Preparation method of MIL-100(Fe) packaged phosphotungstic heteropolyacid catalyst

A phosphotungstic heteropolyacid and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve harsh conditions and supported heteropolyacid catalysts The problems of low yield, etc., achieve the effects of low synthesis temperature and pressure, high catalyst synthesis yield, and low synthesis energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

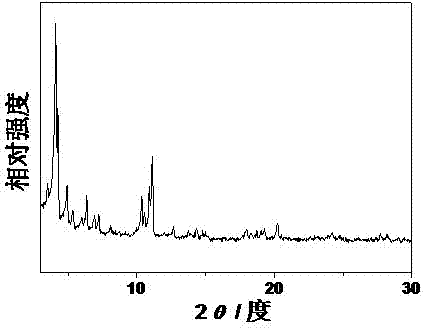

Embodiment 1

[0024] Add 0.34 g of sodium tungstate and 0.012 g of disodium hydrogen phosphate into a three-necked flask filled with 5 mL of deionized water, and then add 2.02 g of Fe(NO 3 ) 3 . 9H 2 O, after magnetic stirring for about 30 min, add 0.70 g of 1,3,5-benzenetricarboxylic acid, stir for 30 min, add 0.5 mL of 1 mL / L hydrofluoric acid dropwise, continue stirring for 1 h, reflux to condense, and heat up to 95 °C Afterwards, the constant temperature was maintained for 12 h, and the reactor was a three-necked flask with a reflux condenser. After the reaction, the samples were filtered, washed with a sufficient amount of deionized water, and dried in a drying oven at constant temperature for 5 h.

[0025] The dried samples were further purified with ethanol and ammonium fluoride, respectively. First, treat with absolute ethanol at 70 °C for 10 h, then treat with 30 mmol / L ammonium fluoride solution at 80 °C for 10 h, and finally wash thoroughly with deionized water. The drying t...

Embodiment 2

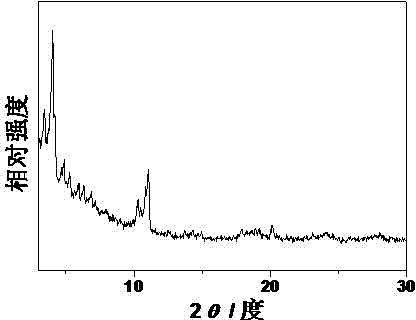

[0027] Add 0.21 g of sodium tungstate and 0.0074 g of disodium hydrogen phosphate into a three-necked flask filled with 15 mL of deionized water, and then add 0.81 g of FeCl 3 . 6H 2 O, after magnetic stirring for about 30 min, add 0.51 g of 1,3,5-trimethylbenzenetricarboxylate, stir for 30 min, add 0.5 mL of 1 mL / L hydrofluoric acid dropwise, continue stirring for 1 h, reflux to condense, and heat up After reaching 95 °C, keep the constant temperature for 12 h, and the reactor is a three-necked flask with a reflux condenser. After the reaction, the samples were filtered, washed with a sufficient amount of deionized water, and dried in a drying oven at constant temperature for 5 h.

[0028] The dried samples were further purified with ethanol and ammonium fluoride, respectively. First, treat with absolute ethanol at 60 °C for 15 h, then treat with 40 mmol / L ammonium fluoride solution at 70 °C for 15 h, and finally wash thoroughly with deionized water. The drying temperatur...

Embodiment 3

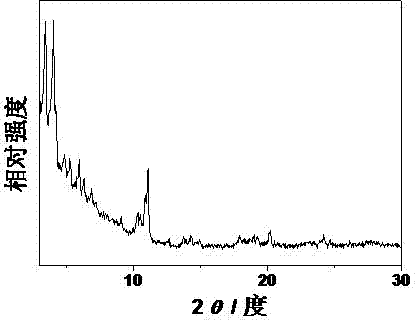

[0030]Add 0.34 g of sodium tungstate and 0.012 g of disodium hydrogen phosphate into a three-necked flask filled with 5 mL of deionized water, and then add 2.02 g of Fe(NO 3 ) 3 . 9H 2 O, after magnetic stirring for about 30 min, add 0.63 g of 1,3,5-trimethylbenzenetricarboxylate, stir for 30 min, add 0.5 mL of 1 mL / L hydrofluoric acid dropwise, continue stirring for 30 min, reflux to condense, and heat up After reaching 80 °C, keep the constant temperature for 20 h, and the reactor is a three-necked flask with a reflux condenser. After the reaction, the samples were filtered, washed with a sufficient amount of deionized water, and dried in a drying oven at constant temperature for 5 h.

[0031] The dried samples were further purified with ethanol and ammonium fluoride, respectively. First, treat with absolute ethanol at 80 °C for 20 h, then treat with 50 mmol / L ammonium fluoride solution at 60 °C for 10 h, and finally wash thoroughly with deionized water. The drying temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com