Trigger type sparkgap and control method thereof

A spark gap and trigger control technology, applied in the field of electric equipment, can solve the problems of low stability and reliability of spark gap trigger discharge, unfavorable reliable operation of the gap, and high ignition discharge voltage, so as to improve the protection coordination performance and eliminate the polarity. effect, the effect of reducing the voltage value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

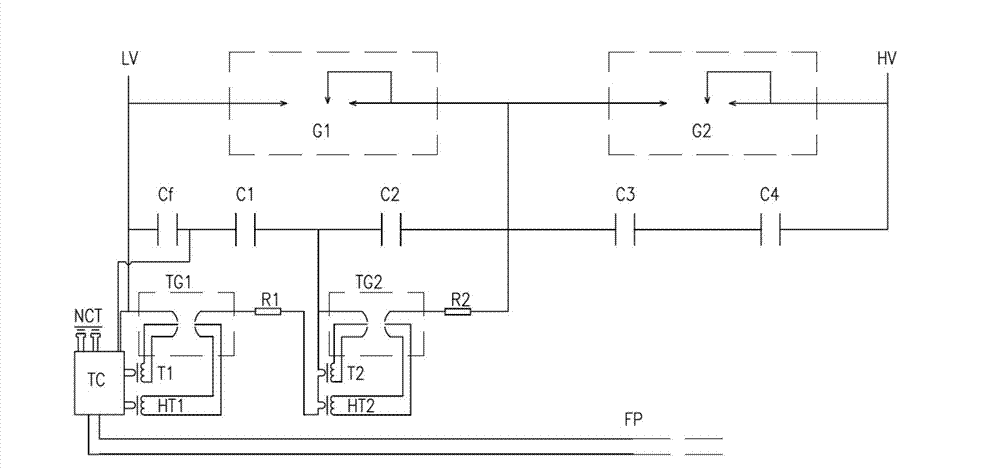

[0033] The structural diagram of a triggered spark gap provided in this embodiment is as follows figure 1 As shown, it includes gap triggering system, self-discharging main gap G1, self-discharging main gap G2, voltage dividing capacitor Cf and voltage equalizing capacitors C1~C4, self-discharging main gap G1 and self-discharging main gap G2 are formed in series The main gap branch is connected to the low-voltage end and high-voltage end of the grid respectively; the voltage dividing capacitor Cf and the voltage equalizing capacitor are connected in parallel with the main gap branch; the gap trigger system is connected to the low-voltage end of the main gap branch. Self-discharge type main gap ( figure 1 In the self-discharge type main gap G1) in parallel.

[0034] Self-discharging main gaps include metal casings, flas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com