On-load capacity-adjusting switch high voltage primary loop structure

A primary circuit, capacity adjustment switch technology, applied in the direction of circuits, transformers, variable transformers, etc., can solve problems such as difficult to achieve arc extinguishing, and achieve the effect of saving installation steps, saving costs, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

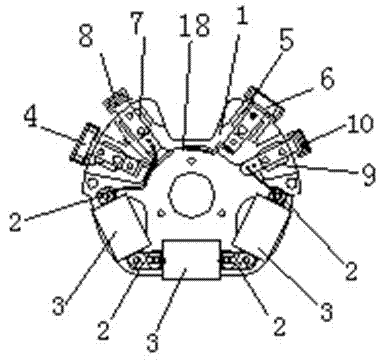

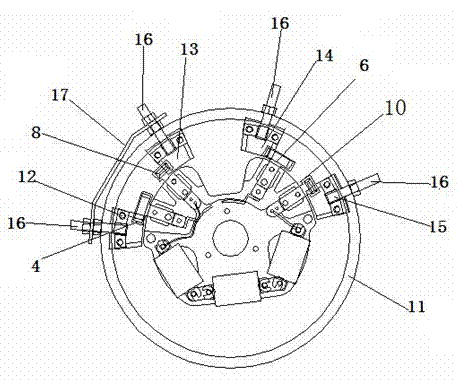

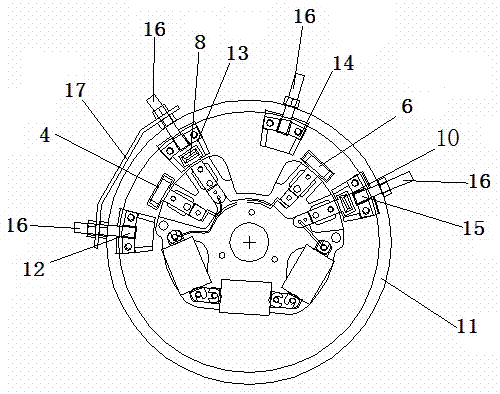

[0016] like figure 1 As shown, a high-voltage primary circuit structure of an on-load capacity regulating switch, which includes: an insulating plate (1), three resistors (3) fixed on the insulating plate (1) and connected in series through a resistor insert (2), through The first main contact (4) fixed on the insulating disk (1) by the first contact insert (3), the second main contact fixed on the insulating disk (1) by the second contact insert (5) The head (6), the first transition contact (8) fixed on the insulating disc (1) through the first arcing contact insert (7), and the first transition contact (8) fixed on the insulating disc (1) through the second arcing contact insert (9) 1) The second transition contact (10), the first static contact (12), the second static contact (13), the third static contact (14) and The fourth static contact (15), the first static contact (12), the second static contact (13), the third static contact (14) and the fourth static contact (15)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com