Technology for removing SO2 in smoke through recovery method

A technology of SO2 and desulfurization process, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve problems such as failure to realize resource recycling, complex process flow, and large consumption of desulfurization agents, etc., to achieve stable operation, Low energy consumption and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

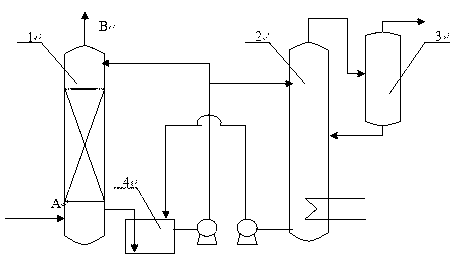

[0022] The absorption reaction technological process of present embodiment is as figure 1 shown. The desulfurization tower (1) is a spray tower with a diameter of 200mm, and the desulfurization tower (2) is a 50L magnetically stirred tank type desorption tower. The flue gas enters the desulfurization tower from inlet A at the lower part of the desulfurization tower (1), and contacts with the zinc sulfite slurry sent into the desulfurization tower by a circulating pump to complete SO 2 Absorption, the rich liquid is discharged from the lower part of the desulfurization tower into the slurry pool (4). When the desulfurizer is consumed to a certain extent, the rich liquid is split and sent to the desorption tower (2) for SO 2 Analysis and absorbent regeneration. Flue gas without dust, the flow rate is 300m 3 / h,SO 2 The concentration is 2000mg / m 3 , oxygen content 5%. At a temperature of 20°C and a liquid-to-gas ratio of 12 in the desulfurization tower, after treatment wit...

Embodiment example 2

[0024] SO in flue gas 2 The concentration is 8000mg / m 3 , using the same process as Case 1, after being treated with a zinc sulfite solution with a concentration of 18% in the absorbing fluid of the desulfurization tower, the SO in the purified gas 2 The content is 700mg / m 3 , the desulfurization efficiency is up to 92%. After heating in the desorption tower at 60°C for 1 hour, more than 92% of the zinc sulfite in the rich liquid is regenerated, and the SO in the regeneration gas 2 The content is 95%, and the regeneration recovery rate of zinc sulfite in the absorption liquid reaches 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com