Optical fiber temperature sensor

A temperature sensor and optical fiber technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of insulated stress, etc., and achieve the effects of simple structure, increased service life, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

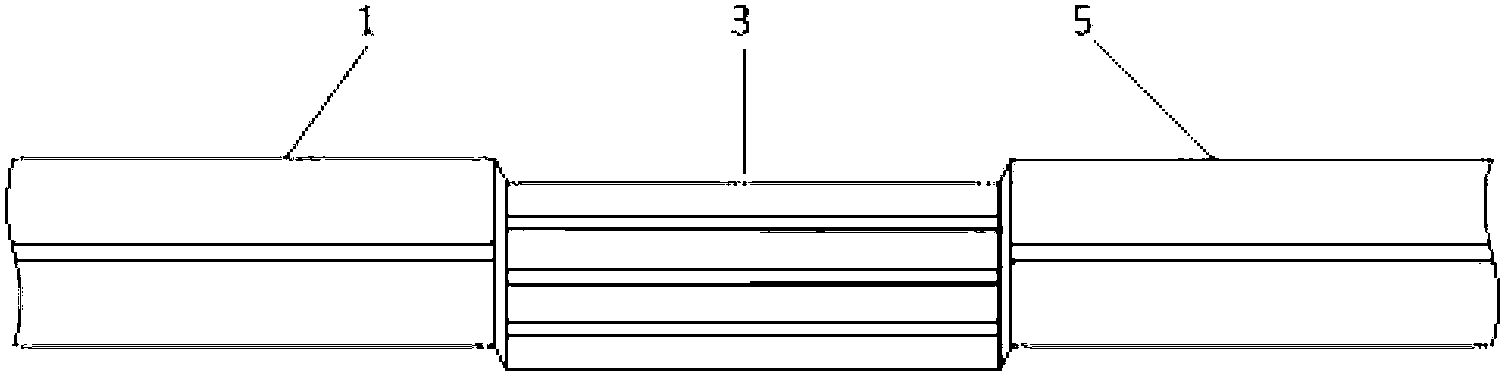

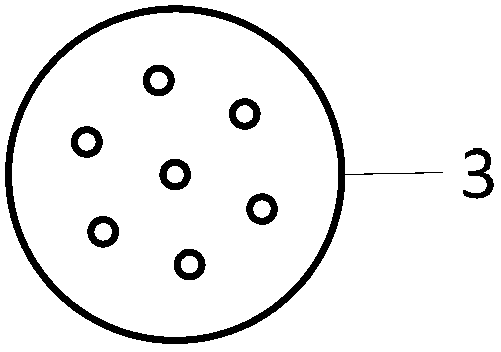

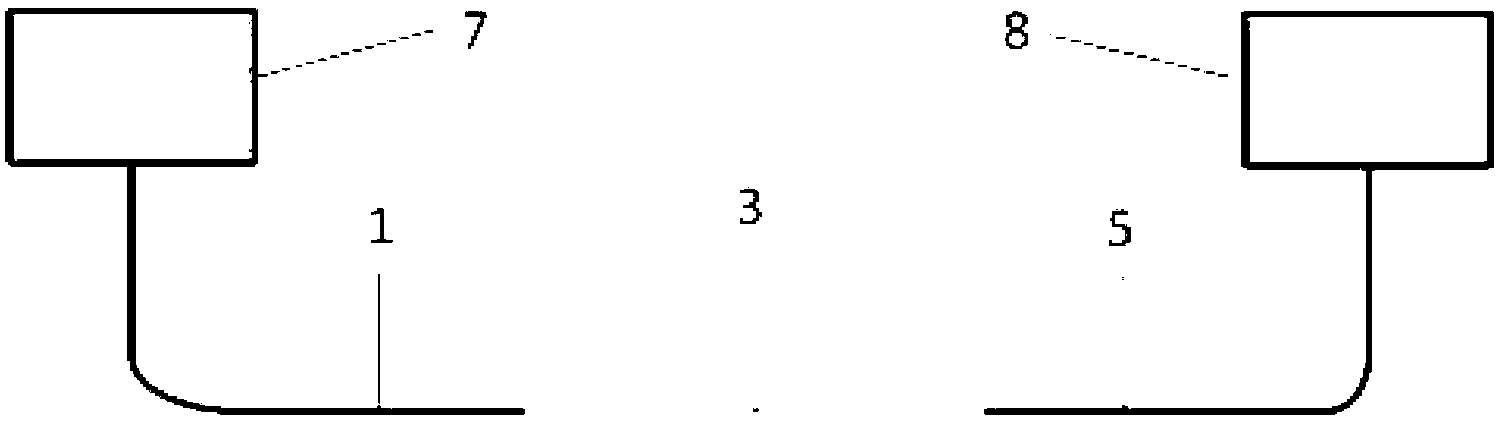

[0016] see Figure 1-Figure 3 , an embodiment of the present invention provides an optical fiber temperature sensor, including a broadband light source 7, a first single-mode optical fiber 1, a second single-mode optical fiber 5, a multi-core optical fiber 3 and an optical analysis device (a spectrometer 8 is used in this embodiment) . The broadband light source 7 is connected to an optical analysis device (a spectrometer 8 in this embodiment) through the first single-mode optical fiber 1 , the multi-core optical fiber 3 and the second single-mode optical fiber 5 in sequence. The joints of the first single-mode optical fiber 1, the second single-mode optical fiber 5 and the multi-core optical fiber 3 are all collapsed structures formed by arc discharge with approximately uniform distribution of the optical fiber refractive index profile. The collapsed structure here refers to the destruction of the step optical fiber The well-defined structure of the core and cladding refract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com