Adjustable non-support windshield wiper structure

A non-bracket type, wiper technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of heavy overall weight, unfavorable market competitiveness, and increased overall cost of non-bracket type wipers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

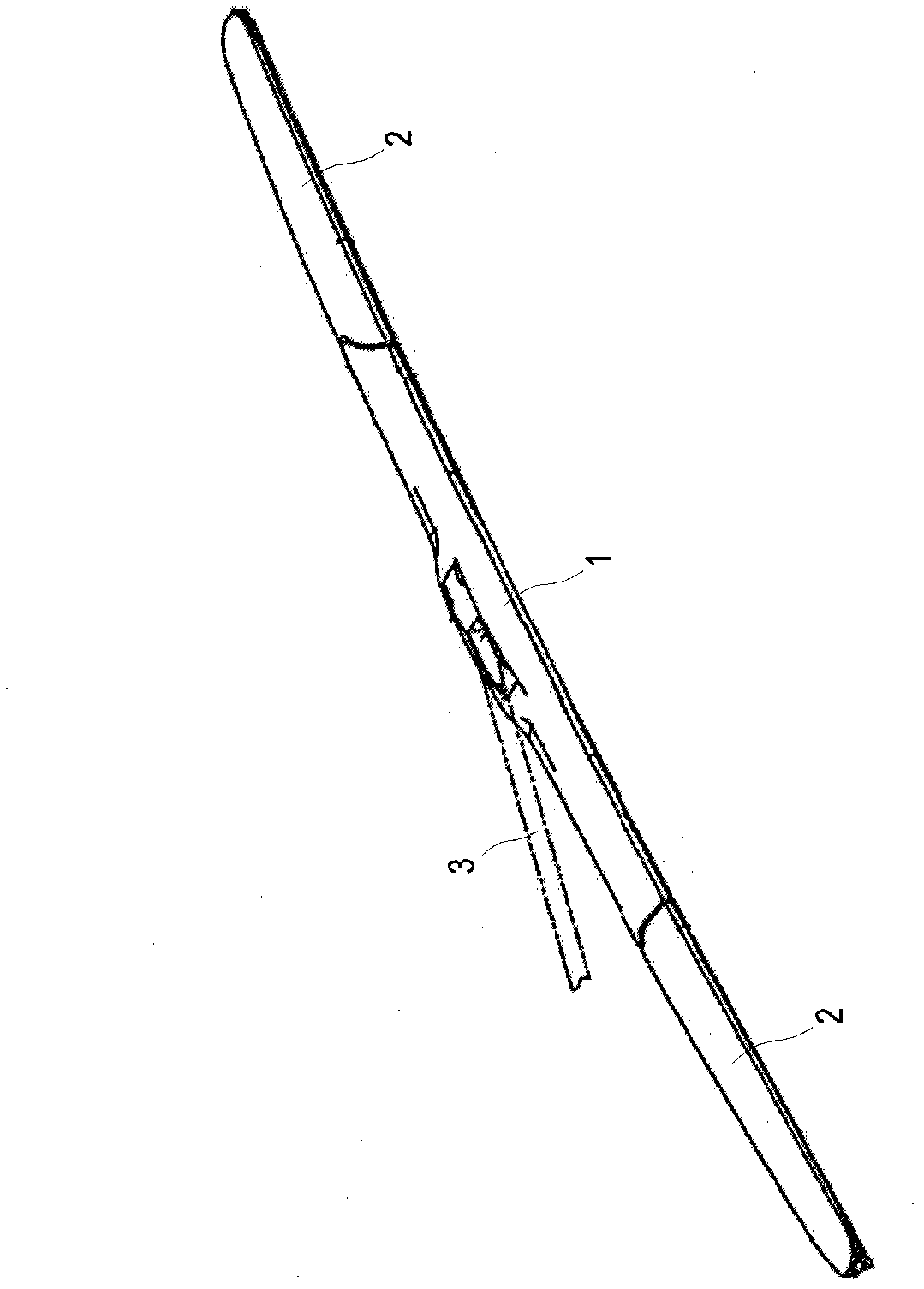

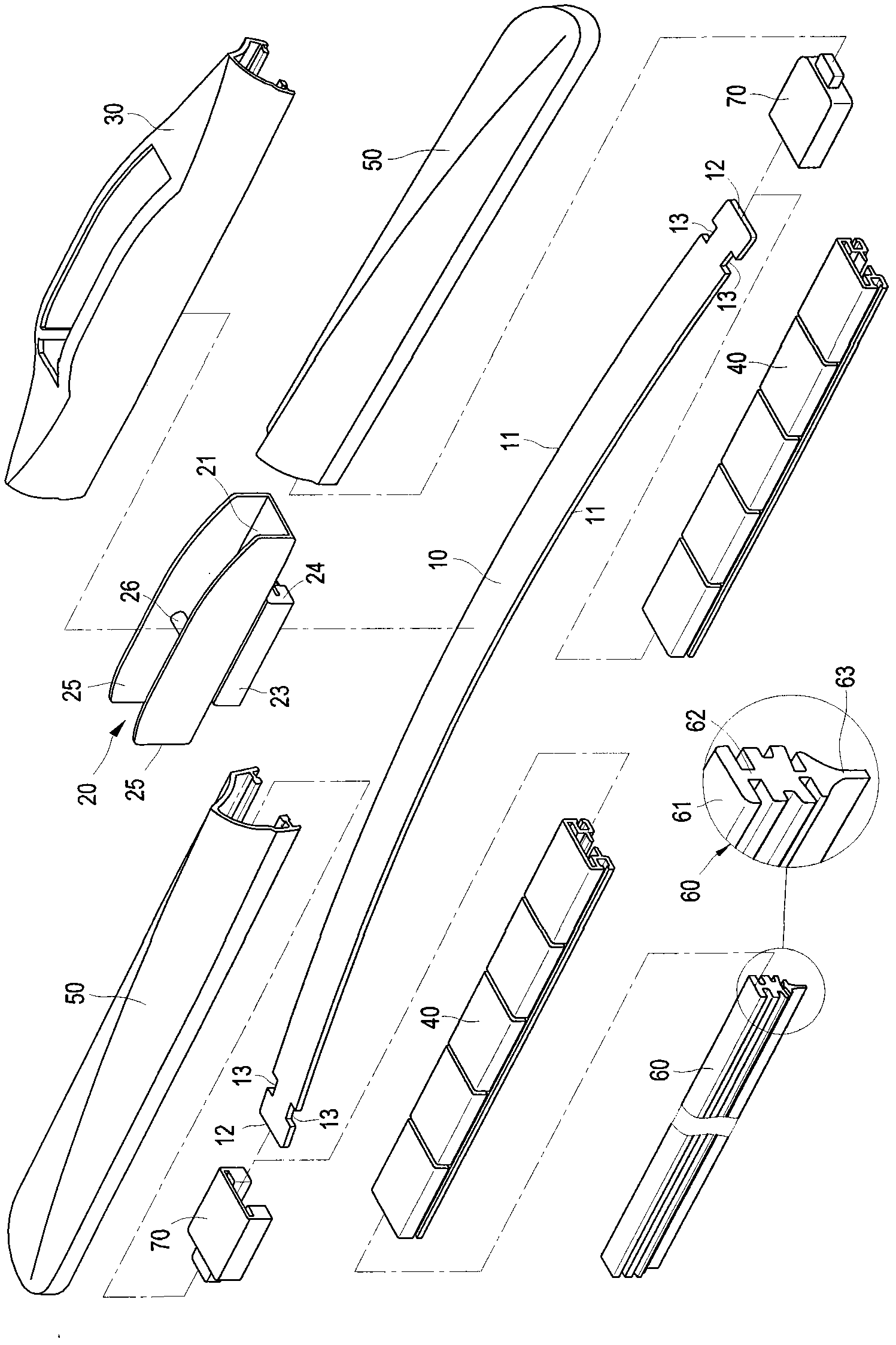

[0081] Such as Figure 2 to Figure 19 and Figure 29 to Figure 36 As shown, the adjustable non-support type wiper structure of the present invention includes:

[0082] The metal dome body 10 is made of a flexible metal material and is a flat rectangular strip that bends downwards. It has a rectangular section and two long sides 11 and two short sides 12 parallel to each other. The two sides near the two short sides 12 On each long side 11, each concave is provided with a pair of symmetrical and inward grooves 13;

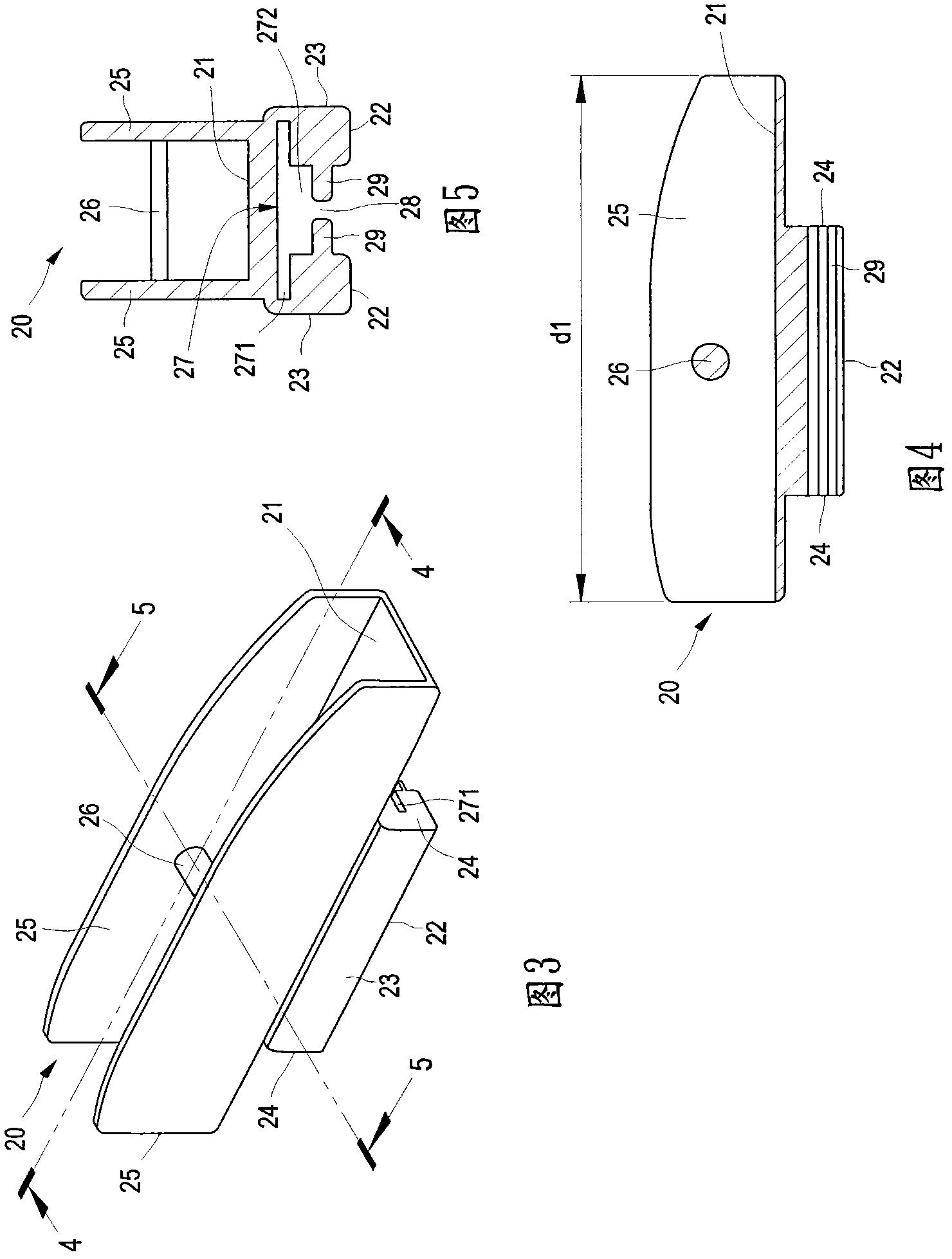

[0083] The receiving seat 20 is slipped on the central position of the metal dome body 10 , and is a cuboid integrally injection-molded from plastic material, having a top surface 21 , a bottom surface 22 , two long sides 23 and two short sides 24 . The top surface 21 protrudes upwards with two vertical surfaces 25 parallel to each other, and a support shaft 26 is straddled between the two vertical surfaces 25, which can be connected and fixed on the wiper after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com