adjustable wrench

A technology of adjustable wrench and wrench, which is applied in the field of wrench, can solve the problems of small torque and slow speed of worm gear, achieve the effect of reducing the requirement of matching precision and improving force component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

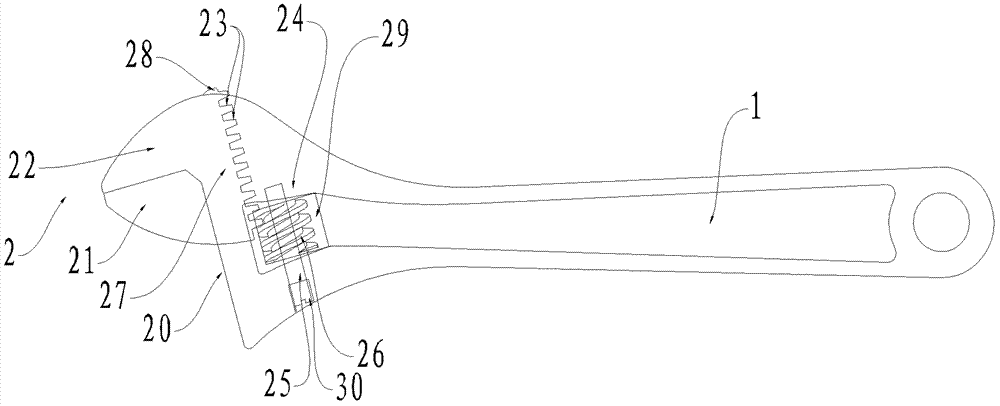

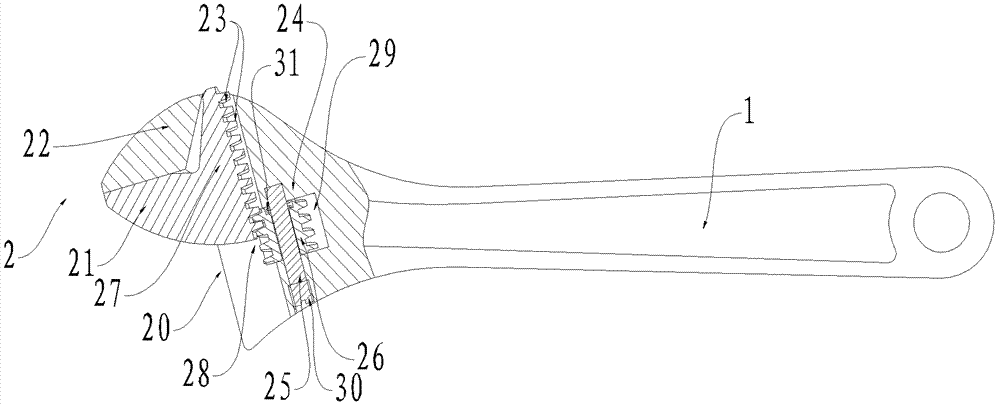

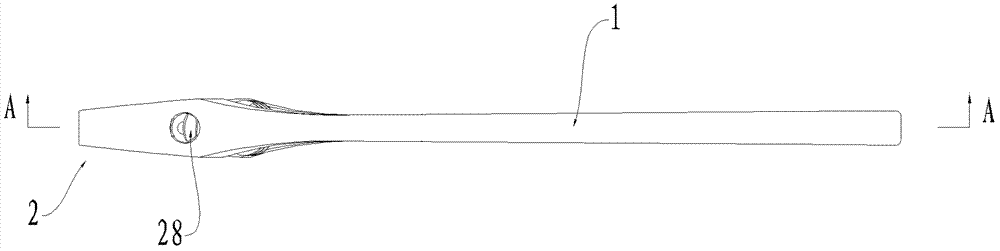

[0029] Such as figure 1 As shown, the adjustable wrench of the first embodiment of the present invention includes a wrench body and a worm gear 24 , and the wrench body includes a handle 1 and a working part 2 . The working part includes a fixed part 22 , a movable part 21 and a chute 20 . The fixing part 22 is located at the upper end of the wrench body and at the side of the wrench body. The chute 20 is close to one end of the fixing portion 22 and extends laterally. Both ends of the chute 20 are open, and a part of the upper end of the chute 20 is also open.

[0030] The lower end of the movable part 21 is disposed in the slide slot 20 to move toward or away from the fixed part 22 . The lower end of the movable part 21 includes a neck 27 and a slider 28 , the slider 28 is located at the bottom of the neck 27 and is roughly cylindrical. The neck 27 and the slider 28 are arranged in the chute 20 . On the bottom edge of the slider 28 , there is provided a tooth portion 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com