Non-destructive disassembly device for compressor rotor shrink sleeve assembly

A compressor rotor and heating device technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of rotor aluminum end ring, crankshaft long shaft crankcase deformation damage due to force, rotor aluminum leakage and deformation, interference If there are problems such as large matching amount, it can achieve the effect of uniform heating, reducing ejection force and reducing interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

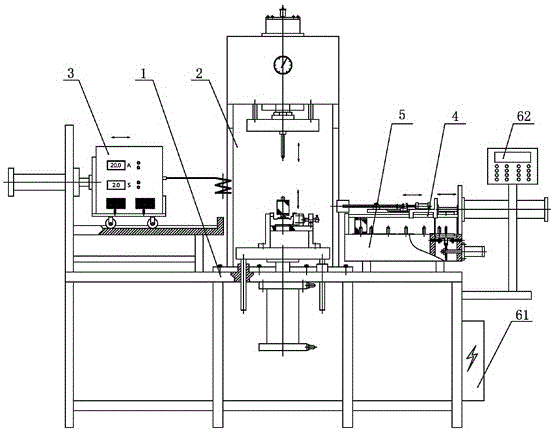

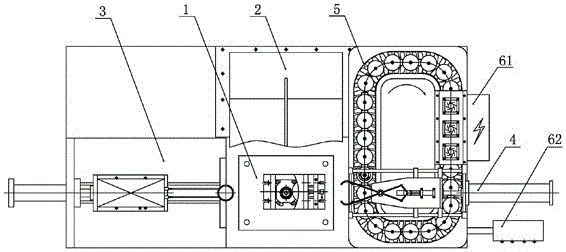

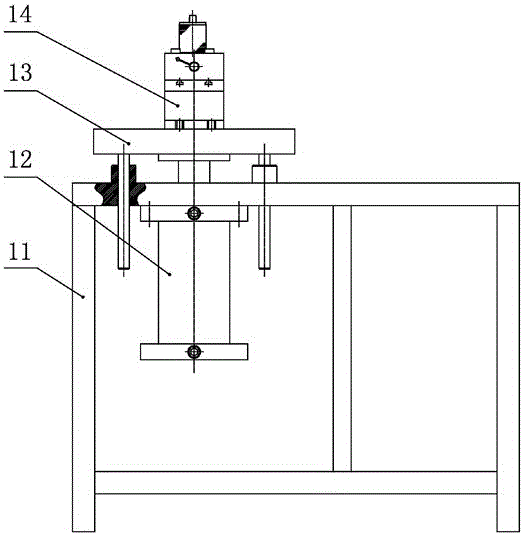

[0024] Such as figure 1 with figure 2 As shown, a non-destructive disassembly device for a compressor rotor shrink sleeve assembly, including a frame, and a jacking mechanism 1 installed on the frame, a hydraulic ejection mechanism 2, a high-frequency heating device 3, a rotor transfer mechanism 4, and a rotor Cooling mechanism 5 and control mechanism 6. The top of the jacking mechanism 1 is provided with a clamping fixture 14; the high-frequency heating device 3 is arranged on the upper left part of the jacking mechanism 1, which can move left and right and heat the workpiece; the hydraulic ejector mechanism 2 is arranged on the jacking mechanism 1 and the high-frequency heating Above the device 3, its pressure center coincides with the center of the jacking mechanism 1; the rotor transfer mechanism 4 is arranged on the upper right part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com