A Model-Based Decoupling and Anti-disturbance Control Method for HCCI Combustion

A technology of decoupling control and control methods, applied in electrical control, engine control, machine/engine, etc., can solve problems such as cumbersome calculation of adaptive control, complex HCCI combustion process, and difficulty in accurate modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

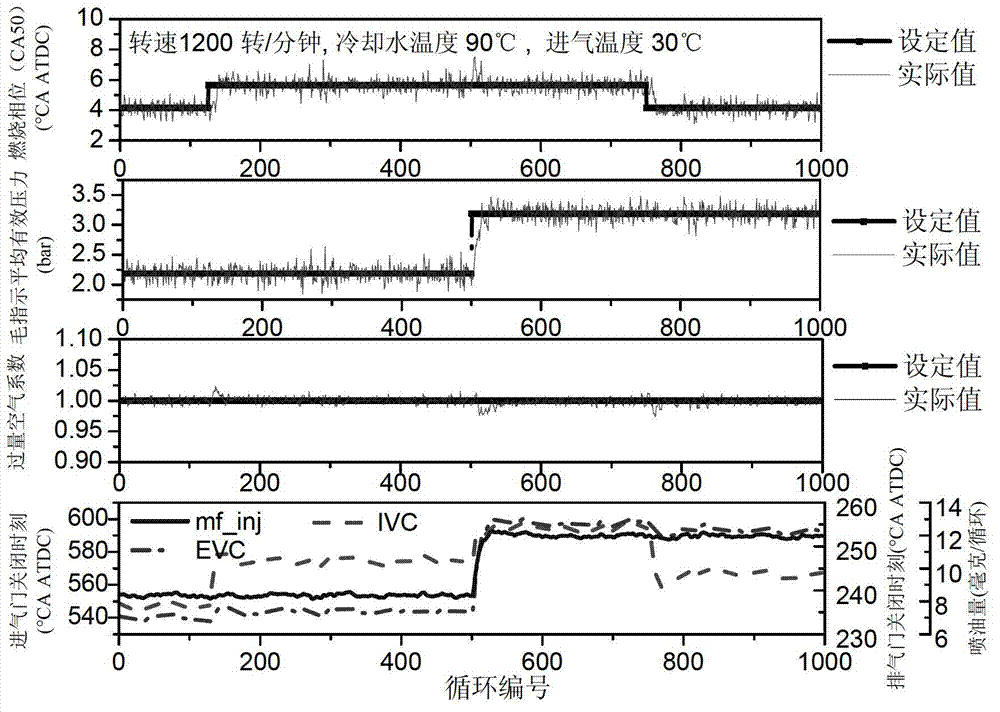

[0098]Below, based on a simulation platform of a single-cylinder HCCI gasoline engine, the engine parameters thereof are as shown in Table 1, introducing the best embodiment of the present invention. For a more detailed description of the simulation platform, please refer to: Qin Jing, Xie Hui, Zhang Yan, Zhao Hua, "A Combustion Heat Release Correlation for CAI Combustion Simulation in 4-Stroke Gasoline Engines", SAE 2005-01-0183.

[0099] The specific implementation steps are detailed as follows:

[0100] Table 1: Engine parameters used in embodiments of the present invention

[0101] Cylinder diameter [mm] 86 stroke [mm] 86 Displacement [L] 0.5 compression ratio 10.66 combustion chamber Bonnet / 4 valves fuel injection method port injection fuel type No. 93 gasoline Intake pressure 1 bar Throttle Opening 100%

[0102] Step 1: Establishment of the control model of HCCI combustion:

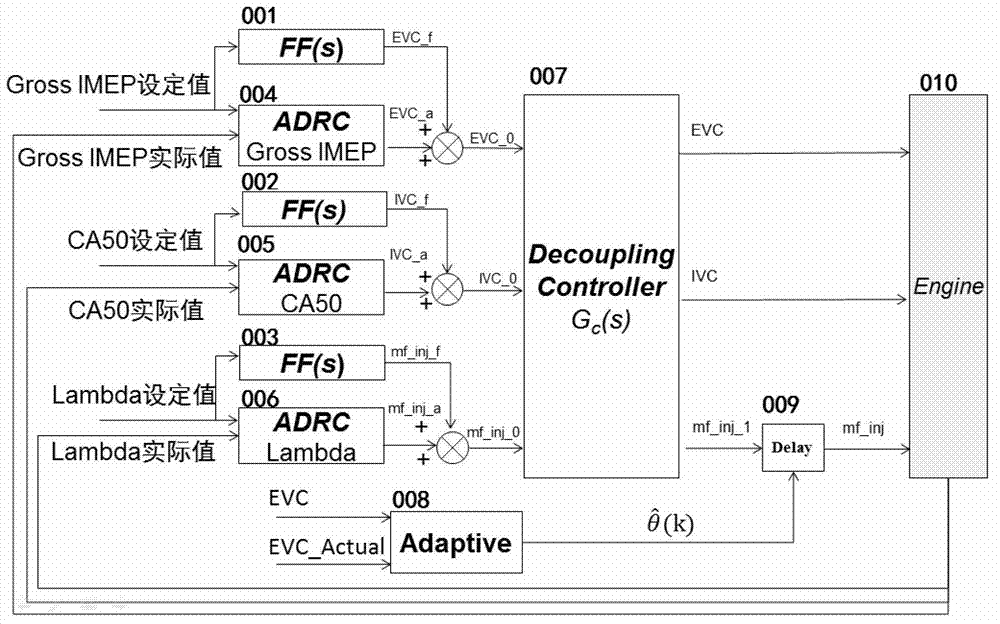

[0103] like figure 1 Show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com