Double-wall crack formwork support

A supporter and slotted technology, which is applied in the field of double-wall slotted formwork supporters, can solve the problems of inconvenient installation and removal, easy compression and deformation, and small adjustment range, and achieves low single-use cost, no deformation of support, and large adjustment range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

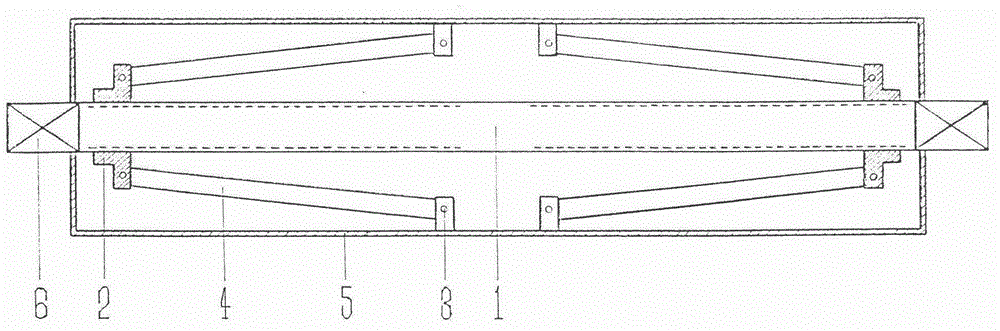

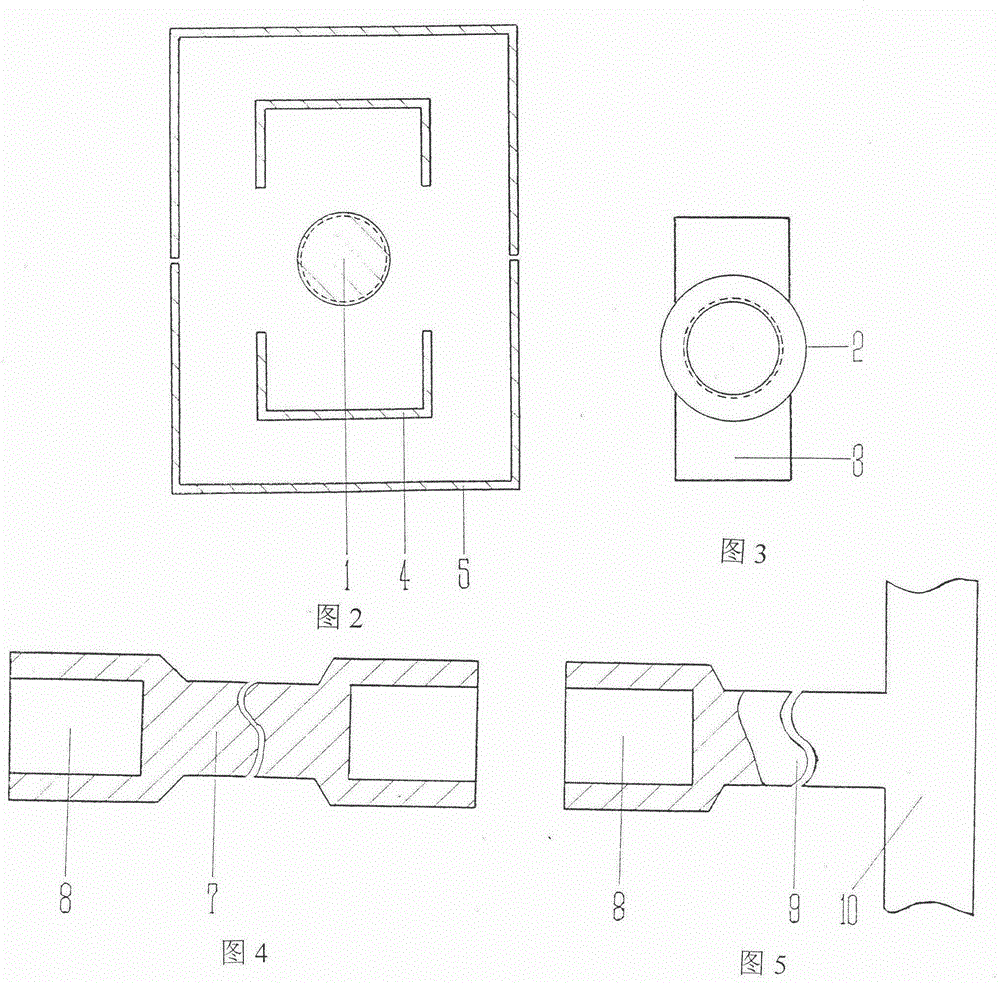

[0014] Such as figure 1 , figure 2 , image 3 As shown, the double-wall sandwich formwork supporter of the present invention is composed of positive and negative lead screws 1, nut blocks 2, movable joints 3, support rods 4 and support plates 5. Both ends of the positive and negative lead screw 1 are designed with a wrench 6, and the corresponding two sides of the nut block 2 are provided with movable joints 3 and matched with the positive and negative lead screw 1 as a complete set. The support plate 5 is a channel steel box with two ends blocked by steel stamping, and the support rod 4 is combined with the movable joint 3 in the support plate 5 grooves through the fixed holes at both ends to form a long rectangular whole.

[0015] Such as Figure 4 As shown, the tandem rod 7 is an independent accessory with inner pulleys 8 corresponding to the pulleys 6 at both ends of the positive and negative lead screw 1.

[0016] Such as Figure 5 As shown, the wrench lever 9 is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com