Workpiece fixing mechanism used for riveting pressure assembly machine

A technology for fixing mechanisms and assembling machines, which can be used in workpiece clamping devices, metal processing, manufacturing tools, etc., and can solve problems such as poor positioning accuracy, high labor intensity for operators, and unreliable clamping strikes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

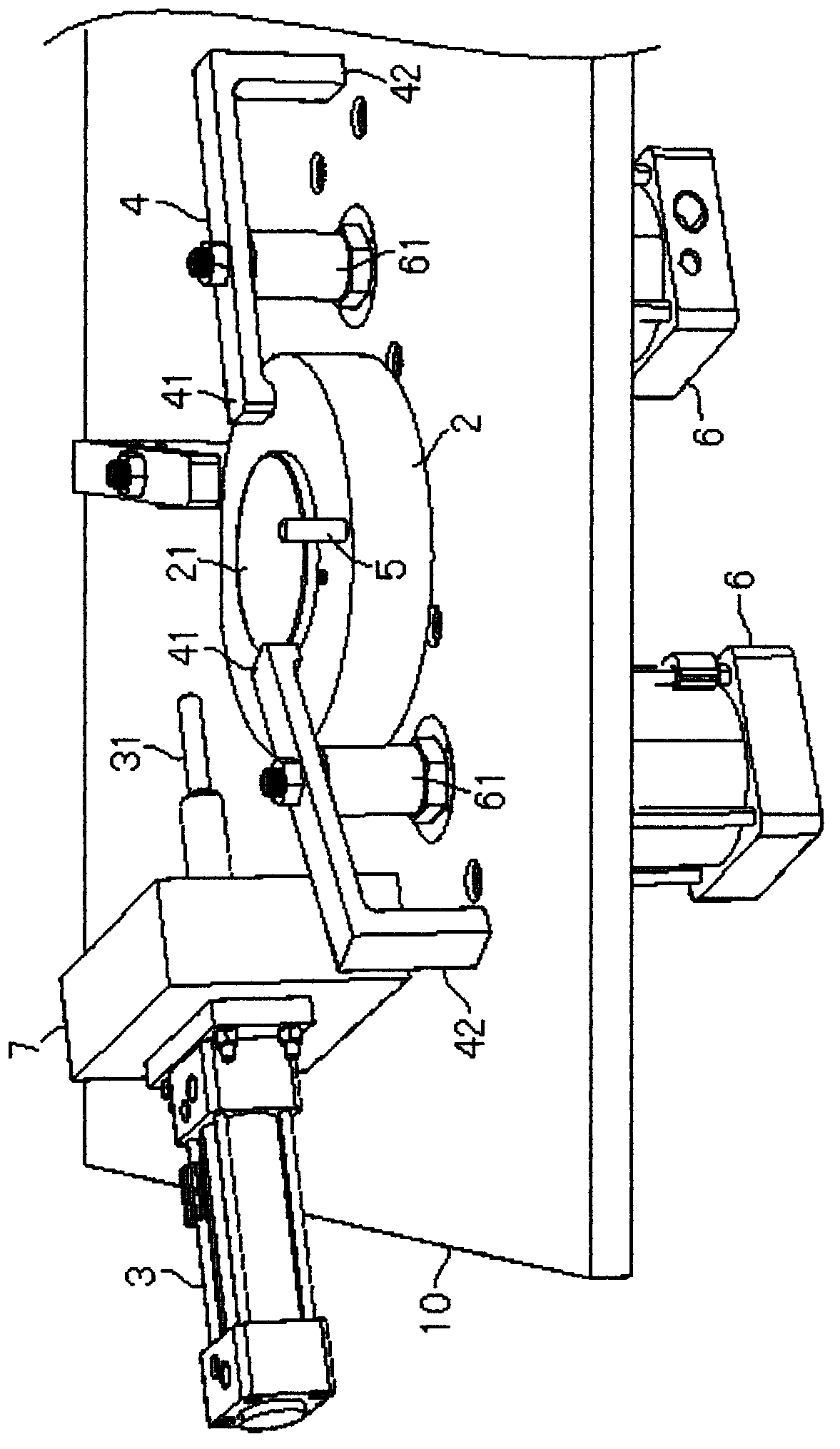

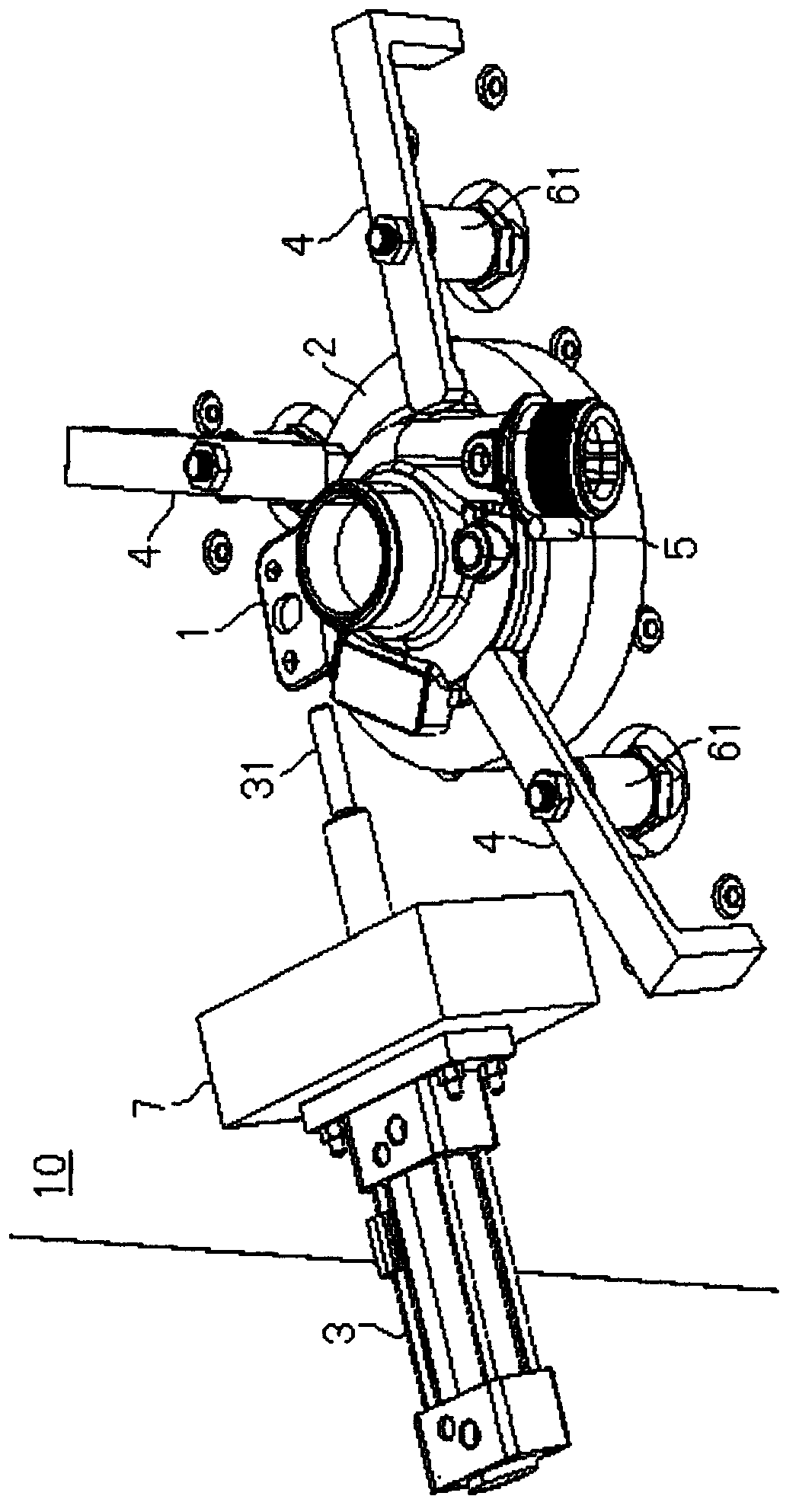

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0023] refer to figure 1 , figure 2 As shown, a workpiece fixing mechanism for a riveting assembly machine is used to fix the housing 1, including a positioning plate 2 fixed above the working plane 10, a side cylinder 3 located on the side of the positioning plate 2 and a positioning plate located on the side of the positioning plate 2. A set of platens 4 above the disc 2. The side top cylinder 3 is fixed on the working plane 10 through the cylinder connecting plate 7 .

[0024] The positioning plate 2 is provided with a cylindrical boss 21 and a positioning pin 5 , and the cylindrical boss 21 corresponds to the bottom hole of the housing 1 .

[0025] The piston movement direction of the side cylinder 3 is parallel to the working plane 10 . A push rod 31 is coaxially connected with the piston of the side jack cylinder 3 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com