Satellite type rotating cold ironing device and cold ironing printing method

A printing method and cold stamping technology, applied in rotary printing machines, transfer printing, printing, etc., can solve the problems of unstable pulling and influence of main printing materials, strict requirements for tension control of printing materials, and unstable overprinting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

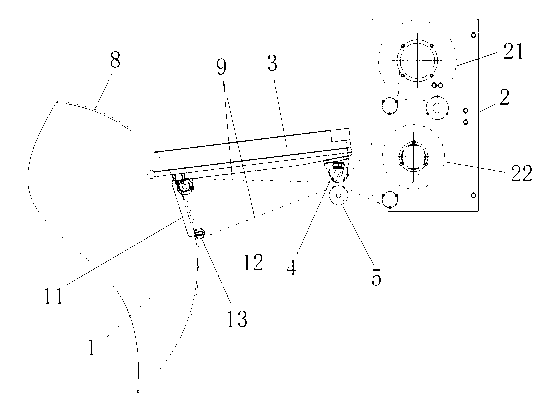

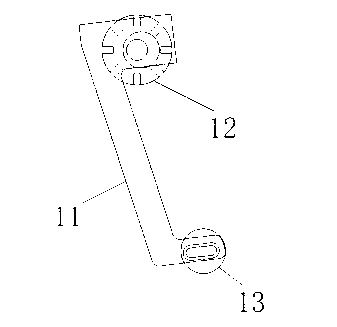

[0013] see figure 1 and figure 2 , the satellite type rotary cold ironing device of the present invention includes a bottom printing wheel 1, and the main printing material 8 rotates along the bottom printing wheel 1, as figure 1 shown by the dotted line in . A connection block 11 is arranged on the edge of one side of the bottom printing wheel 1 , and a rotatable compound wheel 12 and a separation wheel 13 are respectively fixed at both ends of the connection block 11 . The composite wheel 12 and the separating wheel 13 support the main printing material 11 on the bottom printing wheel 1 .

[0014] The cold ironing device also includes a cold ironing supply shaft 21 and a cold ironing paper recovery shaft 22, which are respectively fixed in a cold ironing carton 2. Frozen paper 9 is introduced into compound wheel 12 from said cold perm supply shaft 21, and is compounded with main printing material 8 on the bottom printing wheel 1;

[0015] The present invention uses comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com