Movable joint mechanism for mechanical arm

A technology of movable joints and robotic arms, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of easy failure of the movable joint mechanism of the mechanical arm, and achieve the effect of easy assembly, not easy to fail, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

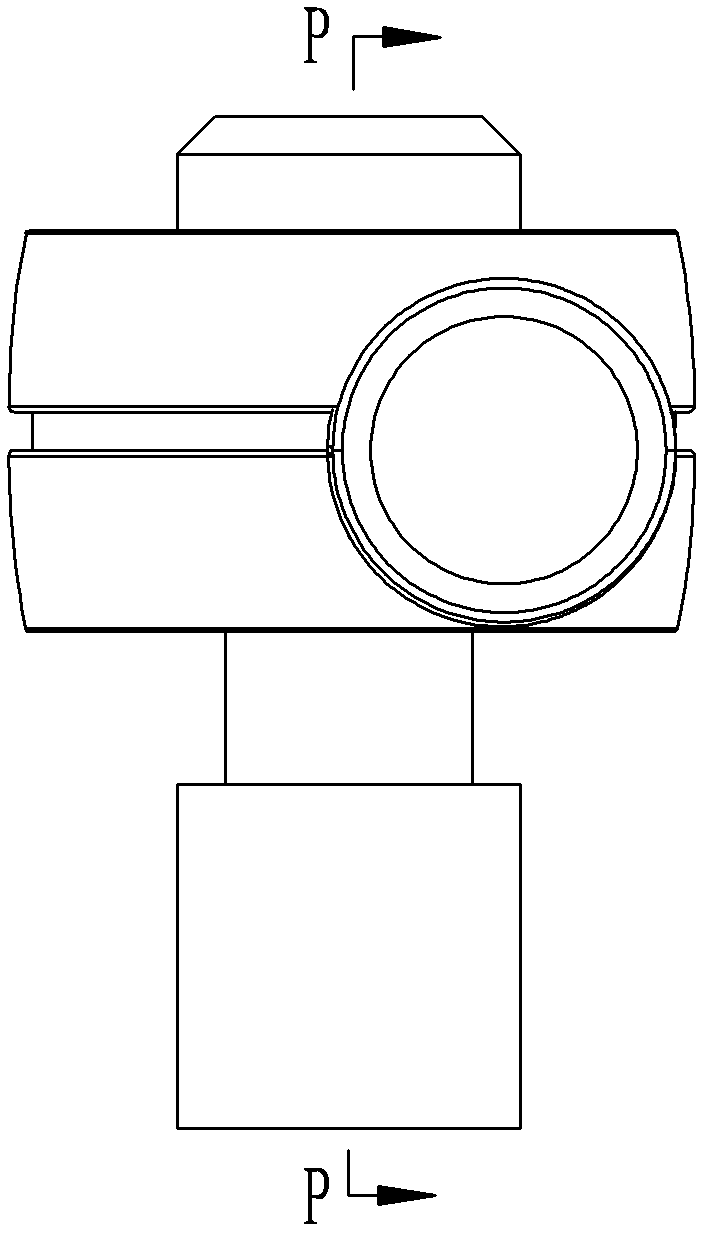

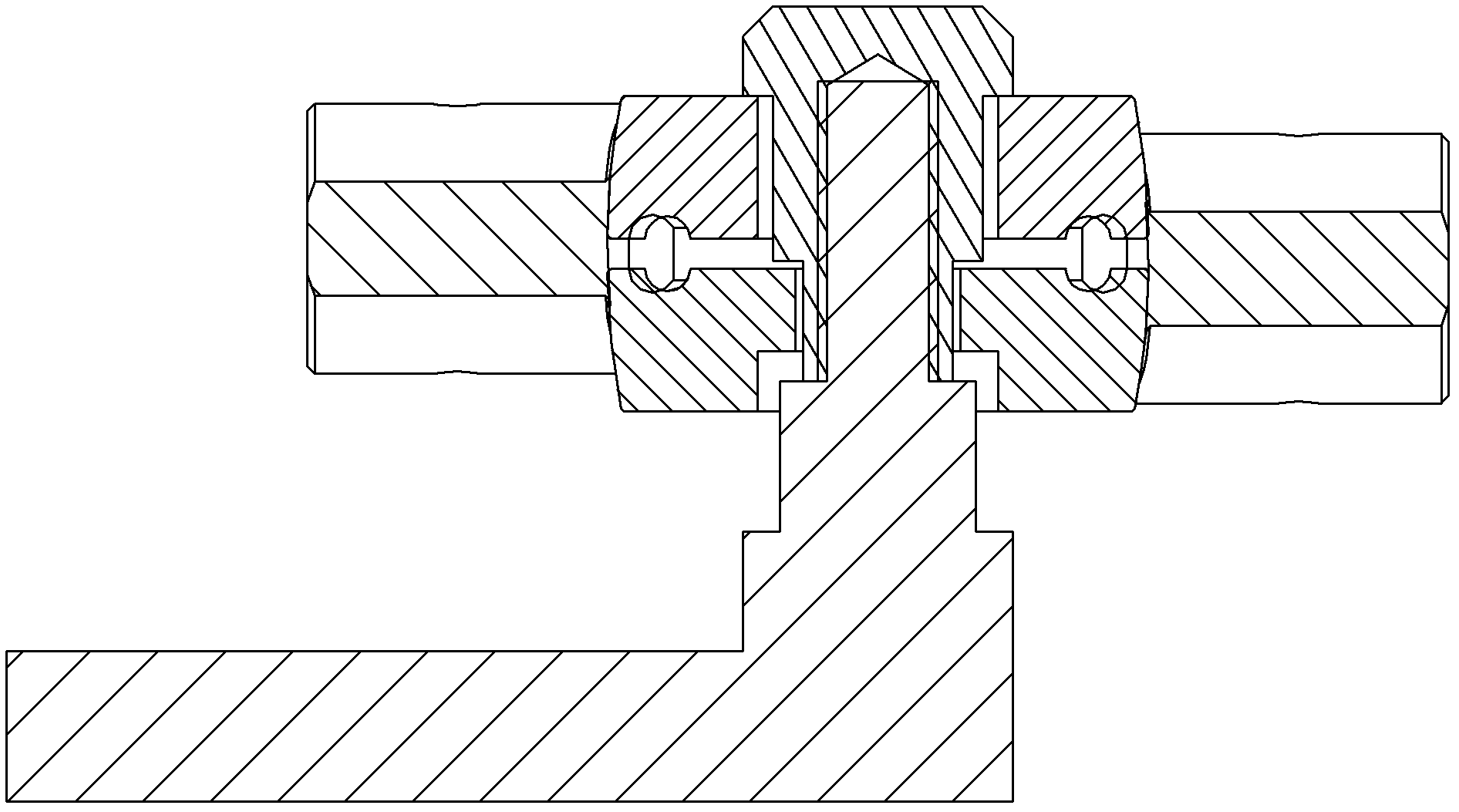

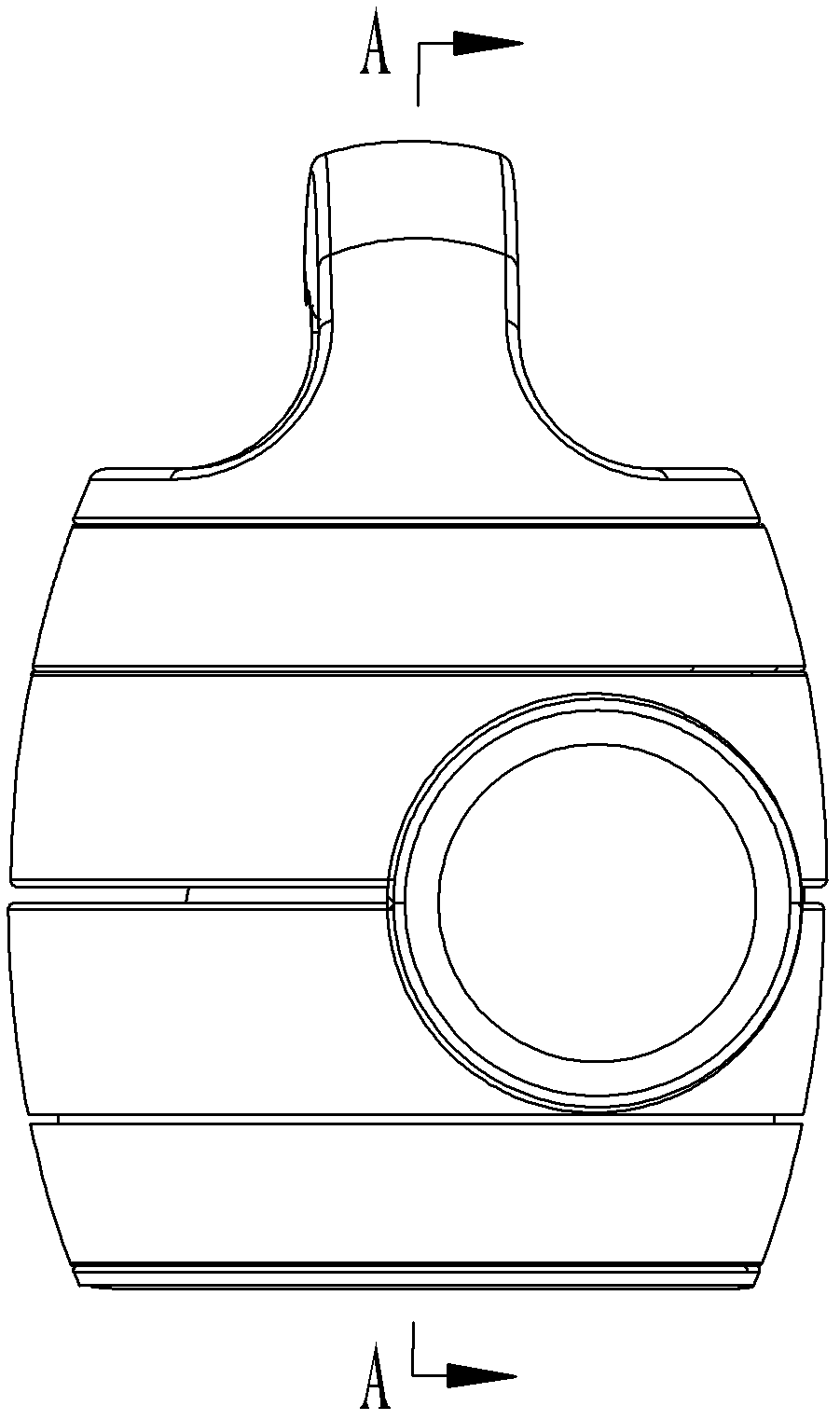

[0020] Such as Figure 3-5 As shown, the movable joint mechanism of the mechanical arm in this embodiment includes a first rotary buckle 1 and a second rotary buckle 2, and the first rotary buckle 1 and the second rotary buckle 2 are buckled by a tapered surface in the axial direction, and The degree of tightness of the fastening is adjusted through the threaded connection structure. A gap is left between the ends of the conical surfaces, and the first rotary buckle 1 and the second rotary buckle 2 are provided with connecting parts for connecting the mechanical arms on their respective revolving surfaces that are not the conical surfaces.

[0021] The connecting part is in the shape of a cylinder, and a connecting part installation hole penetrating through the cylinder is arranged radially on it, and the connecting part is used for fixedly connecting the mechanical arm with the connecting part.

[0022] The threaded connection structure is a threaded hole opened in the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com