Technology for molding coke breeze or pulverized coal

A technology for pulverized coal and pulverized coke, applied in the field of powder forming technology, can solve the problems of unusable pulverized coke agglomerates, narrow application range, high requirements, etc., to reduce equipment costs and energy costs, control molding costs, Make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

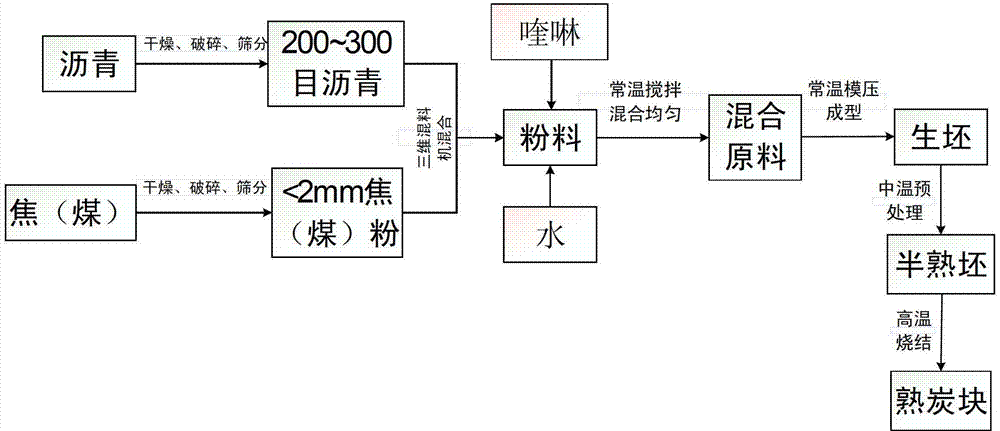

Method used

Image

Examples

Embodiment 1

[0039] 1) Weigh 100g powder coke (<1mm) and 10g asphalt (0.48mm~0.75mm), and use a three-dimensional mixer to mix well at room temperature to obtain a powder. Use a measuring cylinder to measure 2mL of quinoline and 12mL of water, quinoline and water are slowly added to the powder at the same time, and fully stirred at room temperature for 10 minutes until the mixture is uniform, and the raw material is obtained.

[0040] 2) Press the mixed raw materials with a hydraulic press at 15.92MPa, hold the pressure for 5s, and make a green body with a cylinder size of about d:2cm×h:5cm, which has good strength.

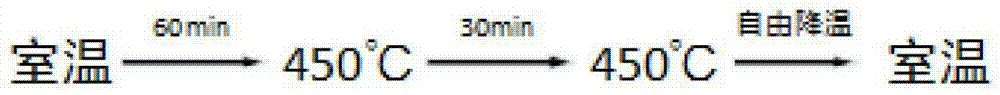

[0041] 3) Put the green body in a 450°C resistance furnace for medium temperature treatment. The specific temperature rise curve is:

[0042]

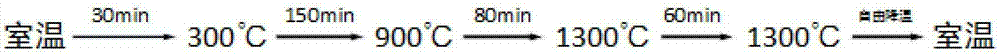

[0043] 4) Put the green body in a 1300°C resistance furnace for high-temperature sintering treatment. The specific heating curve is:

[0044]

[0045] 5) The prepared charcoal block has a compressive strength of 6.04MPa and a t...

Embodiment 2

[0047] 1) Weigh 100g powder coke (<1mm) and 10g asphalt (0.48mm~0.75mm), and use a three-dimensional mixer to mix them evenly at room temperature to obtain a powder. Use a measuring cylinder to measure 5mL of quinoline and 12mL of Water, quinoline and water are slowly added to the powder at the same time, and fully stirred at room temperature for 10 minutes until the mixture is uniform, and the raw material is obtained.

[0048] 2) Press the mixed raw materials with a hydraulic press at 15.92MPa, hold the pressure for 5s, and make a green body with a cylinder size of about d:2cm×h:5cm, which has good strength.

[0049] 3) Put the green body in a 450°C resistance furnace for medium temperature treatment. The specific temperature rise curve is:

[0050]

[0051] 4) Put the green body in a 1300°C resistance furnace for high-temperature sintering treatment. The specific heating curve is:

[0052]

[0053] 5) The prepared cooked carbon block has a compressive strength of 3.7...

Embodiment 3

[0055] 1) Weigh 100g of pulverized coal (<1mm) and 10g of asphalt (0.48mm~0.75mm), and use a three-dimensional mixer to mix them well at room temperature to obtain a powder. Measure 4mL of quinoline and 12mL of Water, quinoline and water are slowly added to the powder at the same time, and fully stirred at room temperature for 10 minutes until the mixture is uniform, and the raw material is obtained.

[0056] 2) Press the mixed raw materials with a hydraulic press at 9.55MPa, hold the pressure for 5s, and make a green body with a cylinder size of about d:2cm×h:5cm, which has good strength.

[0057] 3) Put the green body in a 450°C resistance furnace for medium temperature treatment. The specific temperature rise curve is:

[0058]

[0059] 4) Put the green body in a 1200°C resistance furnace for high-temperature sintering treatment. The specific heating curve is:

[0060]

[0061] 5) The prepared charcoal block has a compressive strength of 3.58MPa and a true density of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com