Natural latex dewatering device

A dehydration device, natural latex technology, applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve the problems of poor performance, reduce the overall moisture content of mixed latex, reduce the proportion of oak protein, etc., to achieve water content reduction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

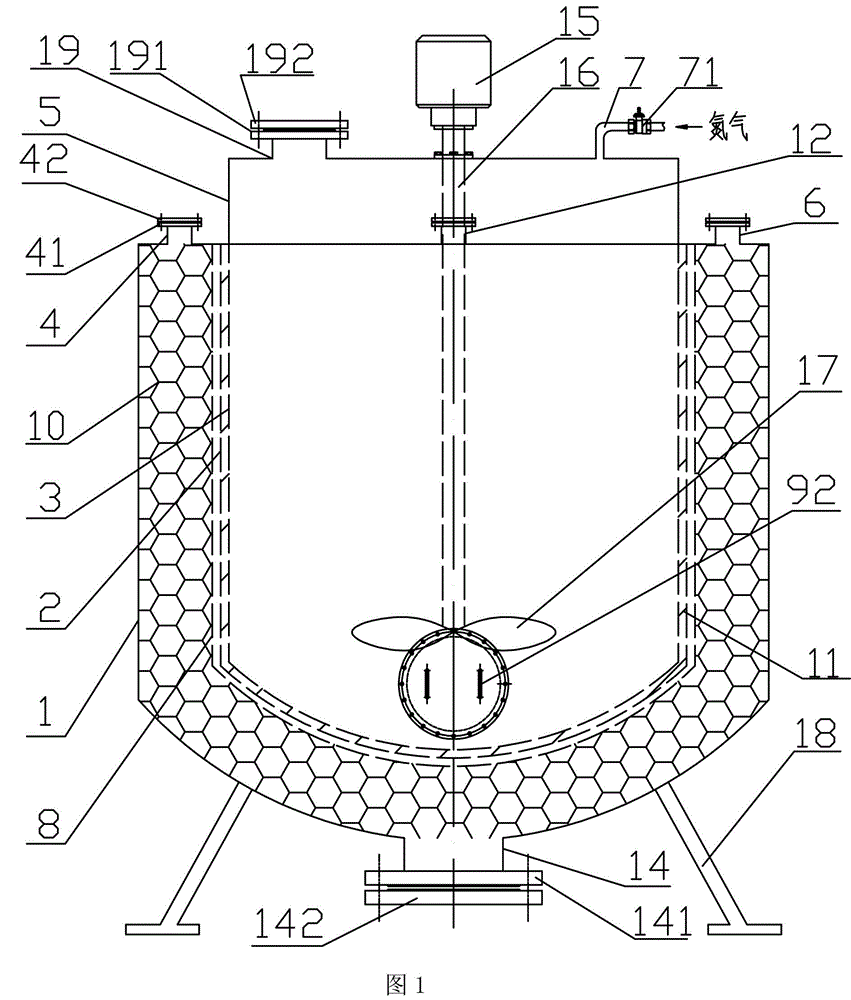

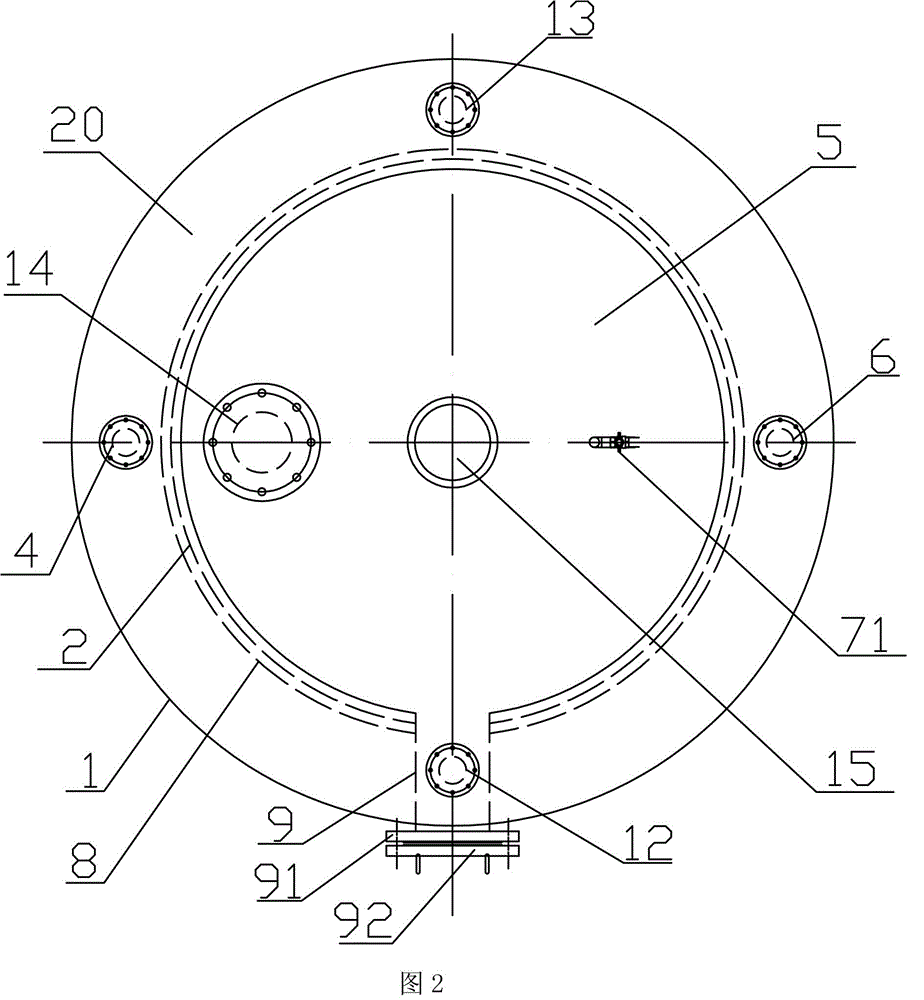

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

[0013] Such as figure 1 , figure 2 The shown natural latex dehydration device includes a cylinder 1 provided with a jacket, a molecular sieve 10 is arranged in the jacket, and the inner wall of the cylinder includes a first stainless steel mesh plate 3 and a second stainless steel mesh plate 2 arranged sequentially from inside to outside, There is a gap between the first stainless steel net plate 3 and the second stainless steel net plate 2, in the gap is provided with filter cotton 11 that allows water to pass through but the latex cannot pass through, and on the first stainless steel net plate 3 side walls is provided with a filter cotton that extends to The latex discharge pipe 9 on the outer wall of the cylinder body 1 is welded with a flange 91 on the latex discharge pipe 9, and the flange cover plate 92 is connected to the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com