A sealing device for a calender and a transition roller table in a calendered glass production line

A glass production line and sealing device technology, which is applied in glass forming, glass rolling, glass manufacturing equipment, etc., can solve the problems of heat energy loss, lower melting temperature of melting furnace, and failure to achieve rational utilization of resources, so as to save energy and reduce The effect of heat loss and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

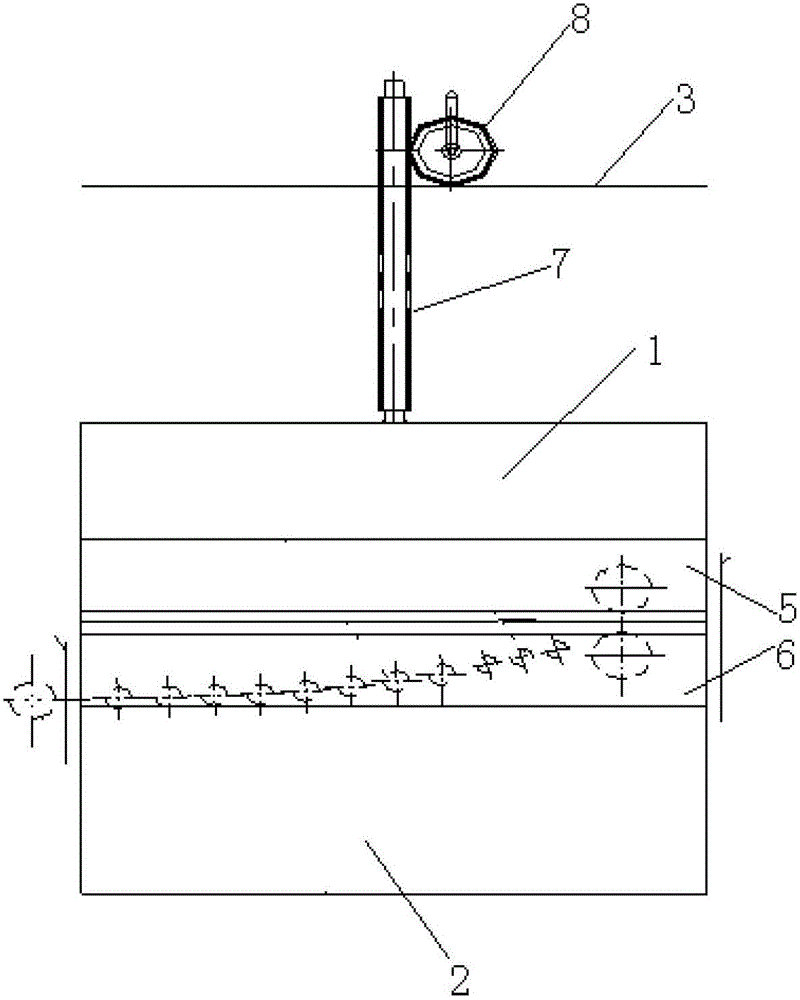

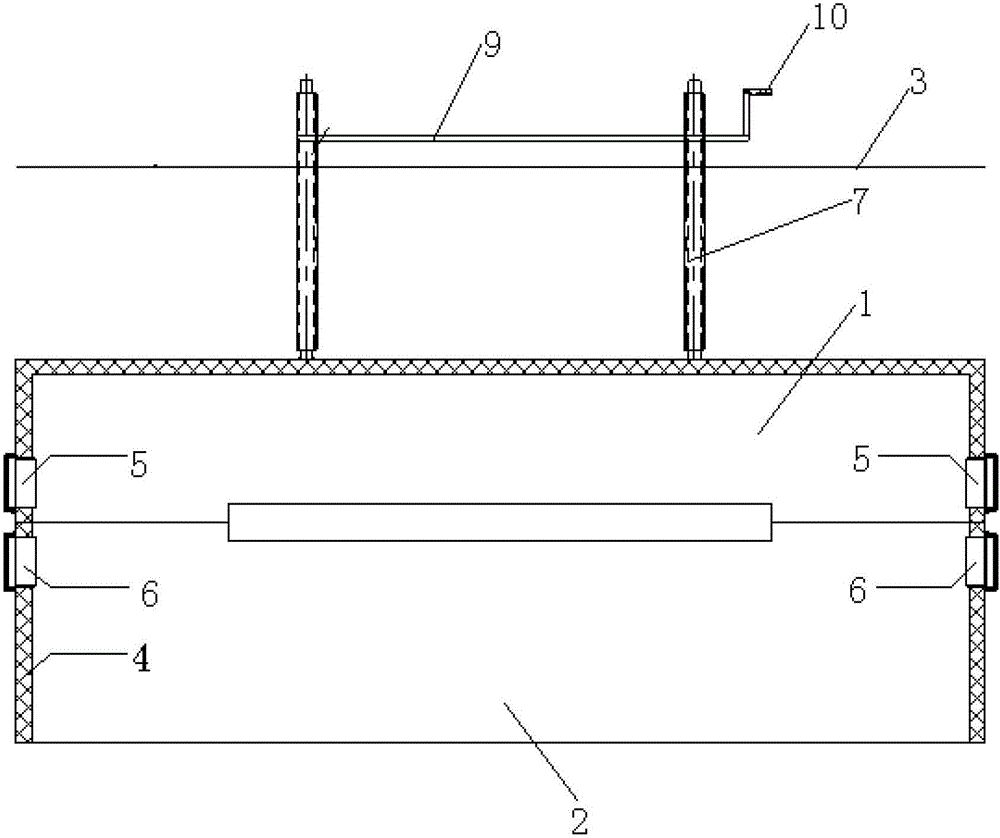

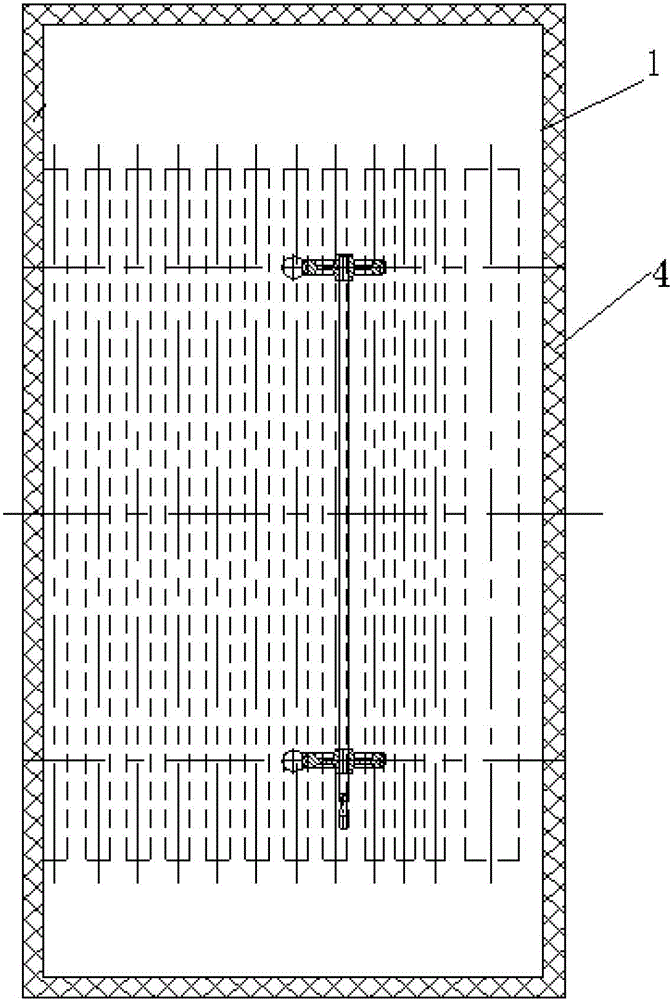

[0020] Referring to the accompanying drawings, a sealing device for a calender and a transition roller table in a rolling glass production line includes a sealing device arranged between a melting furnace and an annealing kiln, and the sealing device includes an upper sealing body, a lower Sealing bodies 1 and 2, the upper sealing body 1 is arranged on the top of the calender and the transition roller table, the lower sealing body 2 is arranged on the lower part of the calender and the transition roller table, and the front parts of the upper sealing body 1 and the lower sealing body 2 are respectively connected with The connection and rear part of the melting furnace are respectively connected with the annealing kiln, and there are conveying holes or grooves on the connection mating surface respectively. The body 1 is fixed on the ground track between the calender and the transition roll.

[0021] The upper sealing body 1 and the lower sealing body 2 are all box structures wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com