Constant-temperature greenhouse

A constant temperature and constant temperature layer technology, applied in the field of agricultural greenhouses, can solve problems such as unsatisfactory economic benefits, supplementation, and insufficient fresh air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

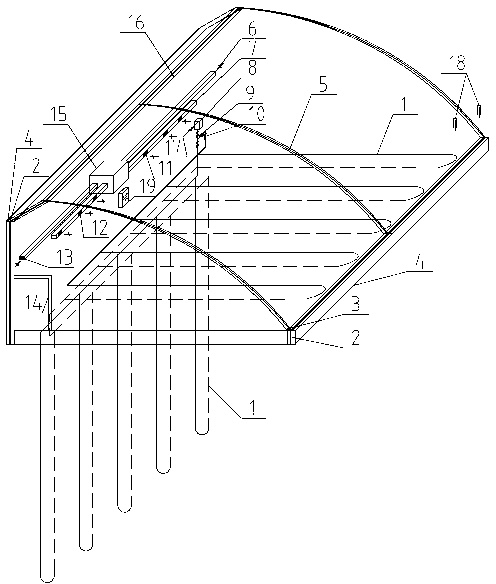

[0013] Now, embodiments of the present disclosure will be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals designate like elements throughout.

[0014] Such as figure 1 is a diagram showing the configuration of a thermostatic booth according to an embodiment of the present disclosure.

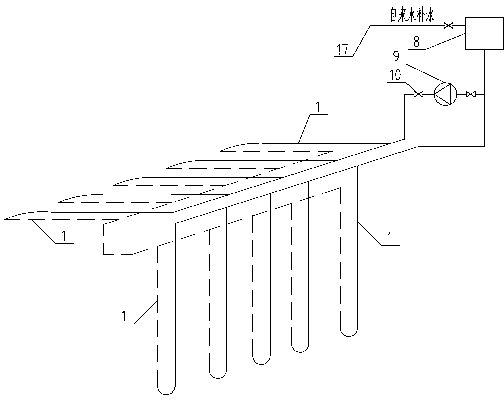

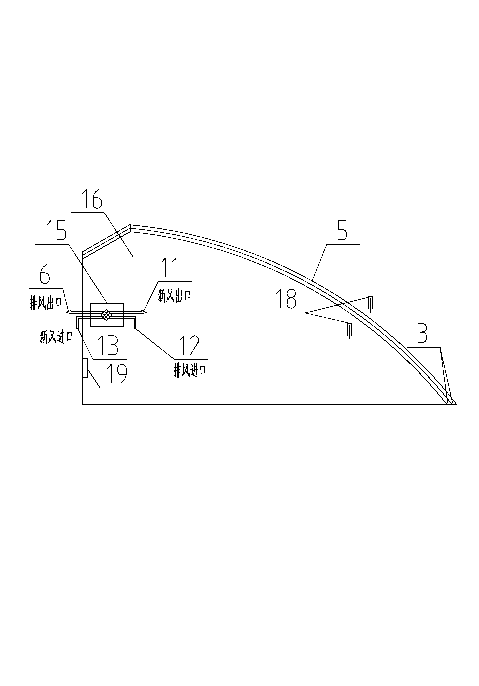

[0015] Such as figure 1 As shown, the schematic diagram of the structure of the constant temperature shed; including: PE heat exchange tube 1; water tank 8, used to replenish water in the PE heat exchange tube 1; water pump 9, used to promote the water circulation in the PE heat exchange tube 1, and the underground The energy of the constant temperature layer is brought to the shallow ground to maintain the constant temperature of the ground; the fresh air ventilator 15 is used to supplement the fresh air in the constant temperature shed, recycle the energy in the constant temperature shed, and maintain the environment needed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com