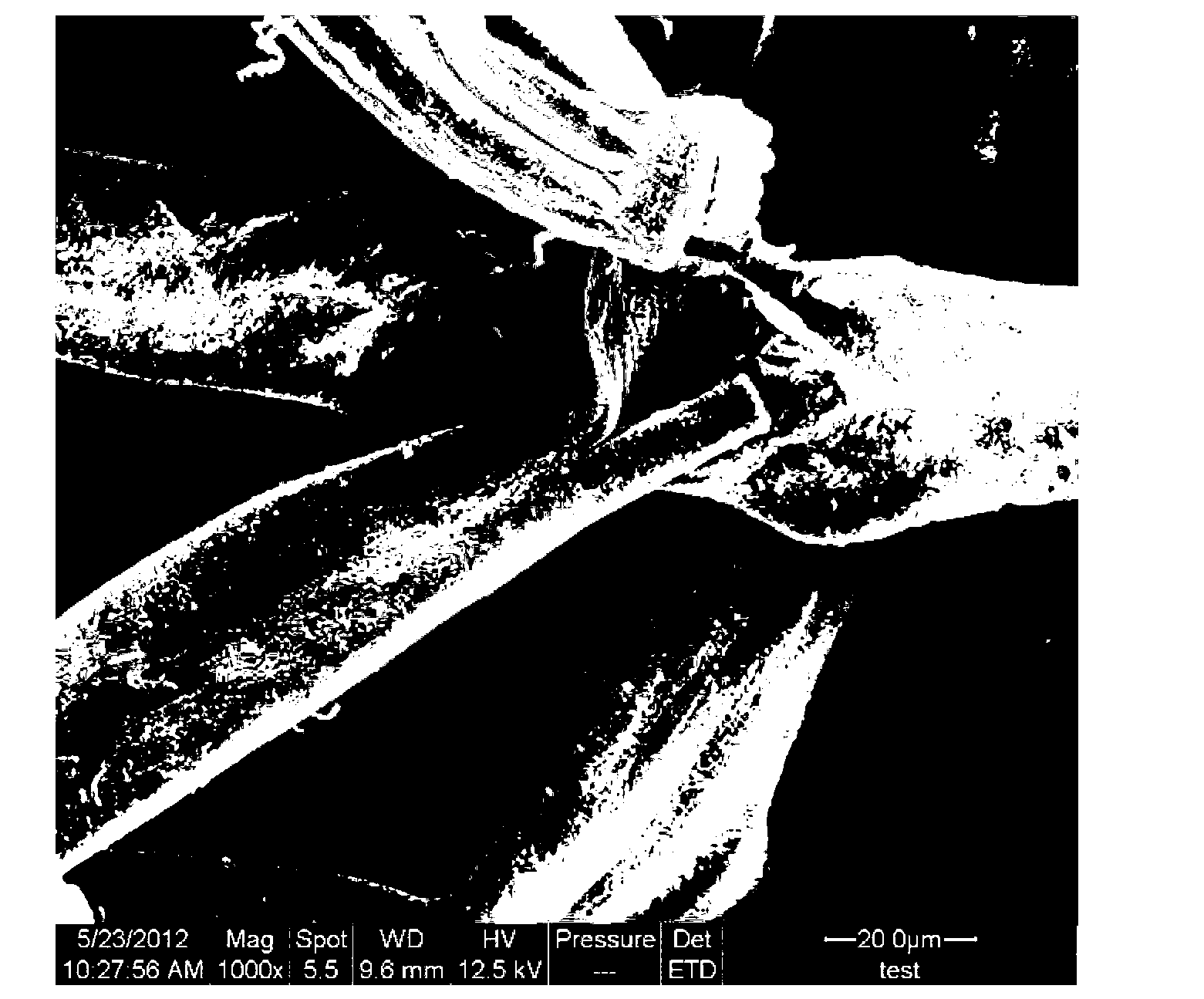

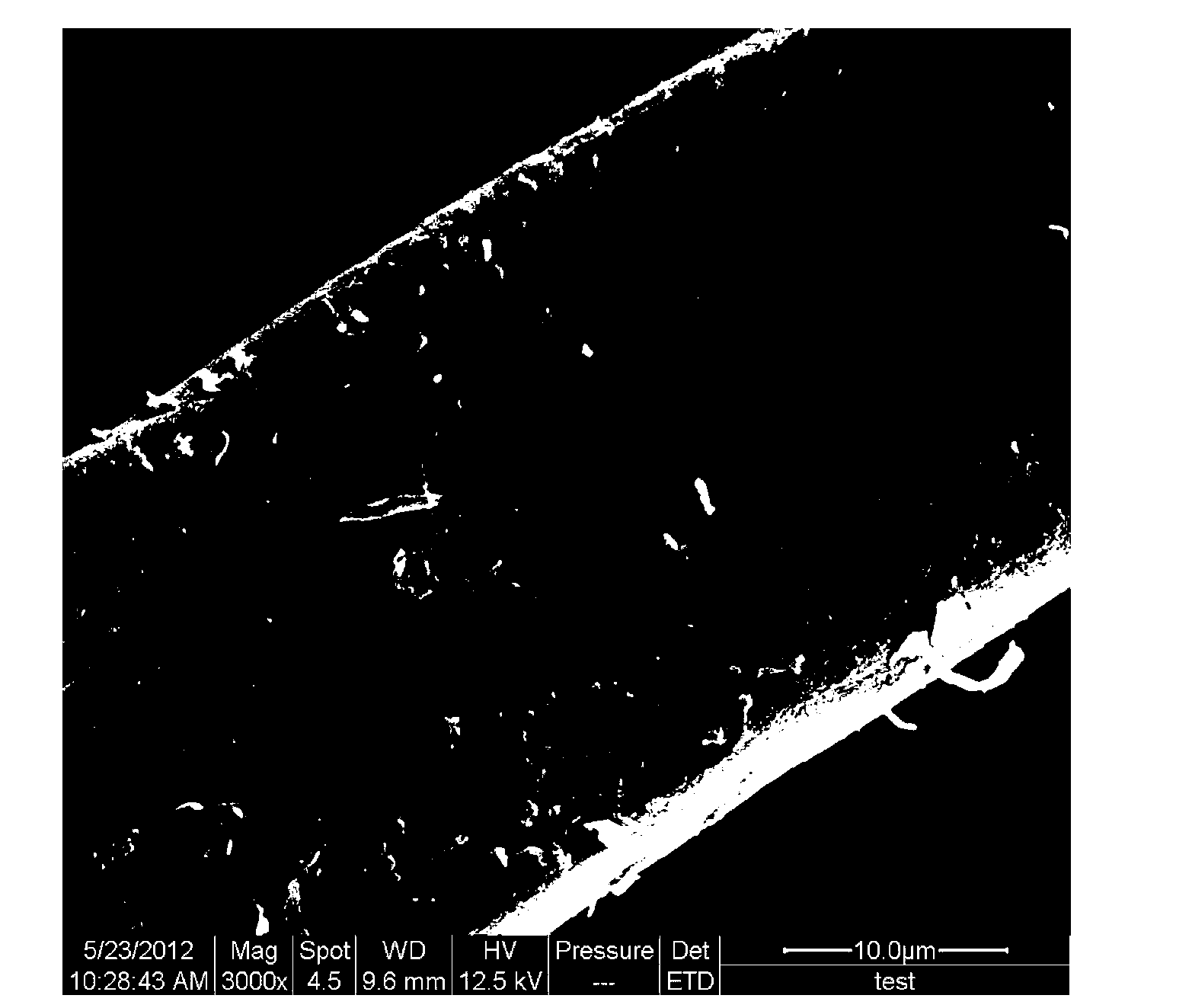

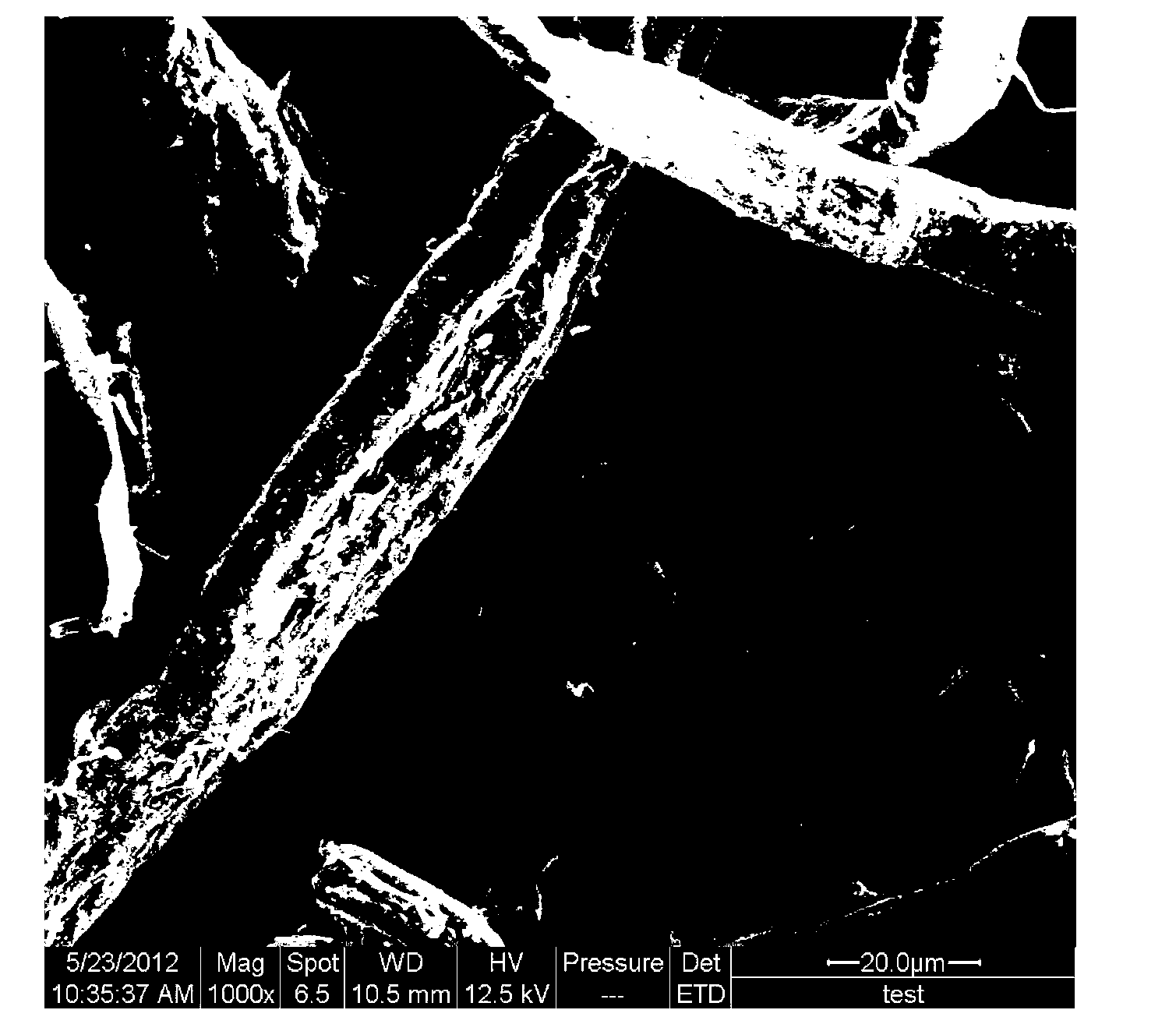

Image

Examples

specific Embodiment approach 1

[0022] Specific implementation mode 1: The method for preparing cellulose-based dye wastewater purification materials by using waste newspapers in this embodiment is implemented in the following steps:

[0023] 1. Put 150g of waste newspaper and 3~6g of Na 2 Si 3 ·9H 2 O, 1.5~4.5g of H 2 O 2 , 1.5~4.5g of NaOH and 3~6g of surfactant are mixed, and then stirred at 65℃ for 1h to obtain the deinked cellulose, which is then washed with distilled water for 6-8 times, and then dried by blowing Dry in a box at 100°C to obtain waste newspaper fibers, which are then crushed and screened out to 80-120 mesh waste newspaper fibers;

[0024] 2. Take 5g of 80-120 mesh waste newspaper fiber, add 125mL of 20% NaOH solution in a 250mL three-necked flask, stir at room temperature for 1h, filter out 62.5mL of NaOH solution, and then add 40mL of epichlorohydrin. Stir at a speed of 180r / min at 65°C for 6 hours, filter the water out of the obtained cellulose with a 400-mesh gauze, and wash it with anhyd...

specific Embodiment approach 2

[0031] Specific embodiment two: This embodiment is different from specific embodiment one in that in step one, 150g of waste newspaper and 4g of Na 2 Si 3 ·9H 2 O, 3g of H 2 O 2 , 3g of NaOH and 4g of surfactant are mixed. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: this embodiment is different from specific embodiment one or two in that in step one, 100 mesh waste newspaper fibers are sieved. Other steps and parameters are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com