Modularized joint displacement sensor applied to robot

A technology of modular joints and displacement sensors, applied in the field of displacement sensors, can solve problems such as unfavorable installation and maintenance, general sensors cannot meet the special requirements of robots, and cumbersome, and achieves improved operating comfort, convenient wiring, and flexible installation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

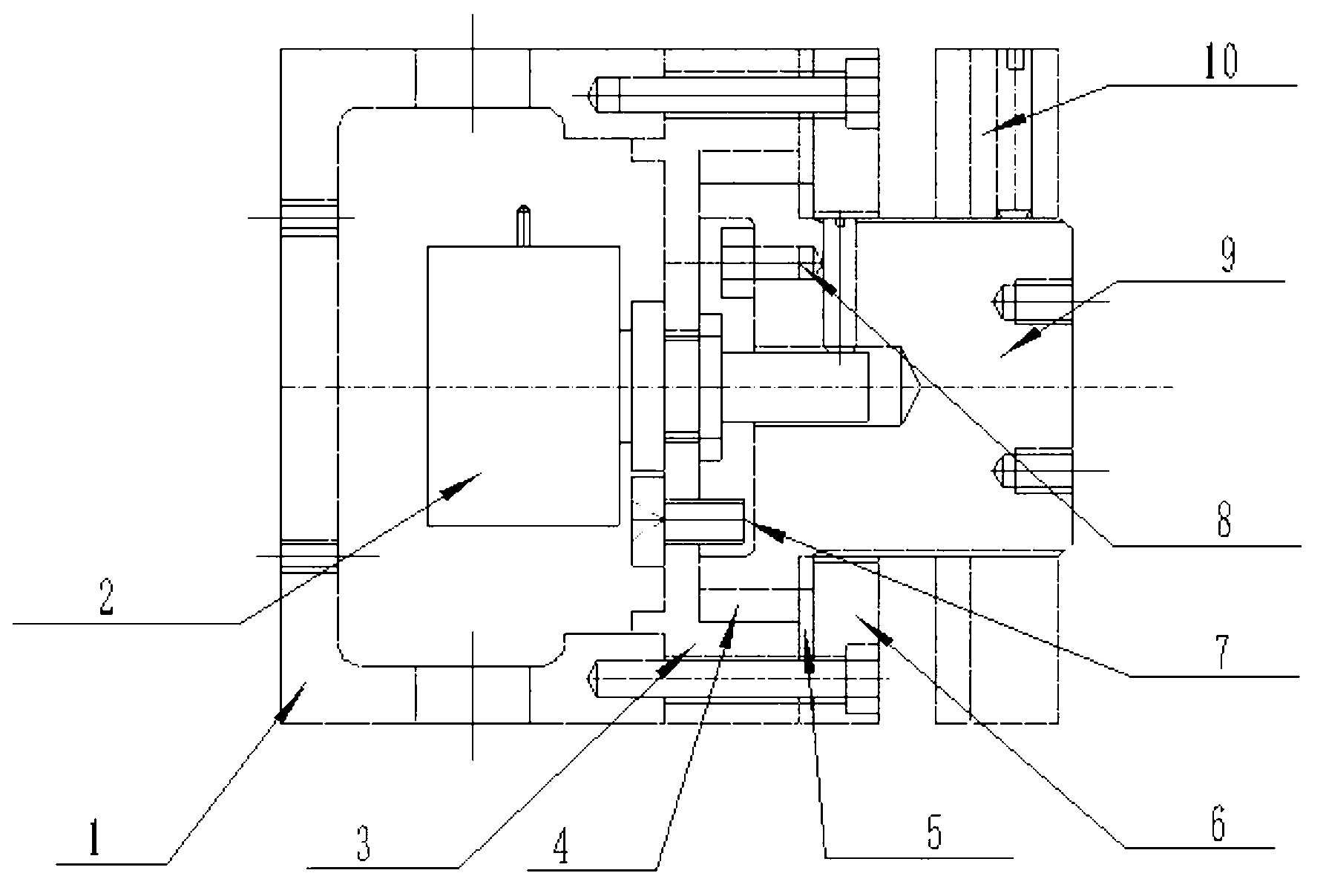

[0030] Such as figure 1 As shown, the present invention includes a housing 1 with one side opening and an output shaft 9 fixed at the opening of the housing 1 through a sliding bearing. The sliding bearing includes a bearing seat 3 and a bearing cover 6, and the housing 1 is provided with a fixed bearing seat 3 The limit screw II7, the housing 1 is fixed on the frame, the output shaft 9 is fixed on the rotating part, the interior of the housing 1 is installed with a linear potentiometer 2, and the lower and upper sides of the housing 1 are respectively provided with for input and output. Out of the hole for the cable, the cable is soldered to the linear potentiometer 2. The potentiometer shaft of the linear potentiometer 2 passes through the bearing seat 3 and is stuck in the output shaft 9. There is a gap between the output shaft 9 and the end of the potentiometer shaft to ensure that the potentiometer shaft only bears torque and does not bear axial or radial loads; Moreover...

Embodiment 2

[0034] The output shaft 9 is fixed on the frame, the housing 1 is fixed on the rotating part, and the output shaft 9 drives the potentiometer shaft to rotate, thereby converting the rotation of the output shaft 9 into an electrical signal. The other parts are the same as those in Embodiment 1 and will not be described in detail.

[0035] The present invention is equally applicable to other automatic devices that have the same requirements as robots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com