Alarm device for embroidery machine

An alarm device, embroidery machine technology, applied in embroidery machines, embroidery machine mechanisms, auxiliary devices, etc., can solve the problems of cumbersome installation process, high cost, circuit short circuit, etc., to achieve a guaranteed alarm effect, guaranteed accuracy, Overcoming the effect of breakable springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

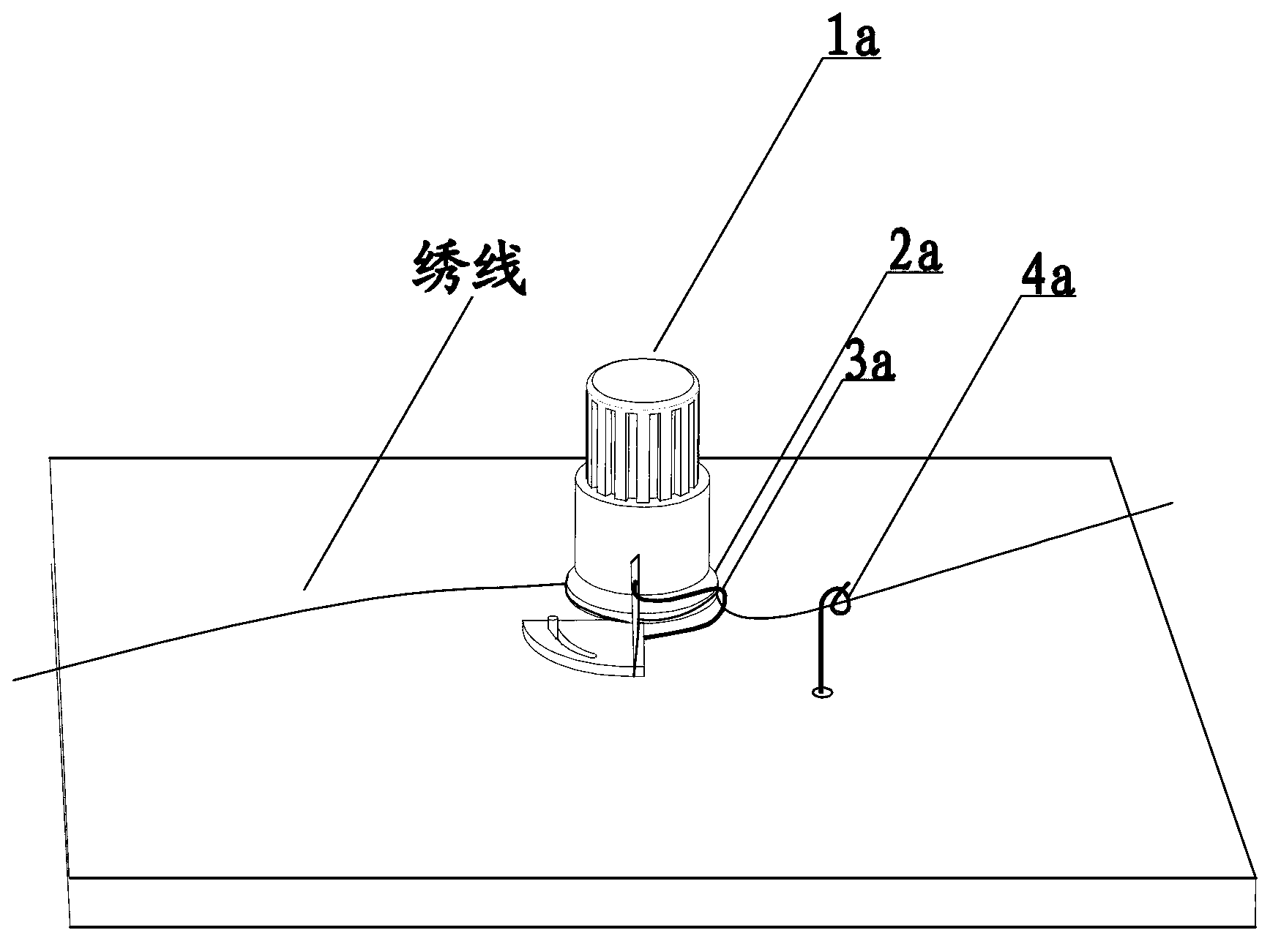

Embodiment 1

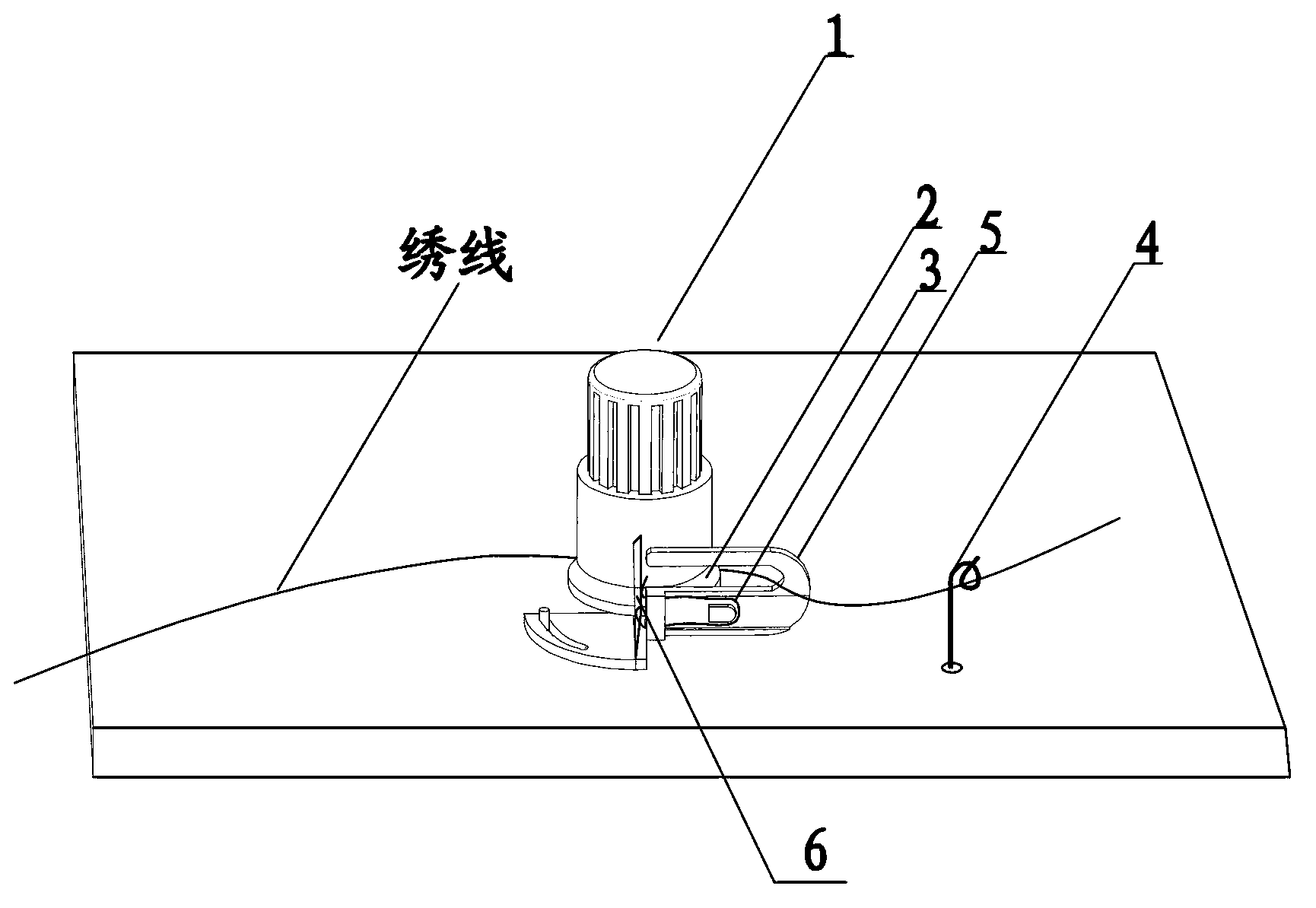

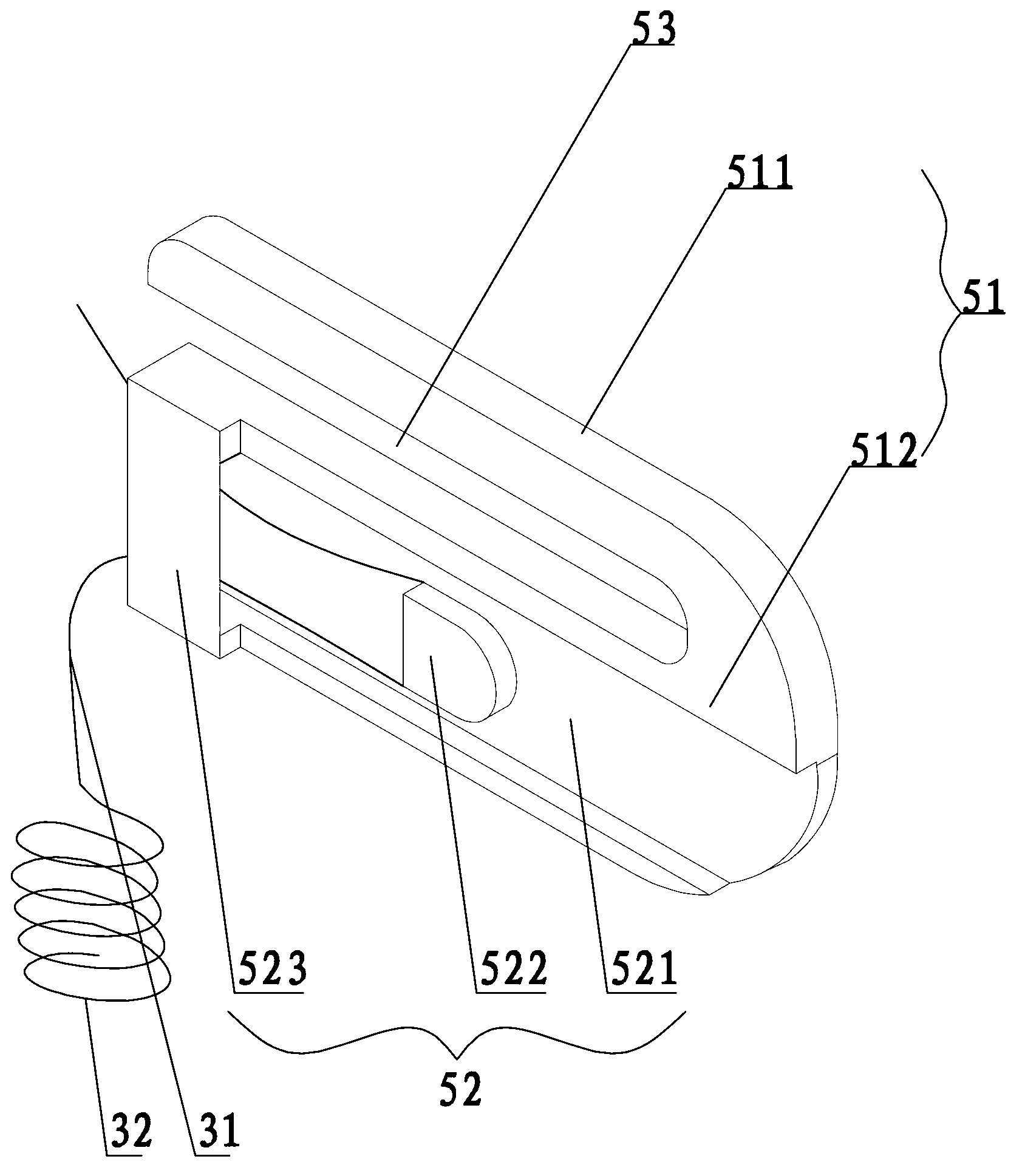

[0024] The embroidery alarm device of the present invention combines figure 2 , Including the thread passing wheel 1, the wheel seat 2 and the alarm component 5. The thread passing wheel 1 is installed on the wheel seat 2. The alarm component 5 includes a hook structure 51, a fixing structure 52 and a thread groove 53, as well as an alarm contact spring 3 and The sensing sheet 6 used in conjunction with the alarm contact spring 3, the hook structure 51 is divided into a hook portion 511 and a body 512. The gap between the hook portion 511 and the body 512 forms a wire slot 53; the fixing structure 52 is arranged on the body 512; The bottom end 32 of the contact spring is fixed under the wire passing wheel 1, and the upper end 31 of the alarm contact spring is matched and installed on the fixing structure 52 for fixing the alarm component 5. image 3 , The fixing structure 52 includes a groove 521 opened along the body 512 of the hook structure 51, a hanging spring buckle 522 arr...

Embodiment 2

[0027] The configuration and working principle of this embodiment are the same as that of the first embodiment. The difference is that the alarm component 5 includes a hook structure 51, a fixing structure 52, and a wire-passing groove 53. The hook structure 51 is divided into a hook 511 and a body 512. Figure 4 , The fixing structure 52 includes a groove 521, an anti-drop opening 523, and a hanging spring buckle 522 arranged in the groove 521. The fixing structure 52 is arranged on the side of the main body 512, and the groove 521 is perpendicular to the plane where the main body 512 and the hook 511 are located. The upper end 31 of the spring penetrates into the through groove 521 through the anti-drop opening 523, and is positioned by the hanging spring buckle 522. The groove 521 is a through groove, and the alarm component 5 is made of glass as a whole.

[0028] The use of different structures of the alarm component 5 can realize different installation methods, so that the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com