Support frame

A support frame and support column technology, which is applied in the field of support frames, can solve the problems of the supported object rollover and support instability of the support frame, and achieve the effects of not being easy to rollover, conducive to precise operation, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

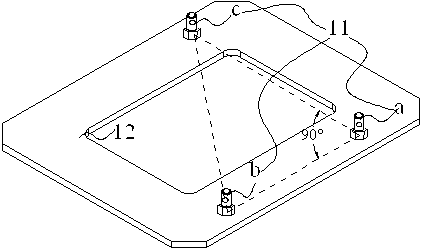

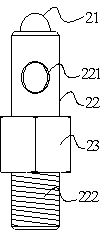

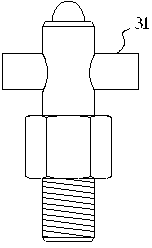

[0043] a support such as figure 1 As shown, it includes three support columns 11 and a substrate 12 for fixing the support columns; the support columns 11 are distributed on the abutment 12, and the positions of the three support columns form a right triangle; figure 2 Shown is a schematic diagram of the structure of the support column 11, which is inlaid by a spherical head 21 and a bar bar 22. A through hole 221 for adjustment is provided on the bar bar 22, and a threaded structure 222 is provided at the lower end of the bar bar 22. , the other bar area is provided with a nut 23 for loosening the support column; image 3 Shown is a structural schematic diagram of inserting the adjustment bar 31 in the support column; in order to improve the stability and practicability of the support frame, the support column 11 is made of wear-resistant stainless steel, and the abutment 12 for fixing the support column is made of light aluminum Made of alloy material.

[0044]

Embodiment 2

[0046] A support frame, including a support column and an abutment for fixing the support column, three support columns are distributed near the periphery of the abutment; the structure of the support column is the same as that of Embodiment 1, which is composed of a spherical structure and a cylindrical structure, and The materials are all made of hard wear-resistant stainless steel, and the hard abutment is made of light aluminum; there are threaded holes on the abutment corresponding to the threaded structure of the support column, and the support column is screwed and fixed on the support column through the thread structure. on the abutment. The points where the three support columns are located form the three vertices of the triangle, and the formed triangle is an isosceles acute triangle. Insert the adjustment bar into the support column.

[0047]

Embodiment 3

[0049] A support frame, including a support column and an abutment for fixing the support column, three support columns are distributed near the periphery of the abutment; other parts are similar to Embodiment 1, but the structure of the support column is composed of an elliptical structure and a cylinder Structural composition, the elliptical curved surface structure is the support part, and its material is made of hard wear-resistant stainless steel, the support column is fixed on the hard abutment by screwing, and the hard abutment is made of light aluminum material Obtained; the points where the three support columns are located form the three vertices of the triangle, and the formed triangle is a non-isosceles acute triangle, and the adjustment bar is inserted into the support columns.

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com