Industrialization production technology for extracting ginkgolic acid from Ginkgo testa

A technology of ginkgo outer seed coat and production technology, which is applied in the field of industrialized production technology and extraction of ginkgolic acid, can solve the problems of complicated and cumbersome extraction process, inability to popularize and apply, and high operation requirements, and achieves simple process, improved utilization value, and killing effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

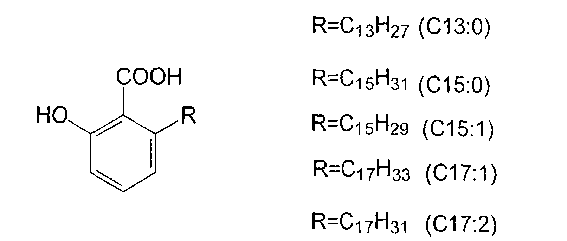

Image

Examples

Embodiment 1

[0028] A kind of industrialized production technology of extracting ginkgolic acid from the outer testa of ginkgo, is characterized in that comprising the following steps:

[0029] (1) Grind the washed ginkgo testa until fine, pass through 30 mesh, add water 5 times its weight, stir and soak for 5 hours;

[0030] (2) Centrifuge the soaked mixed solution to remove slag, pump the filtrate into the concentration pot, fractionate the components at 48°C under a vacuum of 0.08Mpa, and concentrate them;

[0031] (3) Add 10% hydrochloric acid to the concentrated solution to adjust the pH value to 3, cool to 10°C, brown crystals are precipitated, and 60% ginkgolic acid is obtained by suction filtration;

[0032] (4) After fully dissolving the brown crystals in step (3) with ethanol at 50°C, filter out the insoluble matter, cool to 20°C, precipitate light brown crystals, and filter to obtain 90% ginkgolic acid;

[0033] (5) Add the light brown crystals in step (4) to 5 times the weight...

Embodiment 2

[0036] A kind of industrialized production technology of extracting ginkgolic acid from the outer testa of ginkgo, is characterized in that comprising the following steps:

[0037] (1) Grind the washed ginkgo testa until fine, pass through 60 mesh, add water with 8 times the weight, stir and soak for 8 hours;

[0038] (2) Centrifuge the soaked mixed solution to remove slag, pump the filtrate into the concentration pot, fractionate the components at 60°C under a vacuum of 0.085Mpa, and concentrate them;

[0039] (3) Add 20% hydrochloric acid to the concentrated solution to adjust the pH value to 2.5, cool to 2°C, brown crystals are precipitated, and 65% ginkgolic acid is obtained by suction filtration;

[0040] (4) After fully dissolving the brown crystals in step (3) with ethanol at 60°C, filter out the insoluble matter, cool to 13°C, precipitate light brown crystals, and filter to obtain 93% ginkgolic acid;

[0041] (5) Add the light brown crystals of step (4) into water wit...

Embodiment 3

[0044] A kind of industrialized production technology of extracting ginkgolic acid from the outer testa of ginkgo, is characterized in that comprising the following steps:

[0045] (1) Grind the washed ginkgo testa until fine, pass through 80 mesh, add water 10 times the weight, stir and soak for 12 hours;

[0046] (2) Centrifuge the soaked mixed solution to remove slag, pump the filtrate into the concentration pot, fractionate the components at 70°C under a vacuum of 0.09Mpa, and concentrate them;

[0047] (3) Add 30% hydrochloric acid to the concentrated solution to adjust the pH value to 2, cool to -5°C, brown crystals are precipitated, and 70% ginkgolic acid is obtained by suction filtration;

[0048] (4) After fully dissolving the brown crystals in step (3) with ethanol at 70°C, filter out the insoluble matter, cool to -5°C, precipitate light brown crystals, and filter to obtain 95% ginkgolic acid;

[0049](5) Add the light brown crystals in step (4) to 8 times the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com