Lifting type layered oil production tubular column

A layered oil recovery, lifting technology, applied in the direction of drill pipe, casing, production fluid, etc., can solve the problems that affect the oil recovery rate, the improvement of oilfield development benefits, interlayer interference, and prominent interlayer contradictions, etc., and achieve significant technical effects and economic benefits, reduce the number of operations, and save operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

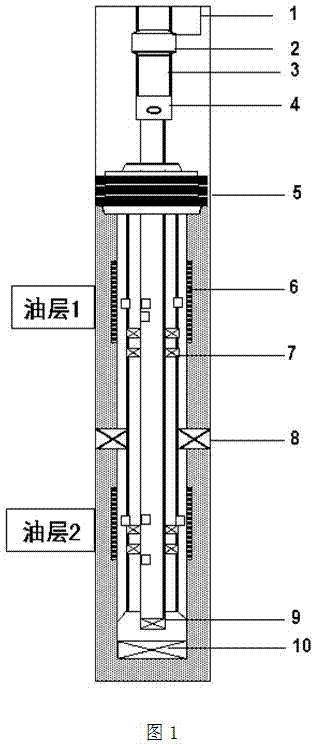

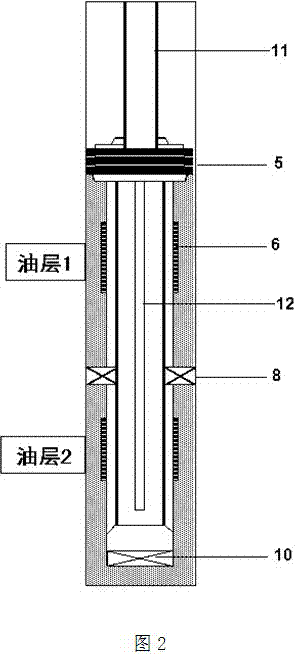

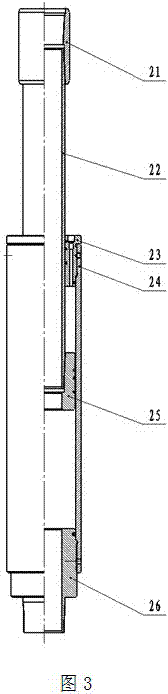

[0018] As shown in the drawings, a lift-type layered oil production string is composed of a production string and a hand-off string. The production string includes a hydraulic control pipeline 1, a hydraulic lifting device 2, a production tubing 3, an oil well pump 4, Seal plug 7 and guide screw plug 9. connected from top to bottom. The lost-hand string is composed of a hanging packer 5 , a double-layer sand filter pipe 6 , a layered packer 8 and a bottom plug 10 . The double-layer sand filter pipe 6 is set outside the sealing plug and is located in the oil layer at the lower end of the hanging packer 5, the hanging packer is set at the upper end of the sealing plug below the oil well pump, and the layered packer 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com