Hinge assembly of flat-top tower crane

A tower crane, articulated technology, applied in the direction of cranes, etc., to achieve the effect of simple manufacture, compact layout, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

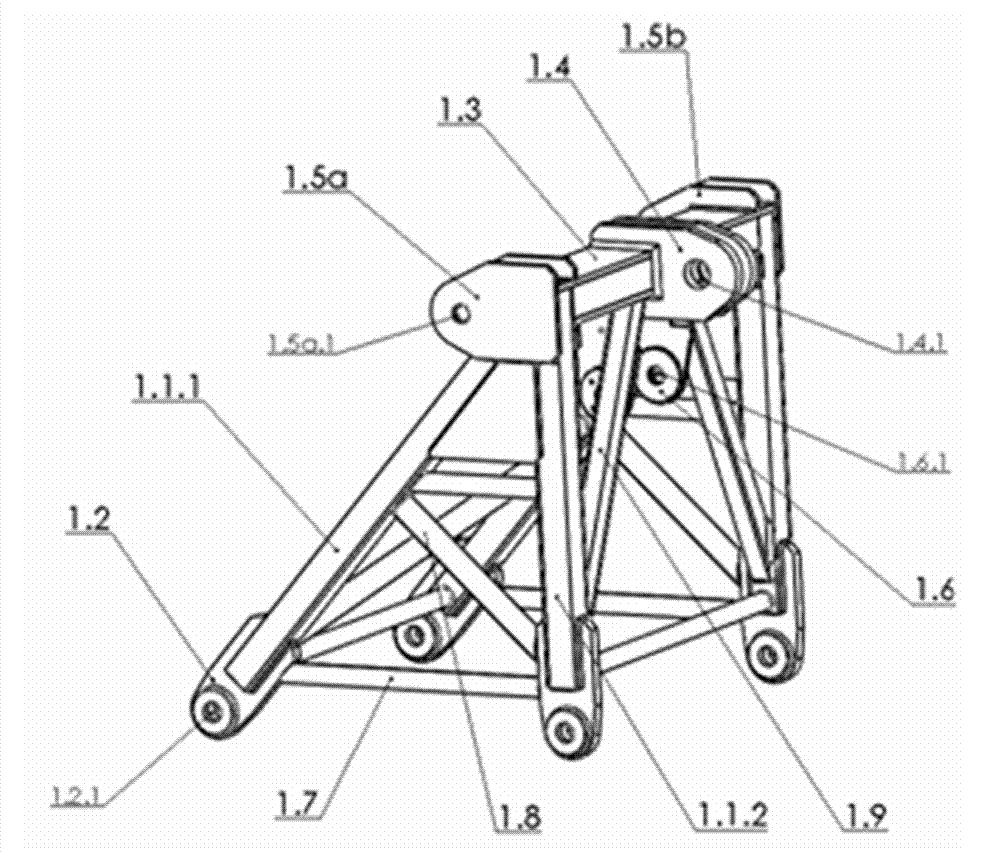

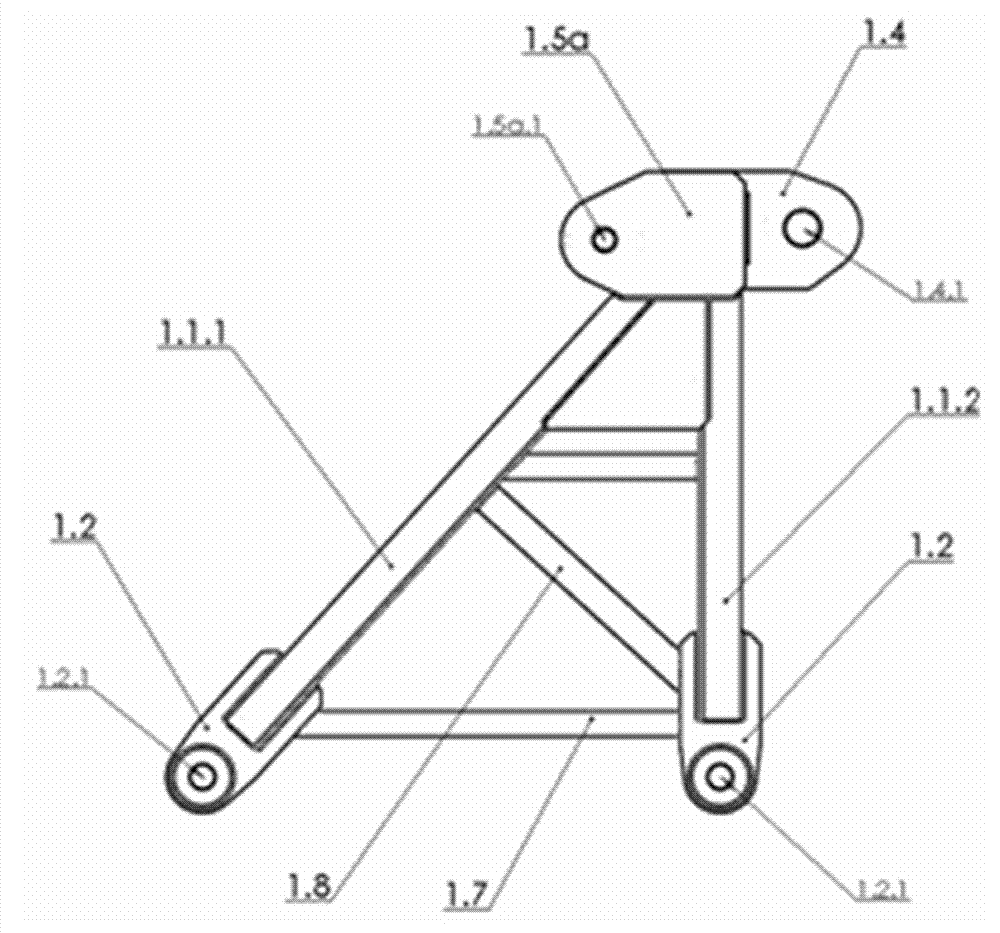

[0025] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , A flat-top tower crane articulation device, the present invention is composed of the main steel structure 1 and the transition joint 2, wherein: the main steel structure includes the main chord 1.1, the slewing connecting ear plate 1.2, the beam 1.3, the transition joint connecting ear plate 1.4. Balance arm tie rod connecting ear plate 1.5, ear plate 1.6 for installing rope pulley, bottom connecting rod 1.7, web rod 1.8, reinforcing rod 1.9;

[0026] The transition section 2 is a double-hammer structure, and the two hammers are respectively provided with shaft pin holes 2.1 and boom pin holes 2.2;

[0027] The connecting structure of the main steel structure 1 is the inclined main chord 1.1.1 on the rear side and the straight main chord 1.1.2 on the front side. After the inclined main chord and the straight main chord are paired and welded, the upper ends are respectively welded to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com