A combined multi-point die shape adjustment device for sheet metal

A combined, sheet metal technology, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high technical level requirements, high equipment cost, complex structure, etc., to simplify the structure, shorten the development cycle, and reduce the manufacturing cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as Image 6 As shown, a combined sheet metal multi-point mold shape adjustment device includes a basic body and its adjustment mechanism 1, an inner guard plate 2, an outer guard plate 3, a supporting pad 4 and an electromagnet 5; the basic body and Its adjustment mechanism 1, the inner guard plate 2, and the outer guard plate 3 are all arranged on the support pad 4, and the electromagnetic adsorption force is provided by the electromagnet 5 arranged at the bottom of the support pad 4, and the basic body and its adjustment mechanism 1, The inner guard plate 2 and the outer guard plate 3 are fixed on the support pad 4;

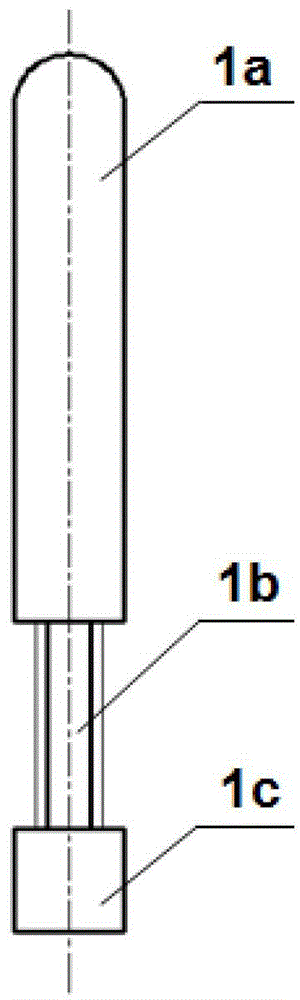

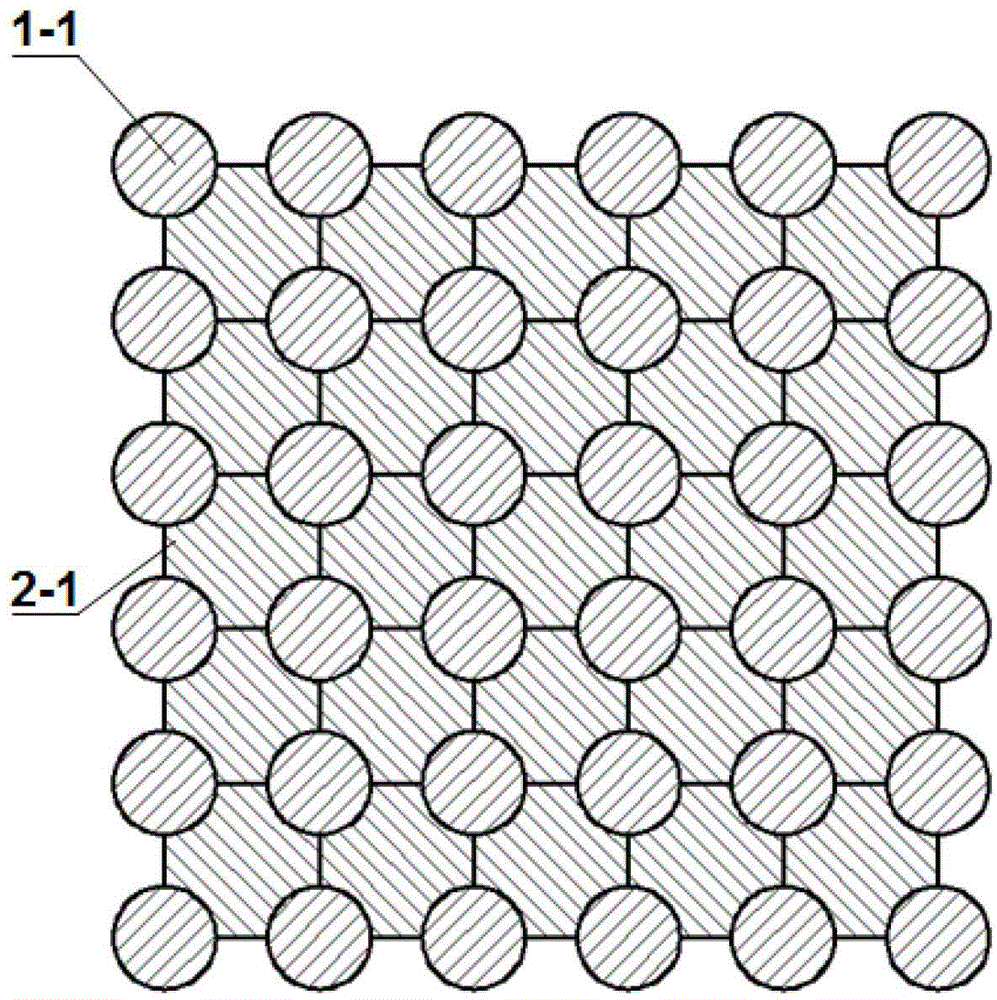

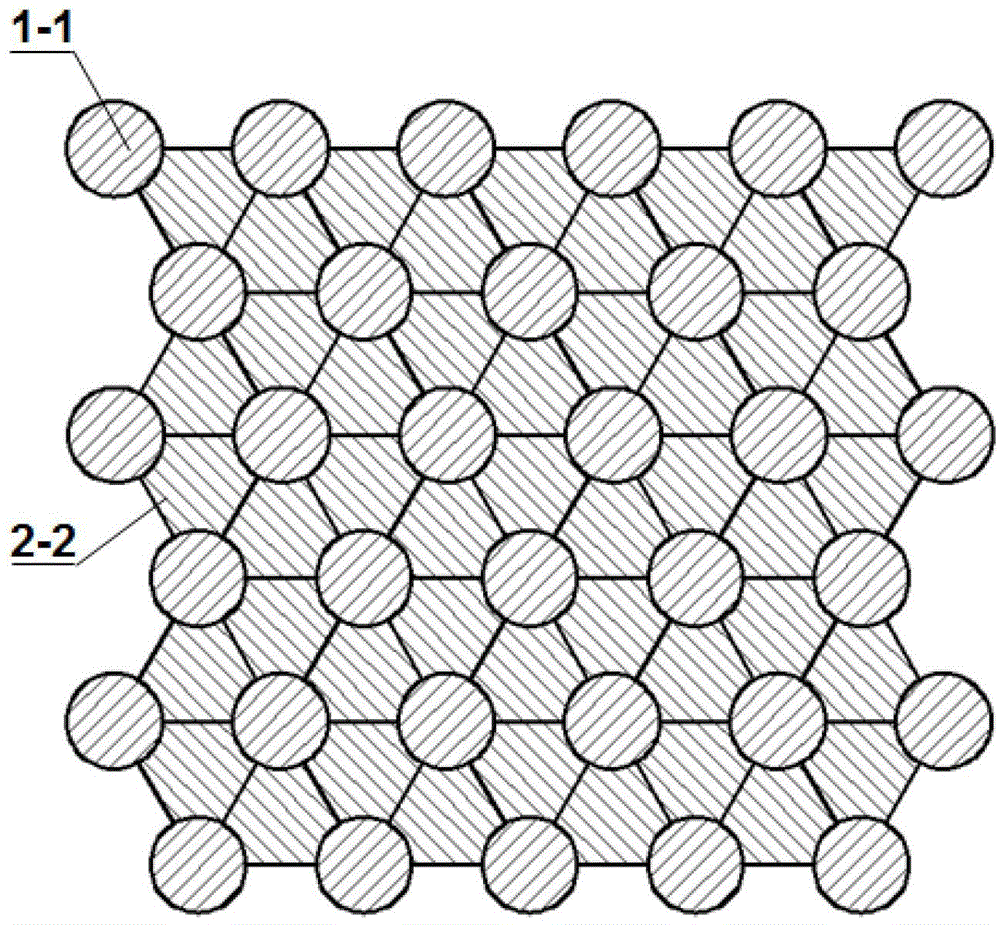

[0027] Among them: such as figure 1 As shown, the basic body and its adjustment mechanism 1 include a basic body 1a, a fixed screw 1b and a base 1c, the basic body 1a is connected to the base 1c through the fixed screw 1b, and the height of the basic body 1a is adjusted through the fixed screw 1b. The inner side guard plate 2 and the outer side gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com