Optical compensation continuous zooming passive athermalization optical system

An optical system and optical compensation technology, applied in the field of optical design in the near-infrared band, can solve the problems of not realizing optical passive athermalization, not realizing athermal design, etc., achieving good tolerance characteristics, good ability to correct chromatic aberration, and volume. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further clearly illustrate the characteristics of the technical solution, a best implementation mode of the specific implementation mode of the present invention is provided below in conjunction with the accompanying drawings to illustrate the present invention, but it should not be construed as a limitation of the present invention.

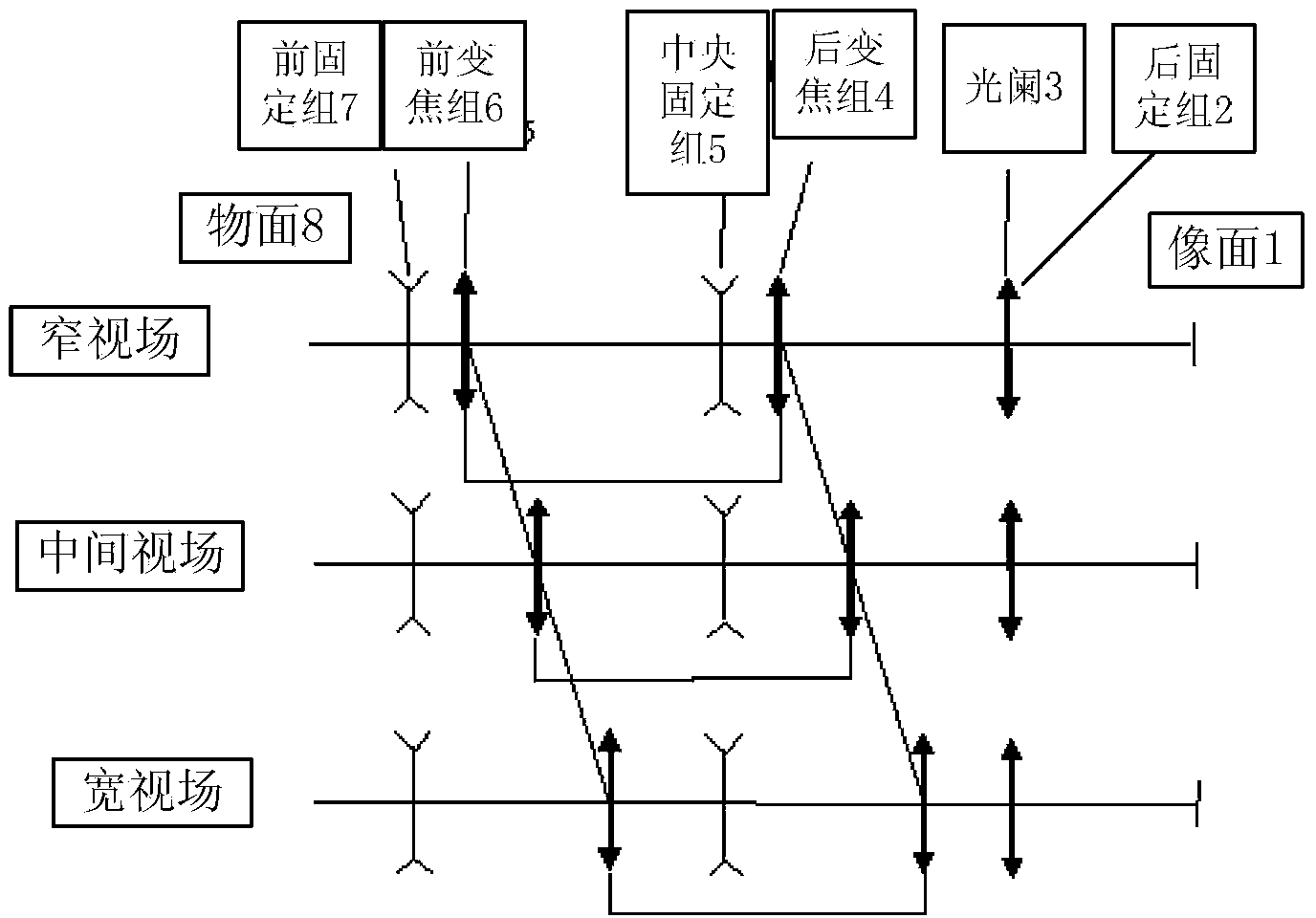

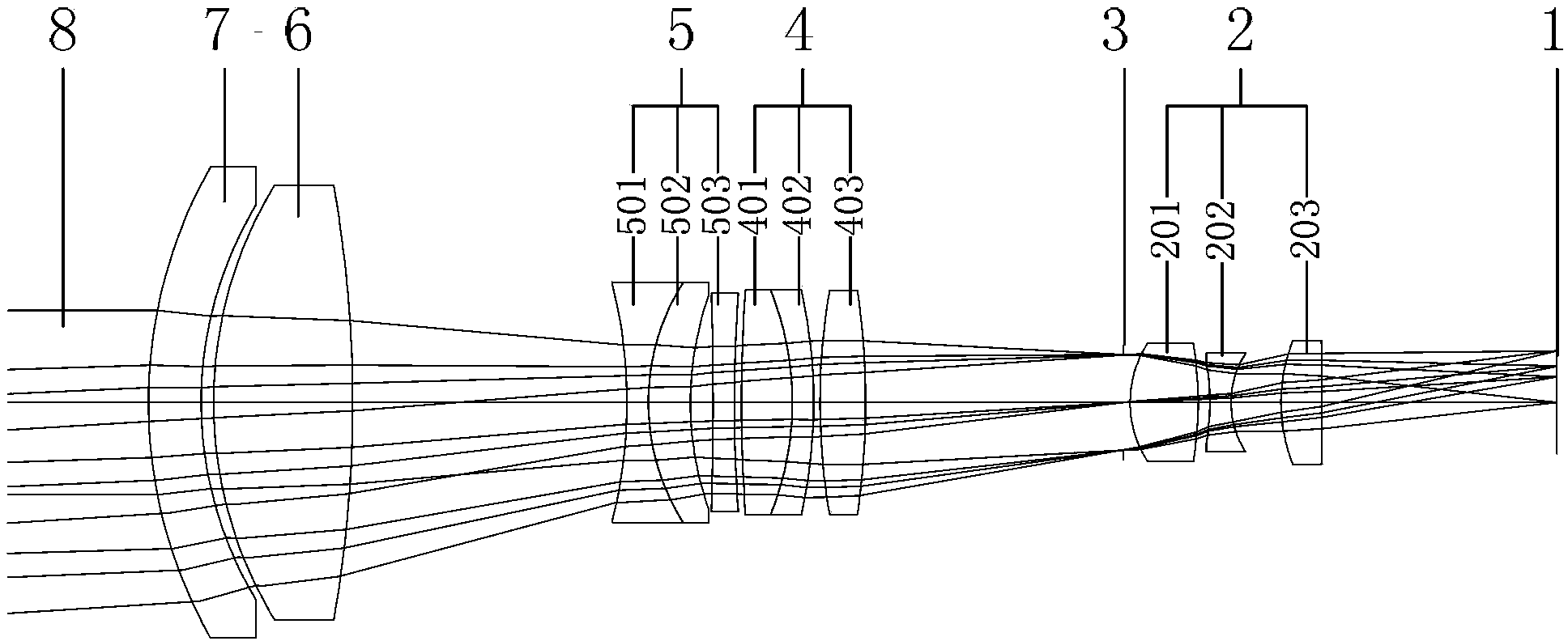

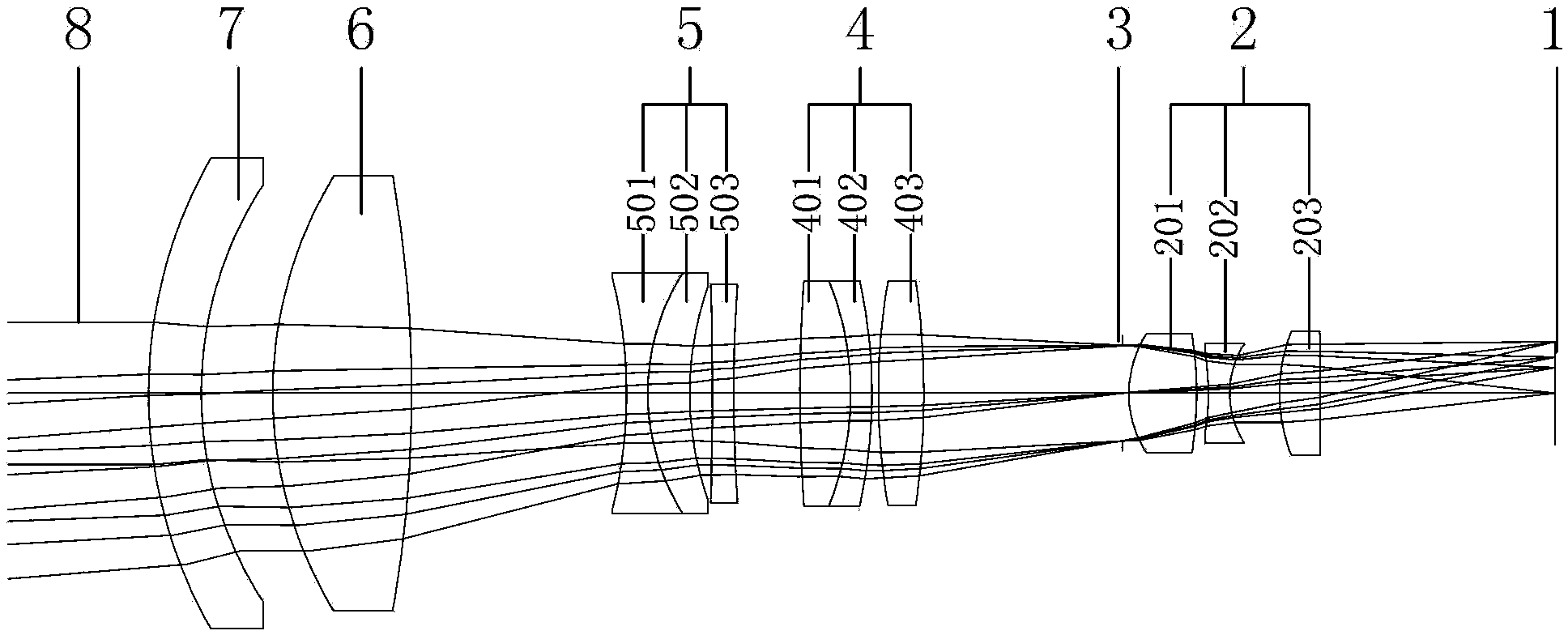

[0021] refer to figure 1 . The ideal lens model optical system has a constant total length from the image plane 1 to the front fixed mirror group 7 during the zooming process, wherein, the front fixed mirror group 7, the central fixed mirror group 5, the diaphragm 3, the rear fixed mirror group 2 and the image The position of the surface 1 is constant; the central spacing of the two moving mirror groups, namely the front zoom mirror group 6 and the rear zoom mirror group 4, also remains constant. During the zooming process, the front zoom lens group 6 and the rear zoom lens group 4 are linked back and forth on the optical axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com