Glass base plate load transfer device

A transfer device and glass substrate technology, applied in glass production, glass transportation equipment, glass manufacturing equipment, etc., can solve the problems of inability to meet the needs of mass production, slow speed, and limited quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The detailed content and technical description of the present invention will be further described by examples, but it should be understood that these examples are for illustrative purposes only, and should not be construed as limitations on the implementation of the present invention.

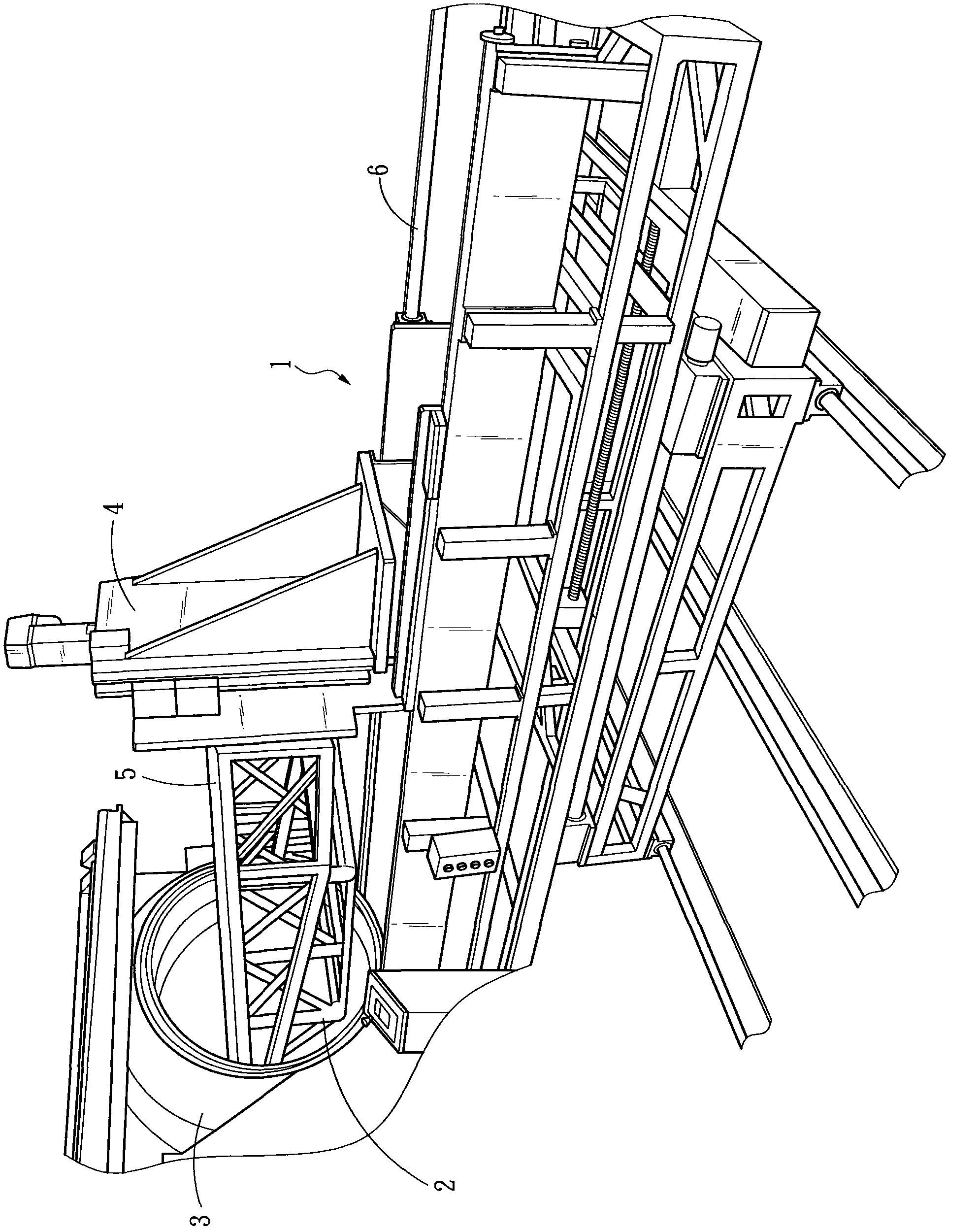

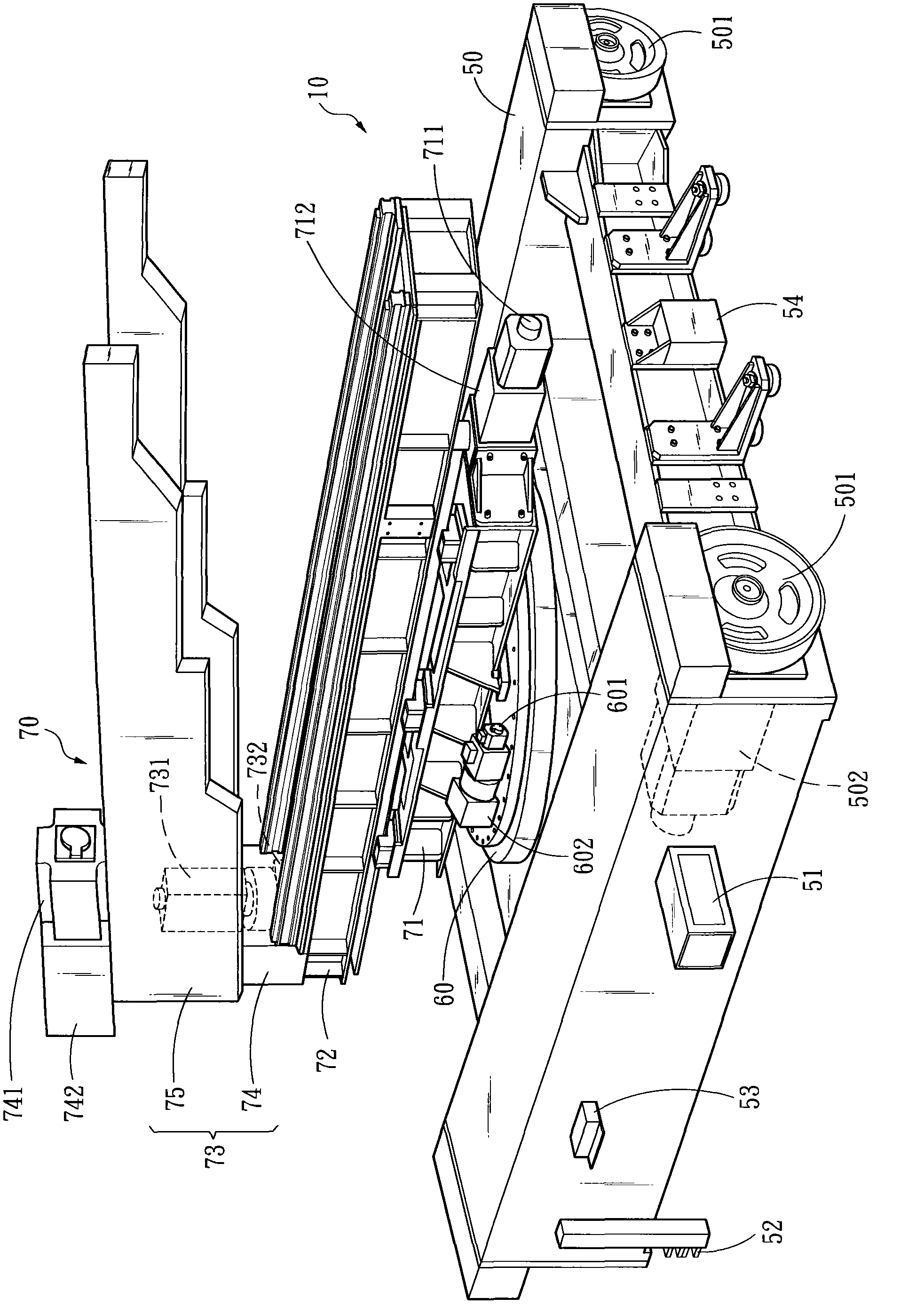

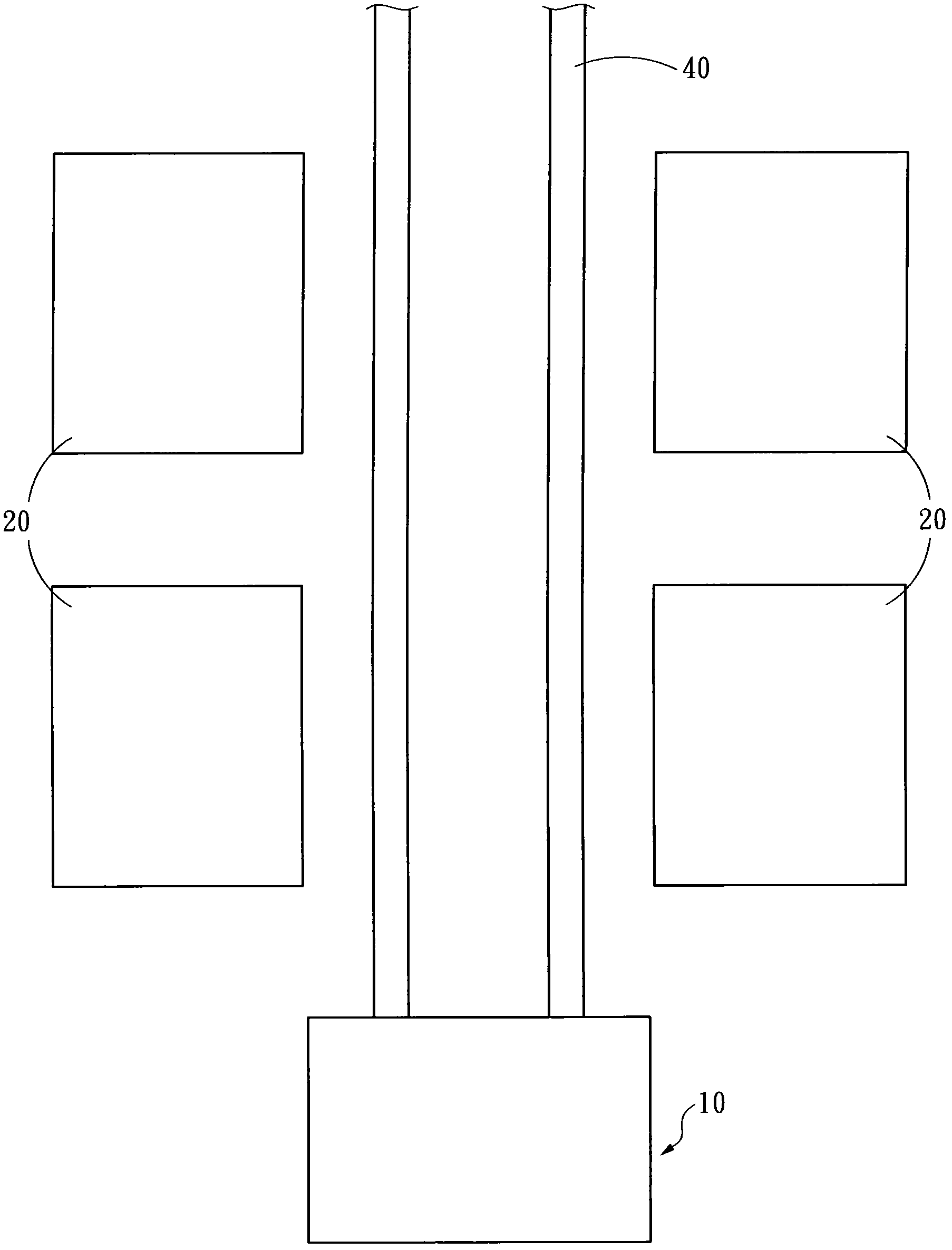

[0017] see figure 2 and image 3 As shown, the present invention is a glass substrate transfer device 10, which is provided in a plurality of reaction furnaces 20, and inserts or takes out a quartz frame 30 (such as Figure 6A shown), which includes a track 40, a trolley 50, a rotating assembly 60, and a telescopic pick-up frame 70, wherein the plurality of reaction furnaces 20 are located on both sides of the track 40, and the plurality of reaction furnaces 20 can be Each accommodates access to a quartz rack 30 .

[0018] The trolley 50 is provided with four track wheels 501, and the four track wheels 501 are arranged on the track 40, and the trolley 50 is provided with a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com