Automated drilling device with double main shafts

A drilling device and dual-spindle technology, applied in metal processing and other directions, can solve the problems of hand electric drill tool consumption, high risk factor, poor product accuracy, etc., and achieve the effect of overcoming low efficiency, high degree of automation, and reducing disability rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

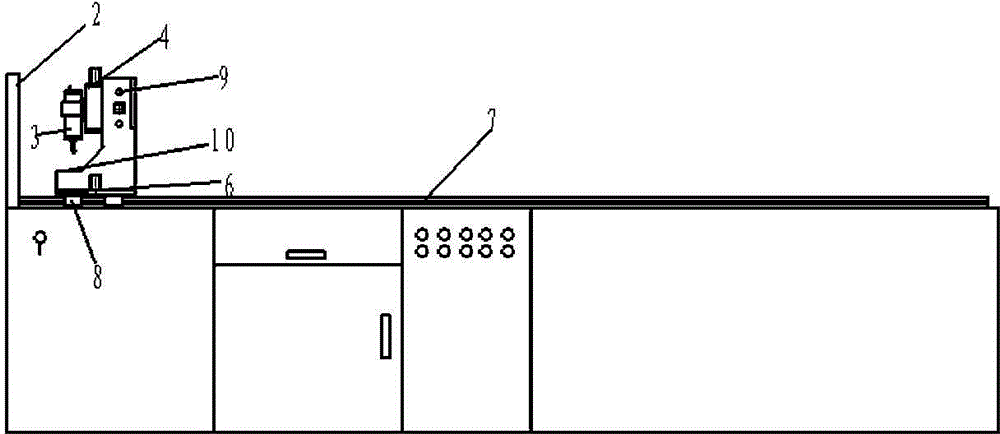

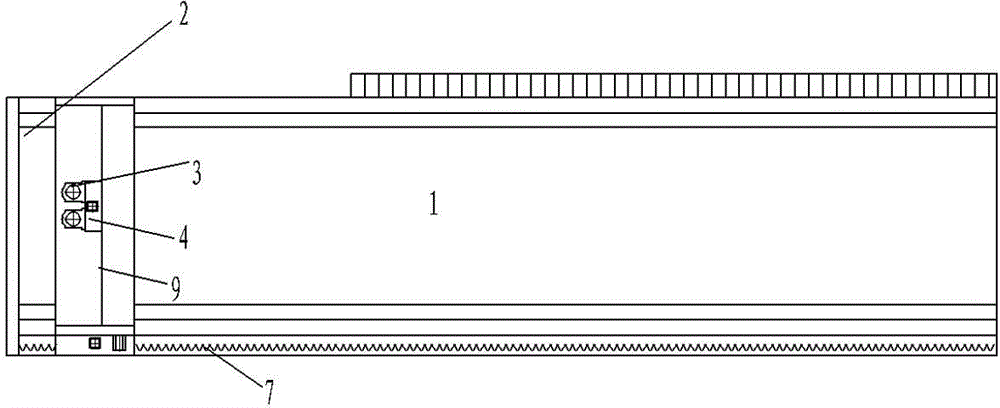

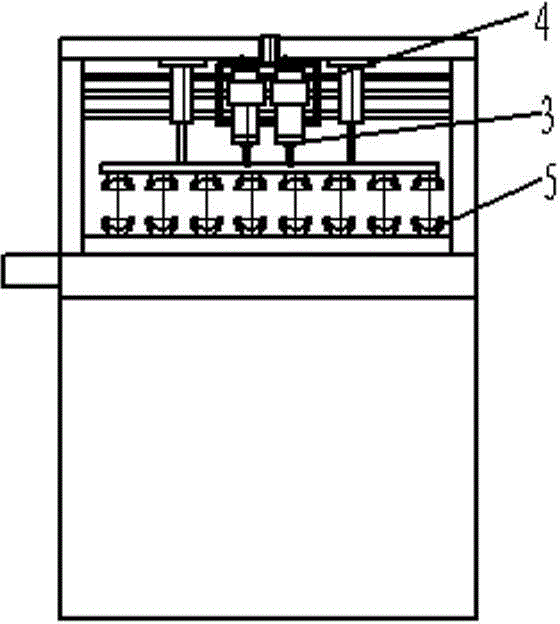

[0016] Such as figure 1 , 2 , an automatic double-spindle drilling device shown in 3, including a workbench 1, a pipe fixing frame 2, a clamping frame 4 holding a drilling rig 3, a longitudinal moving device and a horizontal screw drive mechanism are installed above the workbench 1 9; the pipe fixing frame 2 includes a pipeline holding card composed of two semicircular holding plates 5 installed at one end of the workbench 1 and a support rod 6 installed under the clamping frame 4; the longitudinal movement The device includes a rack 7 longitudinally fixed on both sides of the workbench 1, a gear 8 fixed on both sides of the bottom of the clamping frame 4 and matched with the rack 7, and the gear 8 is connected to the motor I; the clamping frame 4 is fixed On the transverse screw drive mechanism 9, the transverse screw drive mechanism 9 is connected with the motor II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com