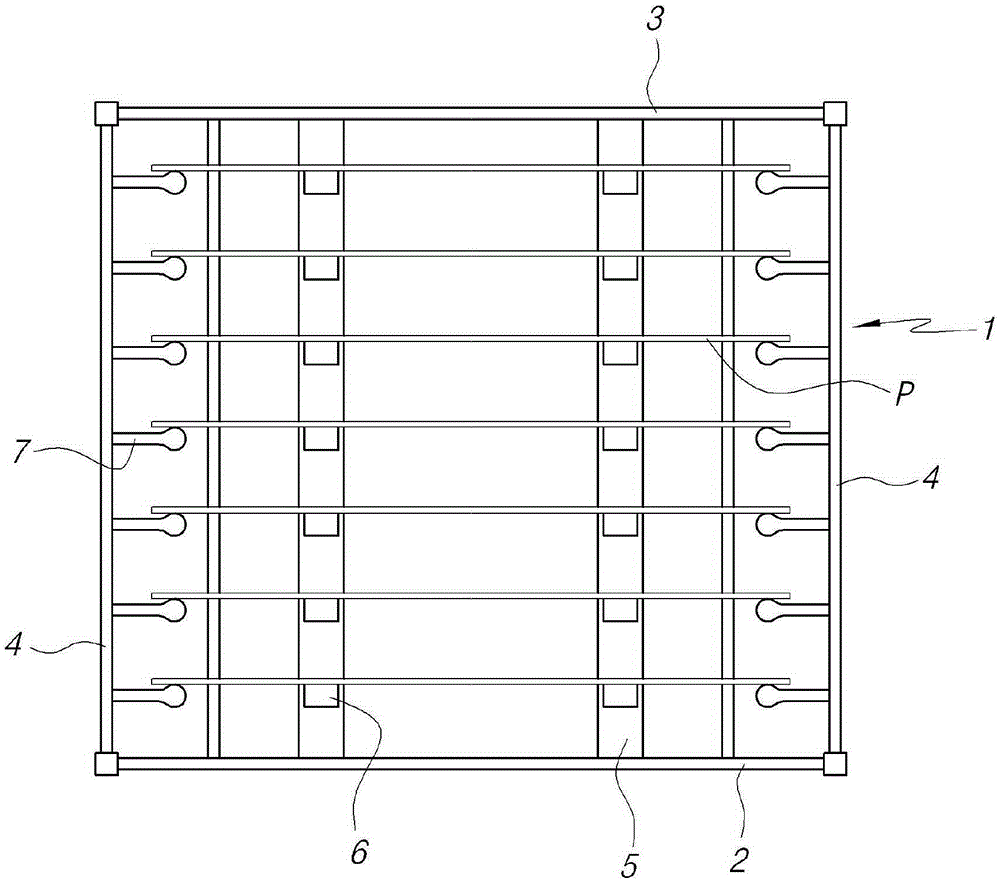

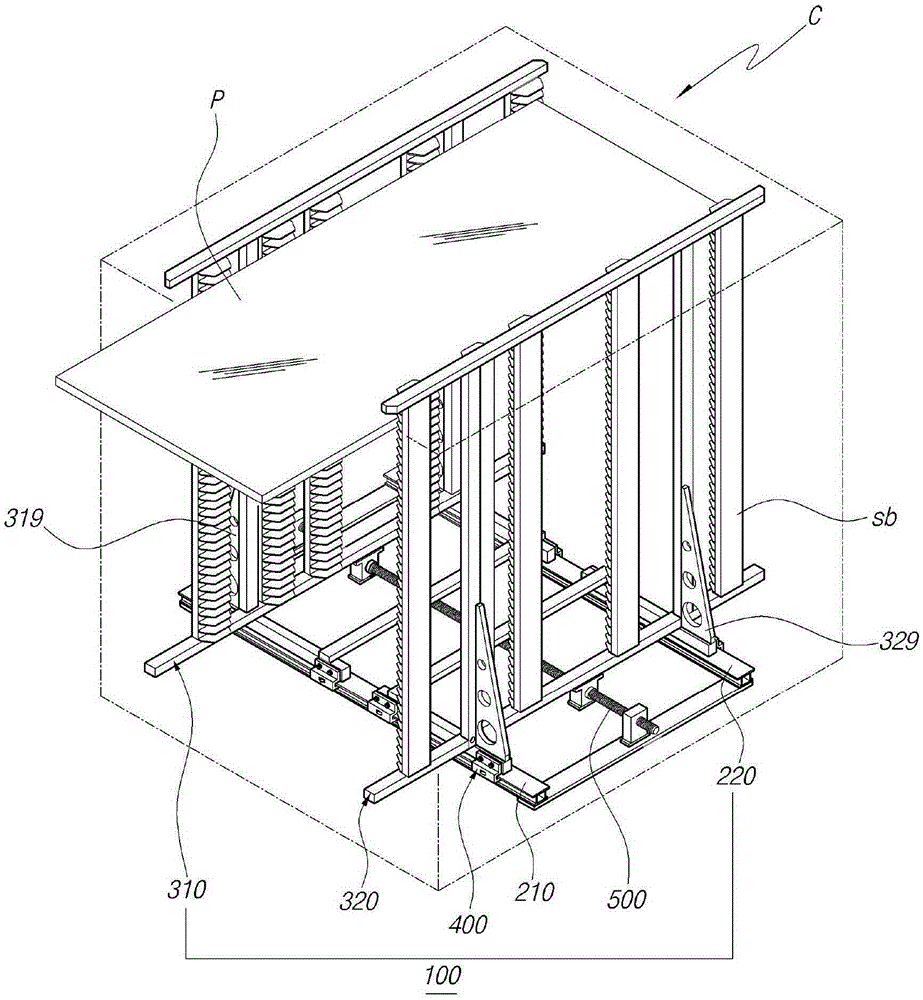

Glass substrate loading cassette with adjustable spacing between slot bars

A glass substrate, adjustable technology, applied in the direction of packaging, transportation and packaging, packaging of vulnerable items, etc., can solve the problems of difficult to do the correct installation, the length of the long hole is not too long, and the process is cumbersome, so as to improve the accuracy and Speed, improved convenience, and wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention are described below.

[0055] The described embodiments are only intended to enable those skilled in the art to easily understand the technical ideas of the present invention, and do not limit the present invention. The embodiments of the present invention can be modified into other implementations within the technical idea and scope of the present invention. "And / or" used in this specification means including at least one of the constituent elements listed before and after. The term "on" other components in this specification means that other components are directly located on a certain component, and also includes that there may be a third component on the certain component. In this specification, terms such as "first" and "second" are used to refer to each member or part, but these are expressions used for clarity of description, and do not limit each member or part. The thicknesses and relative thicknesses of the components shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com