Electro-hydraulic gate valve

A plug-in valve, electro-hydraulic technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of poor sealing effect at the guide rail, and achieve good sealing performance, high wear resistance, flexible and reliable valve opening and closing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

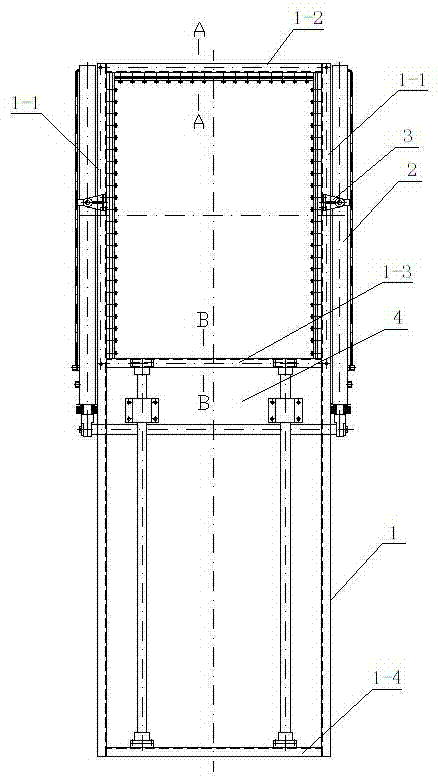

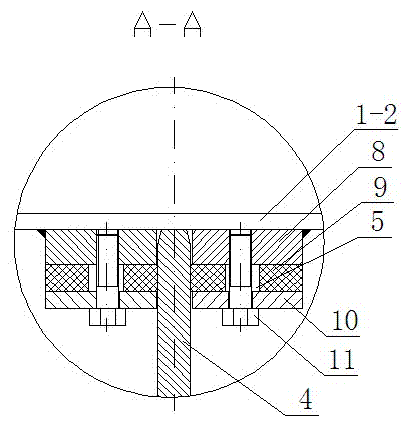

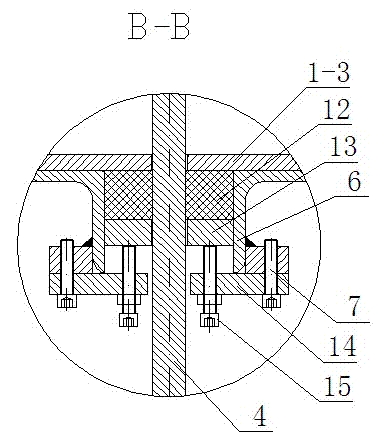

[0010] Such as figure 1 As shown, it is an electro-hydraulic slide valve, including a frame 1, and the frame 1 includes two vertical plates 1-1, and one end of the two vertical plates 1-1 is connected by a first horizontal plate 1-2, and the two vertical plates 1-1 The other end of -1 is connected by the second horizontal plate 1-4, and two intermediate plates 1-3 are arranged between the first horizontal plate 1-2 and the second horizontal plate 1-4, and the two intermediate plates 1-3 The two ends are respectively connected with the corresponding vertical boards 1-1. Each vertical plate 1-1 is respectively connected to the oil cylinder support 3, and each oil cylinder support 3 is respectively connected to the oil cylinder 2, and an inserting plate 4 is arranged between the two oil cylinders 2, and the inserting plate 4 is arranged on two intermediate plates 1-3 Between, the telescoping end of two oil cylinders 2 is connected with inserting plate 4 respectively.

[0011] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com