Parameter-varying load optimization control method of thermal power generating unit

A technology of load optimization control and thermal power unit, which is applied to mechanical equipment, engine components, engine starting, etc., can solve the problems of poor load control accuracy, large fluctuation of main parameters, slow load response speed, etc., to ensure the adjustment rate. , Elimination of dead zone and inertia, the effect of logic structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

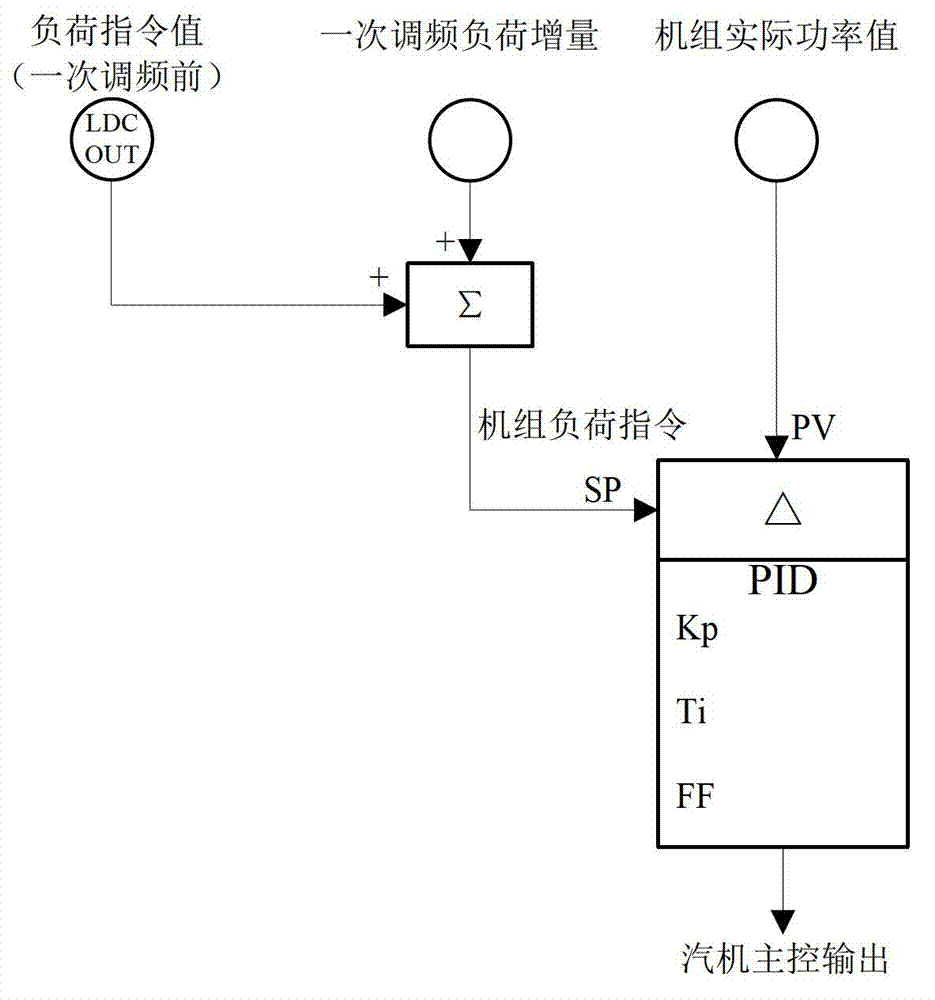

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] Such as Figure 4 As shown, it is applied in a 300MW subcritical, intermediate reheating, and condensing coal-fired unit.

[0033] (1) Put the inertial time constant in the inertial link (LAG), the reference value of the inertial time constant is 10-15s, the load command value and the load command value adjusted by the first-order inertial link are sent to the adder module Σ, In the adder module Σ, adjust the magnitude of the load command value and the load command value adjusted by the first-order inertia link, or introduce a proportional link after the adder module to adjust the load command value and the load command value after the first-order inertia link adjustment. Adjust the amplitude of the load command value difference, and the amplitude adjustment and direction of the two input quantities should be consistent;

[0034] (2) Set the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com