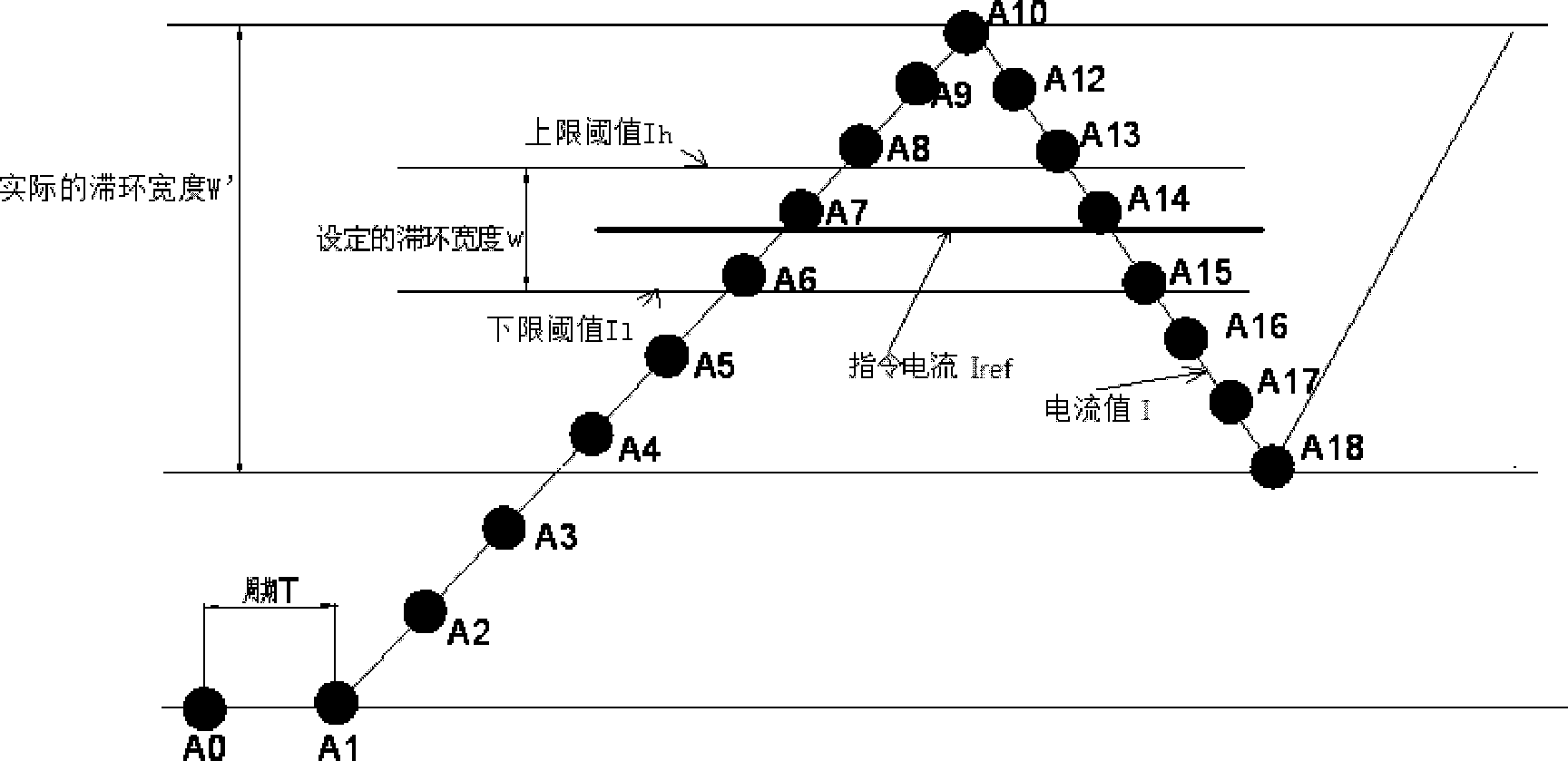

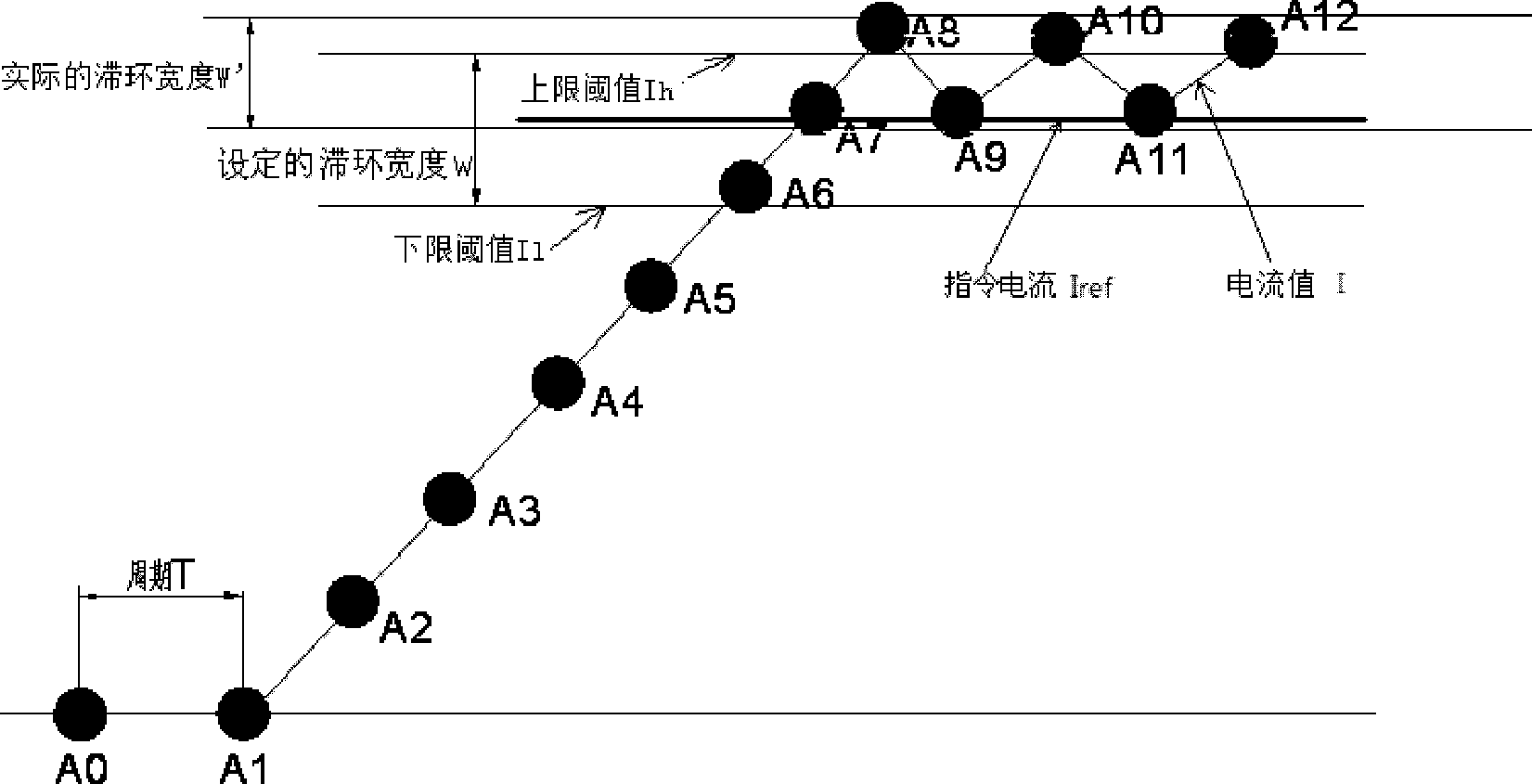

Hysteresis comparison control method

A control method and hysteresis comparison technology, which is applied in the direction of control/regulation systems, instruments, and electric variable adjustments, can solve problems such as the increase of hysteresis width, and achieve the reduction of hysteresis width, filter amplitude, and filter cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0017] Preferably, it can be judged whether the current is in a rising phase or a falling phase by setting the flag bit FLAG of the current value I. Therefore, according to a preferred embodiment, the judging step further includes: judging whether the current is in the rising phase or the falling phase according to the flag bit FLAG of the current value I, and if the flag bit FLAG is the first value, judging that the current is in the rising phase , if the flag bit FLAG is the second value, it is judged that the current is in the falling phase; the step of adjusting the rising current further includes: if the current is increased, the flag bit FLAG of the current value I is updated to the first value, and if the current is decreased, Then the flag bit FLAG of the current value I is updated to a second value; the step of adjusting the falling current further includes: if the current is increased, the flag bit FLAG of the current value I is updated to the first value, and if the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com