Method of assembly and precision calibration of numerical control four-axis ring die deep hole drill machine tool

An assembly method and deep hole drilling technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problem of pellet feed that affects the production cost of feed, is expensive, and affects the service life of ring dies. Issues such as the output of the press machine and the quality of the feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

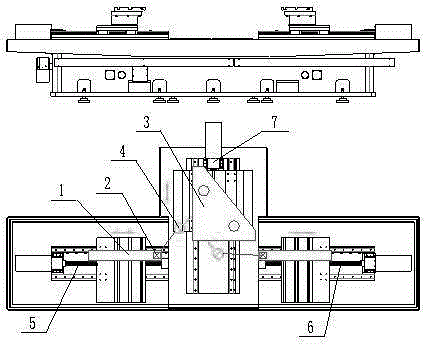

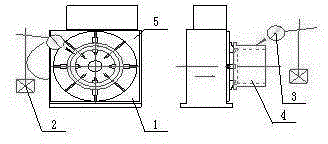

[0014] The structure and specific operation of the present invention will be further described below in conjunction with the drawings and embodiments.

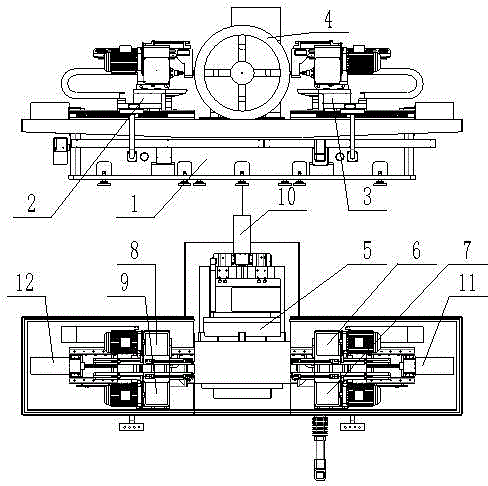

[0015] like figure 1 As shown, it shows a schematic diagram of the overall structure of a CNC four-axis ring die deep hole drilling machine. The machine tool is composed of the following components: bed 1, left slide 2, right slide 3, ring mold 4, CNC rotary Table 5, first right spindle 6, second right spindle 7, first left spindle 8, second left spindle 9, X-axis servo system 10, Z-axis right servo system 11, Z-axis left servo system 12.

[0016] figure 1 The components of the CNC four-axis ring die deep hole drilling machine tool are assembled according to the following method. figure 1 CNC rotary table 5, left slide table 2, right slide table 3, and middle slide table are respectively installed on the bed 1 in the middle, so that the front and rear motion tracks of the guide rails of the CNC rotary table are perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com