A device for controlling the pivoting blades of a turbine

A technology for control devices and turbines, which is applied to components, mechanical equipment, engine components, etc. of elastic fluid pumping devices. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

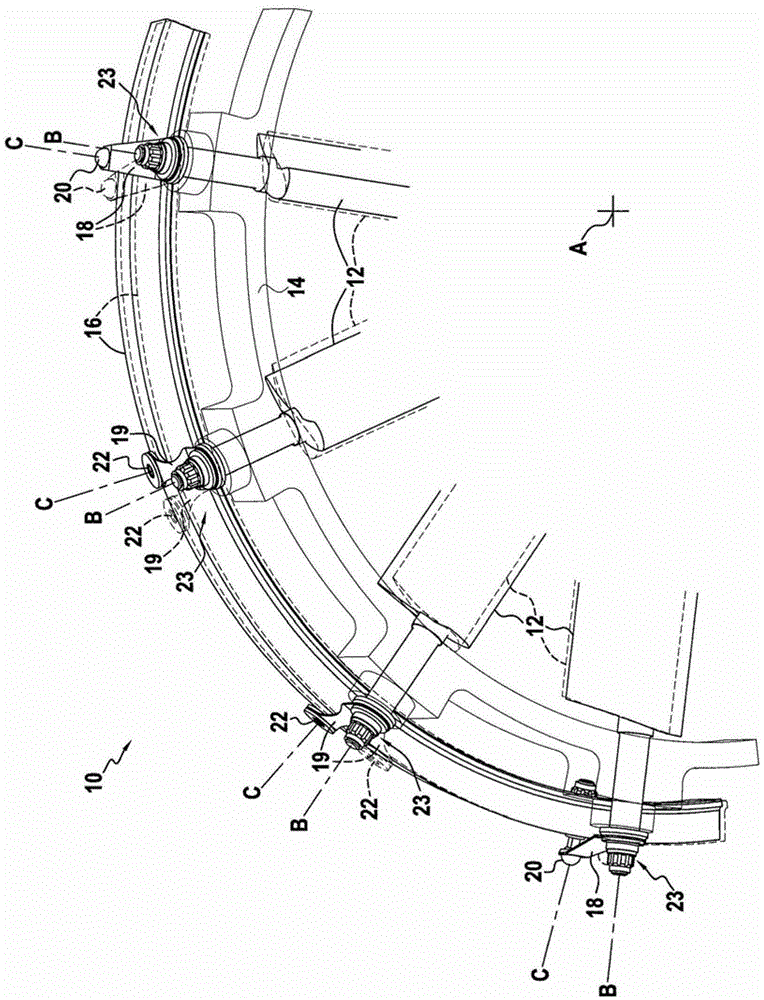

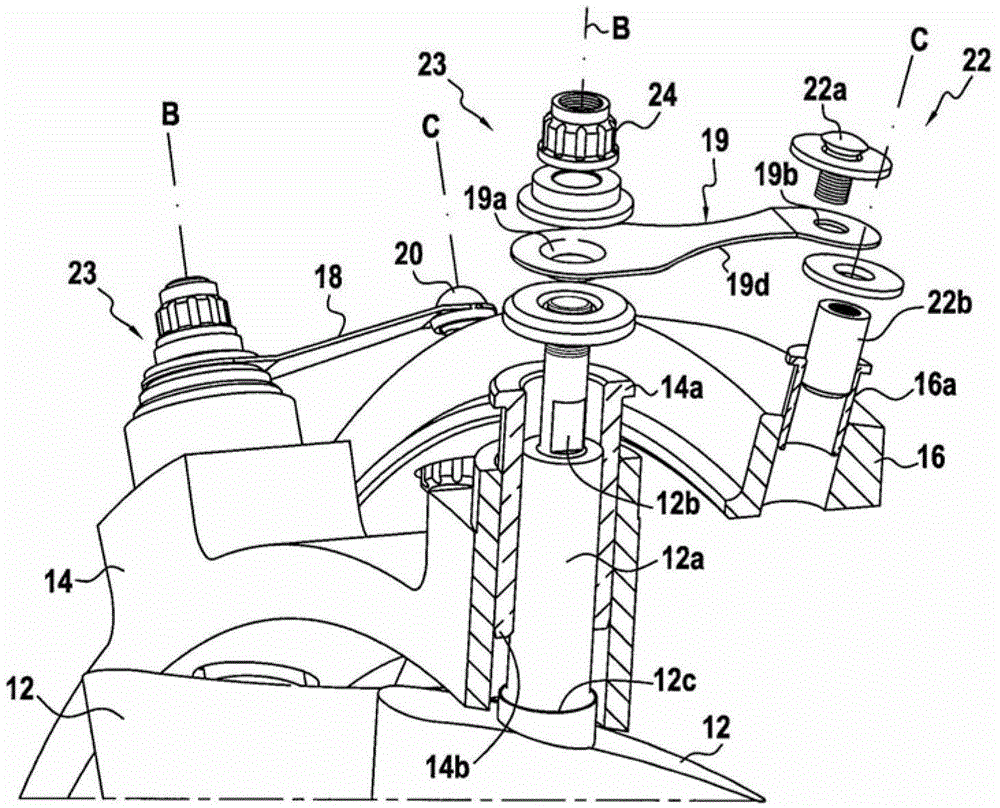

[0038] figure 1 An embodiment of the control device of the invention for controlling pivoting blades of a turbomachine is shown. In this embodiment, the blades are oriented radially with respect to the turbine axis. The schematic diagram shown is a partial one, the whole arrangement extending 360° around the axis A of the turbine (not shown). This axis A forms the longitudinal direction. The radial and azimuthal directions are determined with respect to the axis A.

[0039] The control unit 10 includes a plurality of vanes 12 pivotally mounted on a stator 14 . The pivot axis B of each blade 12 is oriented in a radial direction. Each blade 12 is mounted on the stator 14 by a pivot-only connection 23 (ie pivot connection) in which the only movement (or degree of freedom) allowed is a rotational movement about the axis B.

[0040] Each blade 12 is connected to a control ring 16 by a connecting rod. Each rigid link 18 connects the blade 12 to the control ring 16 by a ball jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com