A kind of low-shrinkage nano-composite resin for dental restoration and preparation method thereof

A low-shrinkage, nano-composite technology, applied in the field of preparation of dental restoration materials, can solve the problems of polishing retention, poor wear resistance and durability, difficulty in large-scale production, and biological safety hazards, etc., to improve polishing retention Durability and wear resistance, reduction of polymerization shrinkage, comprehensive performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

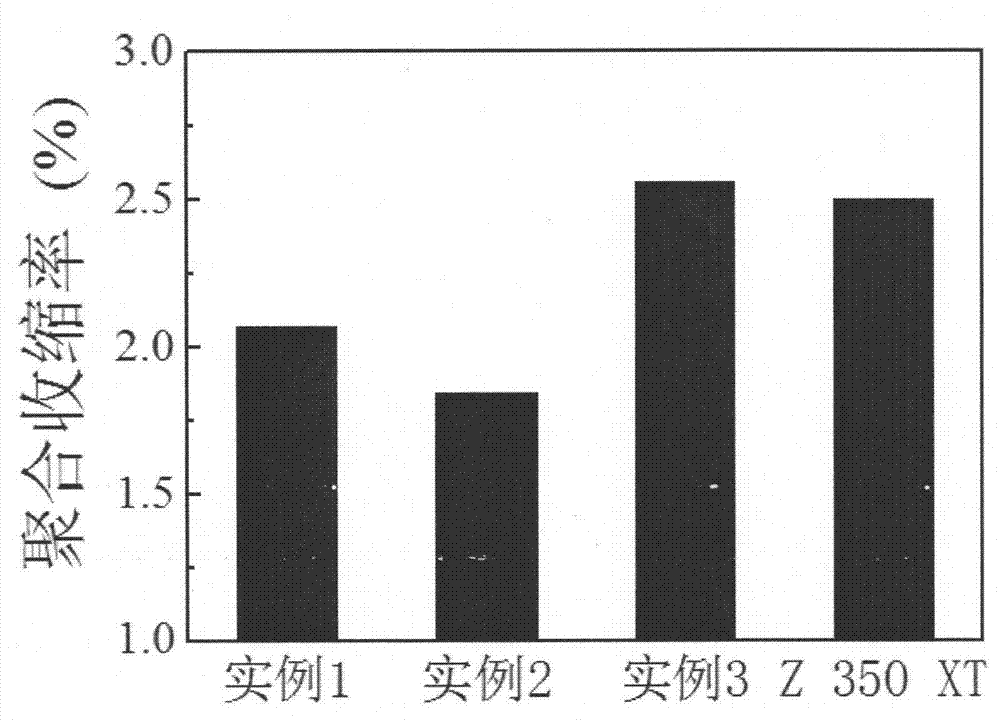

Examples

Embodiment 1

[0034] 1. The raw materials and proportioning ratio are shown in Table 1

[0035] Table 1

[0036] components

Mass percentage (wt%)

UDMA

12.00

TEGDMA

16.00

BP

0.40

DMAEMA

1.60

Silanized Nano Silica

34.00

Silanized Micron Silica

34.00

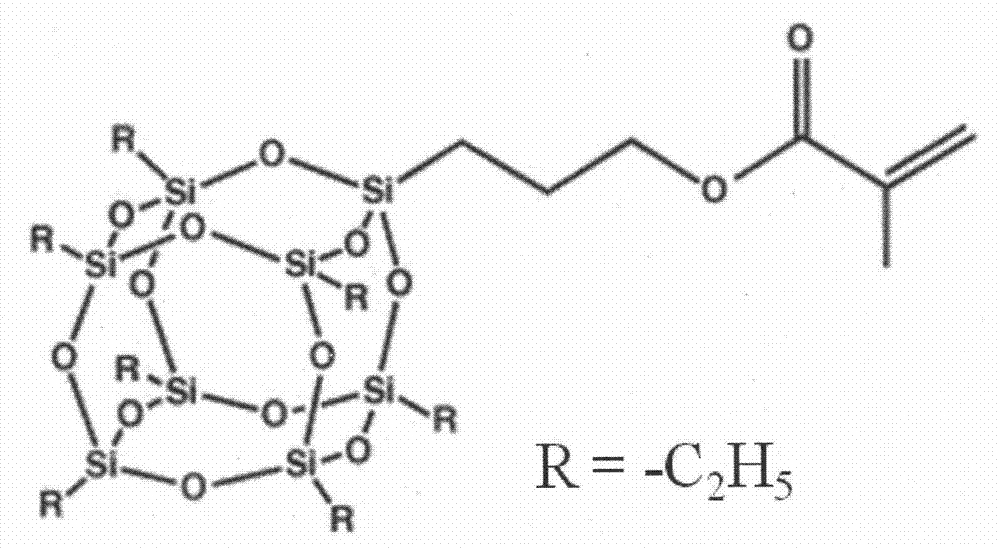

Heptaethyl-methacrylate POSS

2.00

[0037] 2. Preparation method

[0038] (1) Preparation of silanized inorganic filler

[0039] 5.0g inorganic filler (including nano-silica and micro-silica, the weight ratio is 1:1), 0.2g catalyst n-propylamine and 0.8g double bond-containing silane coupling agent (γ-methacryloyloxy propyltrimethoxysilane) was added to 100mL cyclohexane solvent, reacted at room temperature for 40min, then stirred at 60°C for 40min, after removing the solvent, dried in a vacuum oven at 60°C for 24h to obtain the inorganic filler with silanized surface .

[0040] (2) Preparation of photocurable composite resin

[0041] Mix UDMA, TEGD...

Embodiment 2

[0045] 1. The raw materials and proportioning ratio are shown in Table 2

[0046] Table 2

[0047] components

Mass fraction (wt%)

Bis-GMA

14.50

TEGDMA

14.50

CQ

0.25

4-EDMAB

0.75

Silanized Nano Silica

45.00

Silanized silica clusters

20.00

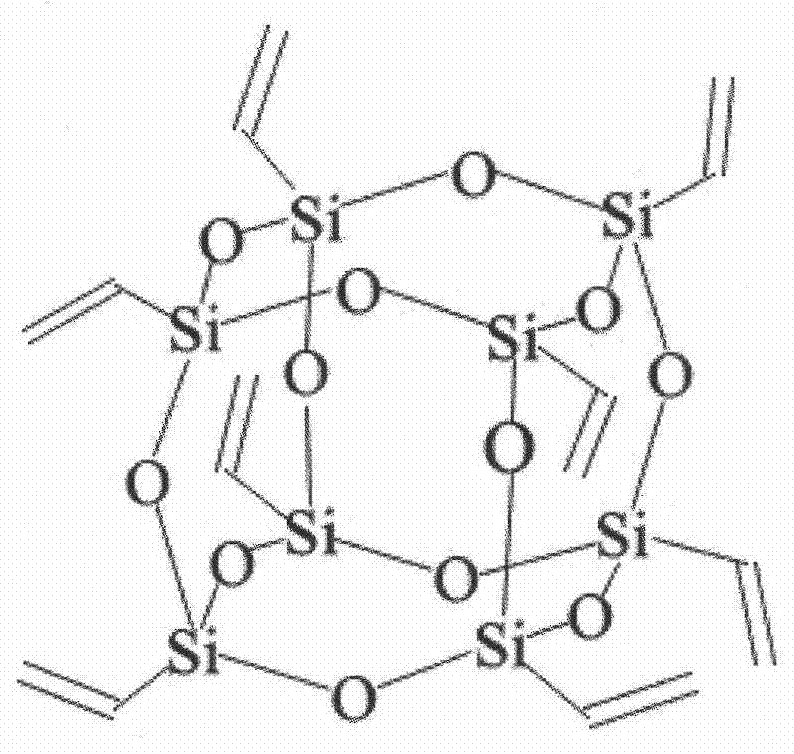

Octavinyl POSS

5.00

[0048] (1) Preparation of silanized inorganic filler

[0049] 5.0g of inorganic filler (including nano-silica and silica clusters, the weight ratio is 45:20), 0.2g of catalyst n-propylamine and 0.8g of double bond-containing silane coupling agent (γ-methacryloyl Oxypropyltrimethoxysilane) was added to 100mL cyclohexane solvent, reacted at room temperature for 40min, then stirred at 60°C for 40min, after removing the solvent, dried in a vacuum oven at 60°C for 24h to obtain the surface silanized inorganic filler.

[0050] (2) Specific preparation steps of light-cured composite resin

[0051] According to the ratio in the fo...

Embodiment 3

[0055] 1. The raw materials and proportioning ratio are shown in Table 3

[0056] table 3

[0057] components

Mass fraction (wt%)

UDMA

14.00

TEGDMA

10.00

PPD

0.20

DMAEMA

0.80

Silanized Nano Silica

45.00

Silanized silica clusters

15.00

Octavinyl POSS

15.00

[0058] (1) Preparation of silanized inorganic filler

[0059] 5.0g inorganic filler (including nano-silica and silica clusters, the weight ratio is 3:1), 0.2g catalyst n-propylamine and 0.8g double bond-containing silane coupling agent (γ-methacryloyl Oxypropyltrimethoxysilane) was added to 100mL cyclohexane solvent, reacted at room temperature for 40min, then stirred at 60°C for 40min, after removing the solvent, dried in a vacuum oven at 60°C for 24h to obtain the surface silanized inorganic filler.

[0060] (2) Specific preparation steps of light-cured composite resin

[0061] According to the ratio in the formula in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com