Ultrahigh-pressure fire-fighting hose

A fire hose and ultra-high pressure technology, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve problems such as poor pressure resistance, shorten fire extinguishing time, reduce personal and property losses, and reduce labor Strength, prolonging service life, and improving the effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

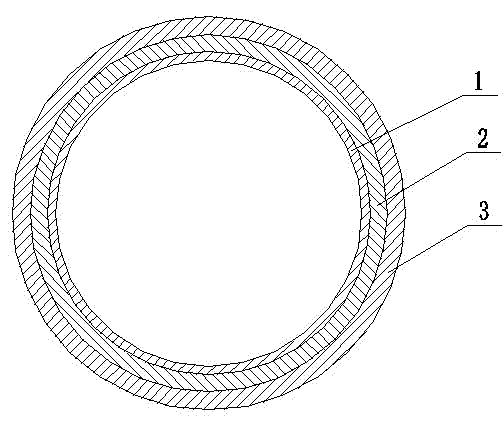

[0007] Such as figure 1 As shown, the inner layer of the present invention is a polyurethane rubber hose 1, the middle layer is a woven twill braided tube 2 with a 2 up and 1 down structure, and the outer layer is a woven twill braided tube 3 with a 2 up and 2 down structure.

[0008] The braided tubes 2 and 3 of the middle layer and the outer layer are all made of high-strength polyester industrial yarn, and the inner layer is made of polyurethane hose material as a lining. The two braided layers and the polyurethane hose are bonded together by high-temperature thermal bonding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com