Surface layer structure for combined transformer shell and surface layer processing method thereof

A combined transformer and surface structure technology, applied in the transformer/inductor casing, substation/distribution device casing, etc., can solve the problem of incompatibility between the appearance of the combined transformer and the surrounding environment, and ensure the service life and sun protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

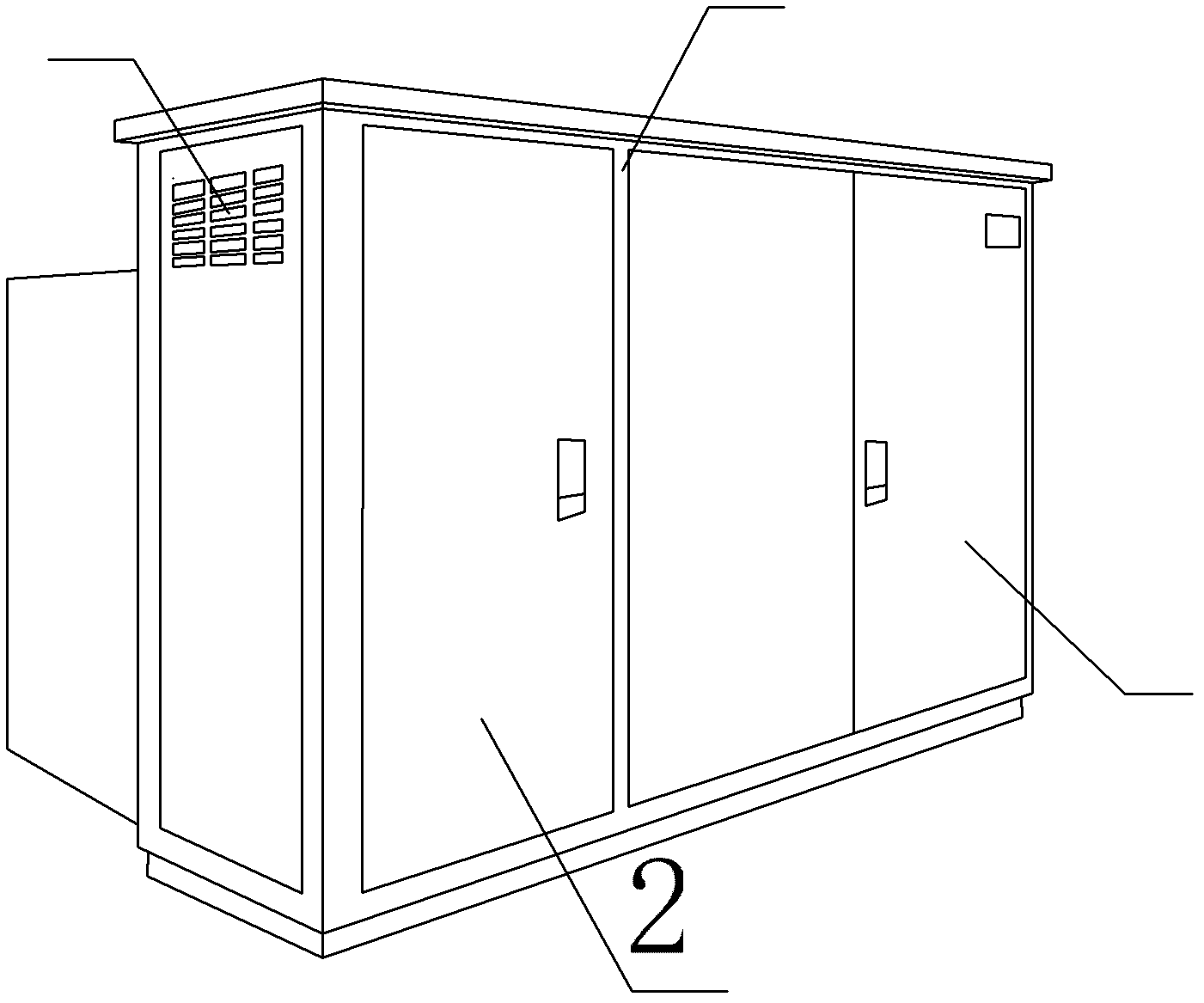

[0010] see figure 1 , one of the present invention, a surface structure of a combined transformer shell, the transformer shell is provided with a door frame 1, a heat dissipation louver 2, and a high-voltage chamber door 3, a low-voltage chamber door 4, combined with the door frame 1, heat dissipation The position of the louver 2 on the transformer shell is that on the high-voltage chamber door 3, the low-voltage chamber door 4, and the side walls of the shell, there is a spray coating conforming to the pattern of the combined transformer installation environment as a whole, and on the spray coating It is covered with a layer of protective varnish that acts as sun protection, rain protection and corrosion protection.

[0011] The second aspect of the present invention is a surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com