Wear detection device for elevator driving rope sheave and detection method

A detection device and detection method technology, applied in the direction of measuring devices, transportation and packaging, instruments, etc., can solve the problems of not considering the slippage of the elevator driving rope sheave and the low accuracy of wear detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

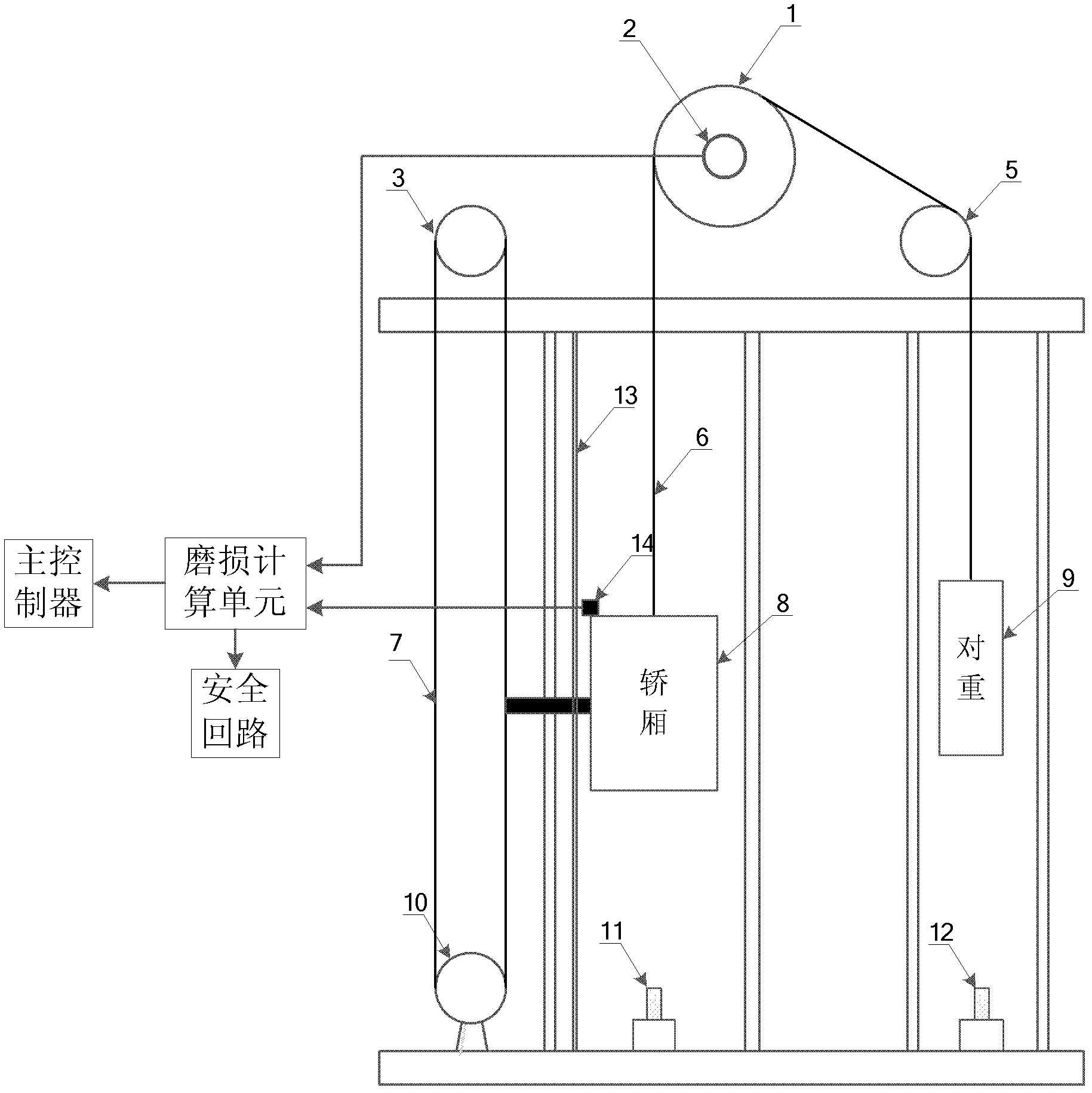

[0059] see figure 1 Shown is the overall structure diagram of the first embodiment of the elevator drive sheave wear detection device of the present invention, the elevator drive sheave wear detection device includes an angular displacement detection device (driver) for detecting the elevator drive sheave angular displacement Sheave encoder 2), the line displacement detection device (code reader 14 and yardstick 13) that is used to detect elevator drive sheave line displacement and the elevator drive sheave angular displacement and line that detect according to described angular displacement detection device The wear calculation unit for calculating the wear and tear of the elevator drive sheave from the displacement of the elevator drive sheave line detected by the displacement detection device. The car 8 and the counterweight 9 are suspended in the elevator shaft by the driving rope 6 through the driving sheave 1 and the guide wheel 5 . Right below the car 8 and the counter...

Embodiment 2

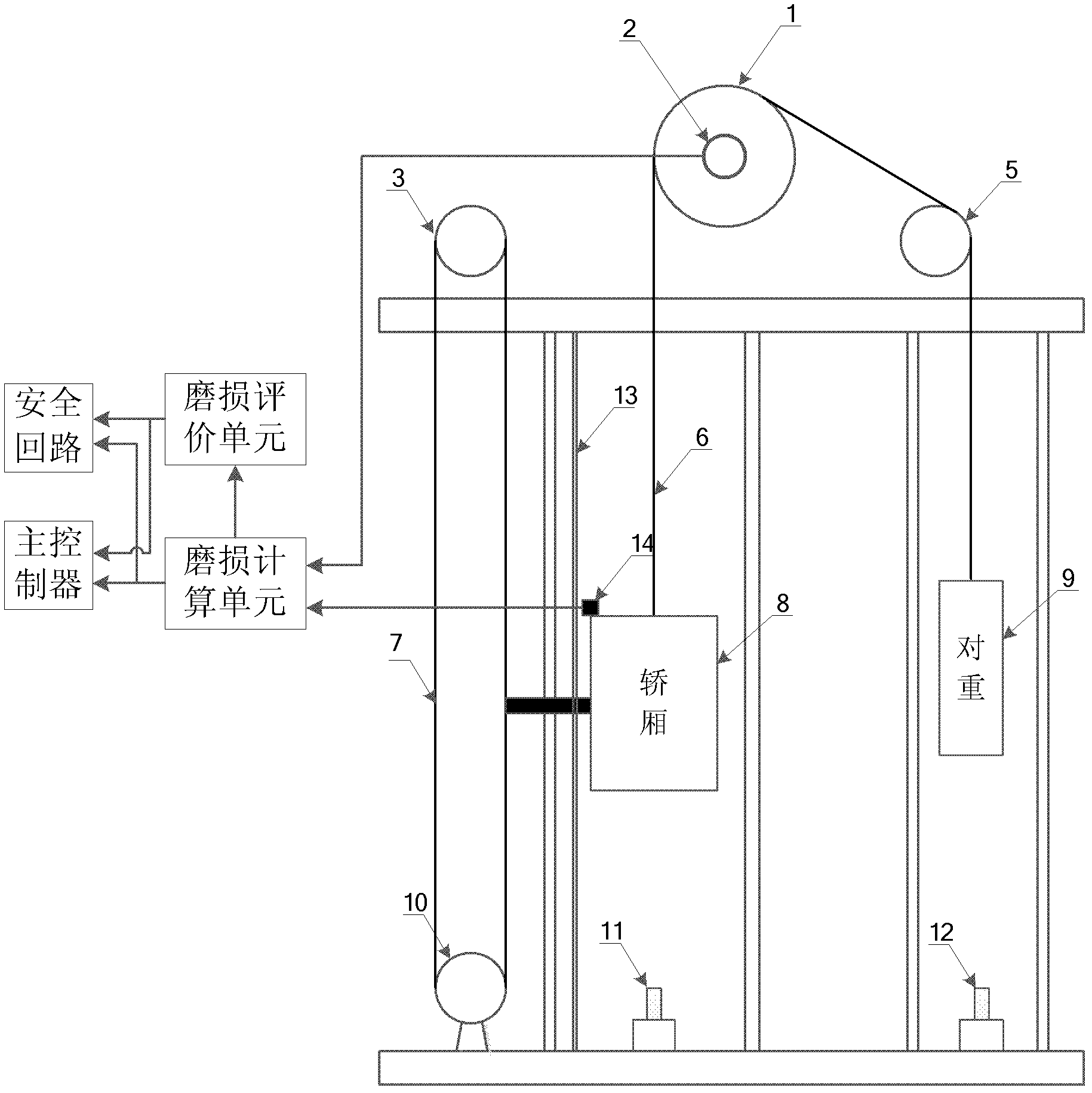

[0082] see figure 2 The overall structural schematic diagram of the second embodiment of the elevator drive sheave wear detection device of the present invention shown is different from Embodiment 1 in that it is used to evaluate the calculation results of the wear detection calculation unit and give The wear evaluation unit with the corresponding evaluation results will only be described below with regard to the differences from Embodiment 1.

[0083] The wear evaluation unit for evaluating the calculation result of the wear calculation unit evaluates the calculation result of the wear calculation unit according to a preset evaluation index, and gives a corresponding evaluation result. The evaluation index is a multi-segment interval index, such as: the allowable range of the diameter of the elevator driving sheave is 0~△D max , you can set 0~△D as needed max Divided into n (n≥2) intervals, namely 0~△D max1 、△D max1 ~△D max2 ,...,△D maxn-1 ~△D maxn , and then name eac...

Embodiment 3

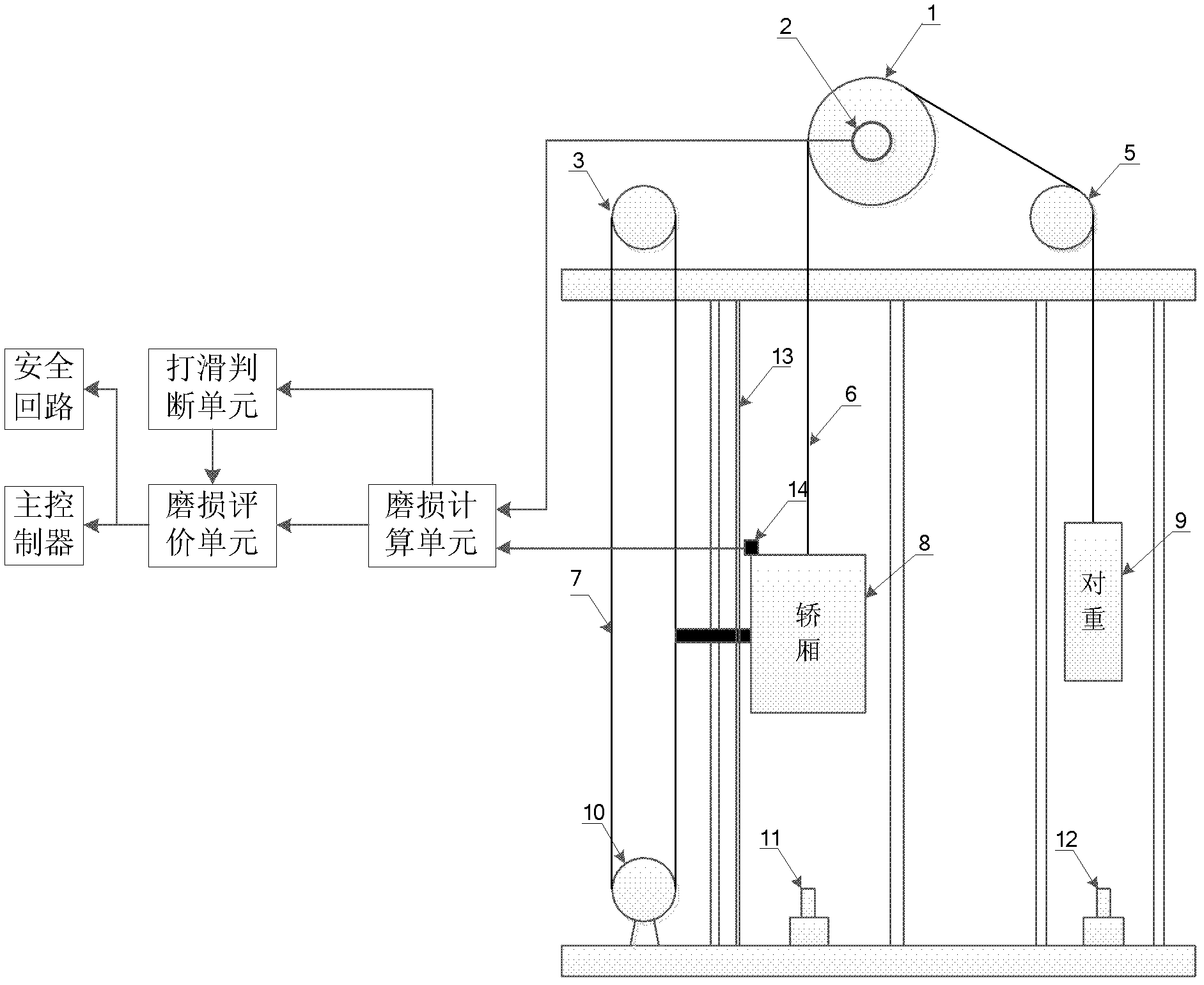

[0086] see image 3 The schematic diagram of the overall structure of the third embodiment of the elevator drive sheave wear detection device of the present invention is shown. The difference from Embodiment 2 is that the detection results based on the angular displacement detection device and the linear displacement detection device are added. The slipping judging unit for judging whether there is slipping between the elevator driving sheave and the driving rope will only be described below with regard to the differences from Embodiment 2.

[0087] The slip judgment unit judges whether there is slip between the elevator drive sheave and the drive rope according to one or more of the following methods:

[0088] Method 1: Using the linear displacement of the elevator driving sheave detected by the linear displacement detection device and the nominal value of the diameter of the elevator driving sheave to calculate the rotation angle of the elevator driving sheave, and combining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com