Improved junction box for circulating preheater of single-cavity permanent magnet rotor pump

A permanent magnet rotor and junction box technology, applied in the field of junction boxes, can solve the problems of not meeting the special requirements of electrical safety, reduce the IP protection level, reliability and electrical safety of the preheater, and improve the IP protection level. , the effect of easy assembly and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

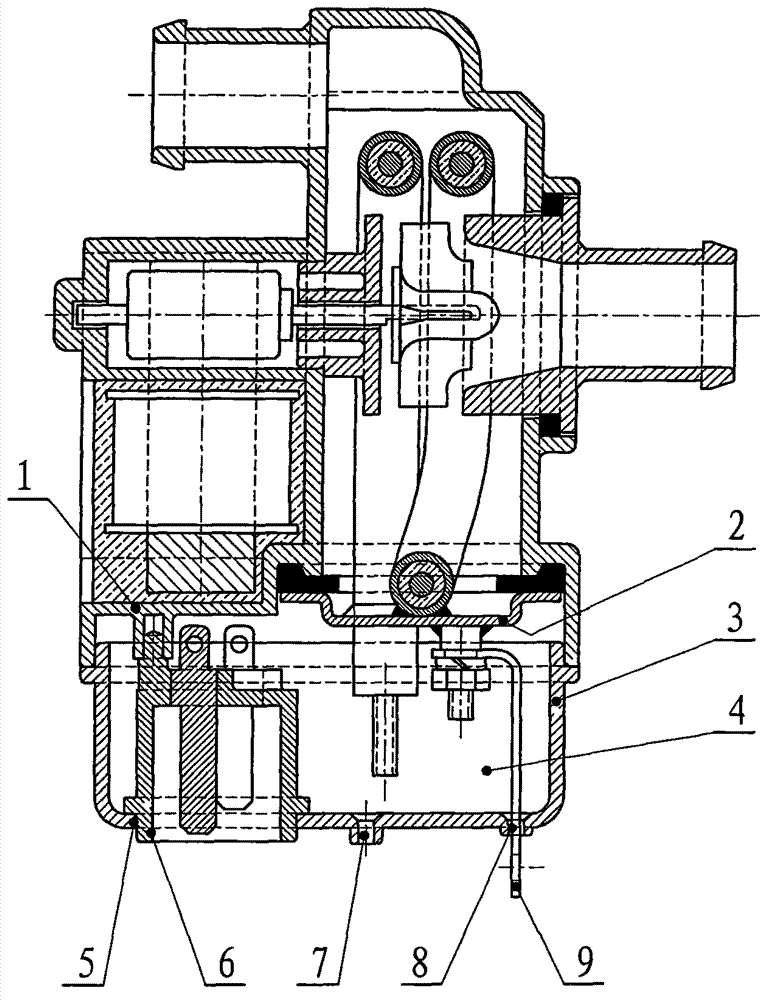

[0012] The specific implementation and examples of the present invention will be described below in conjunction with the accompanying drawings.

[0013] It can be seen from Figure 1 that the cavity main body (1) is connected with the junction box cover (3) below to form the protective shell of the junction box (4), the input socket (6) connects the power supply to the junction box (4), and the junction box cover (3) The junction with the cavity main body (1) is fully embedded in the cavity main body (1), and the bottom of the junction box cover (4) has an input socket hole (5), a drain hole (7) with a raised edge and a raised edge the terminal hole (8), the input socket (6) passes through the input socket hole (5) and the socket faces downward, the PE protective earth terminal (9) passes through the terminal hole (8) and protrudes from the junction box cover (3) On the side, such a structure can simply but significantly improve the waterproof performance to improve the IP prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com