Conical spring washer for mounting a stator in the housing of an electrical machine

A tensioning wheel and housing technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as the cost of vibration reduction solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

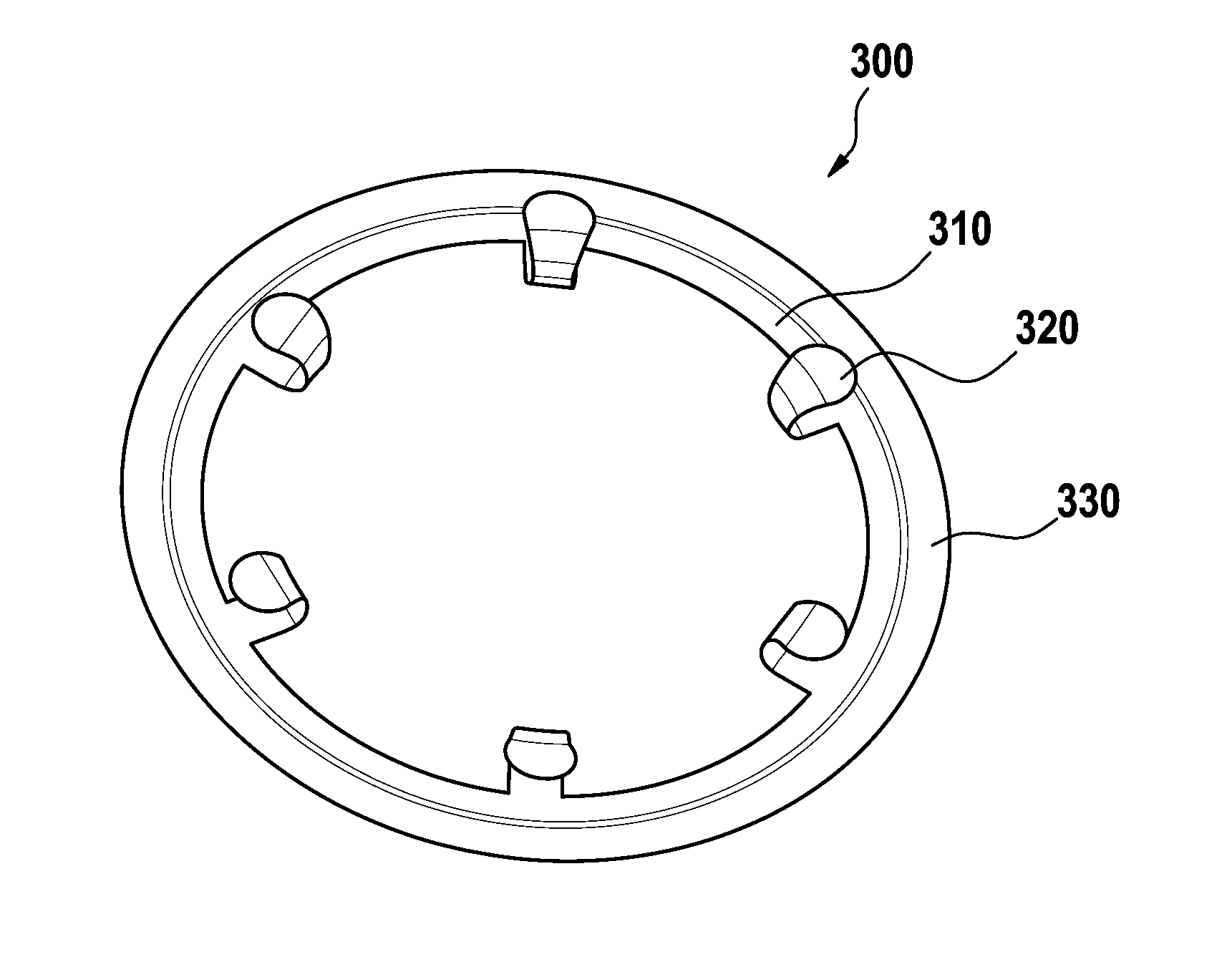

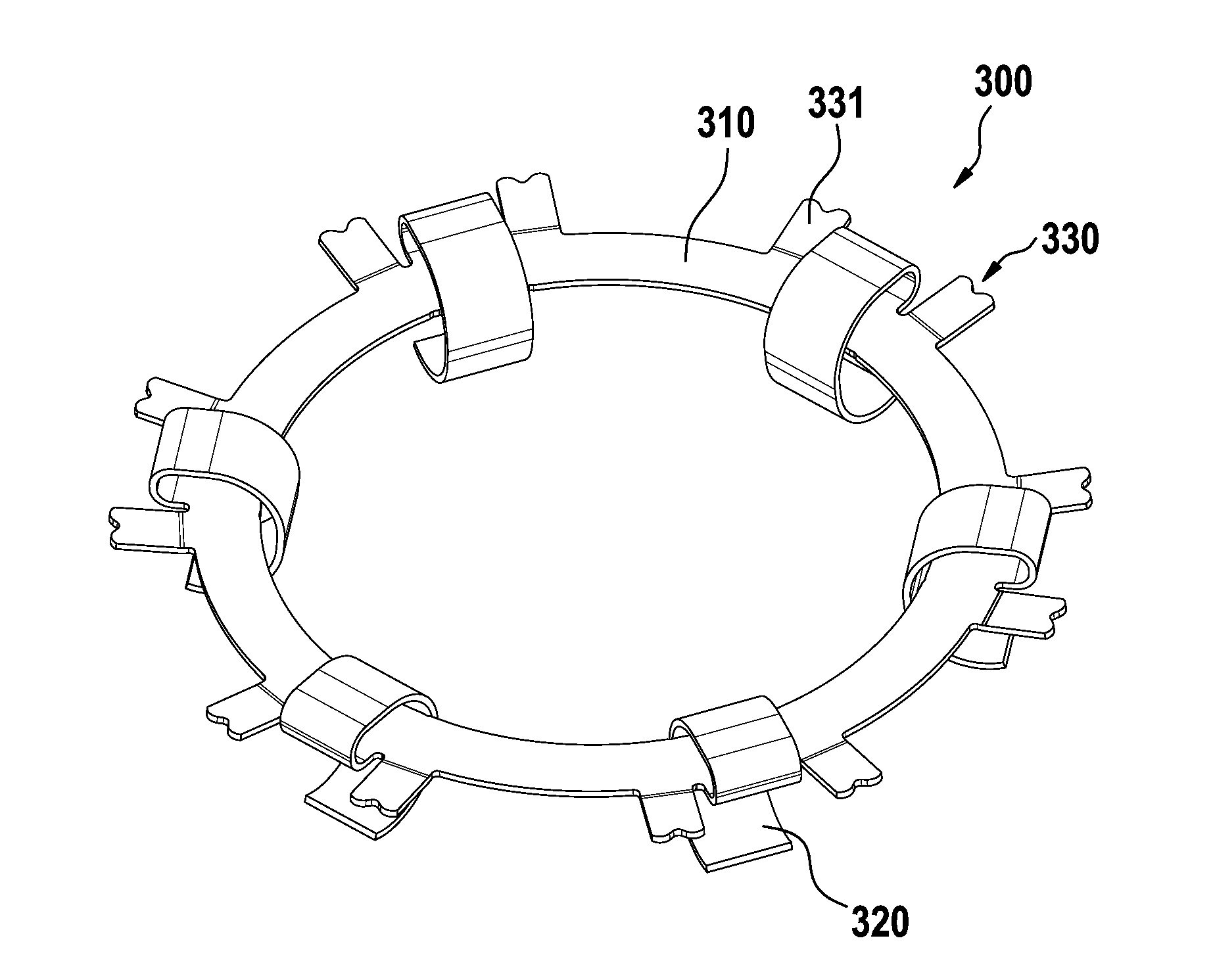

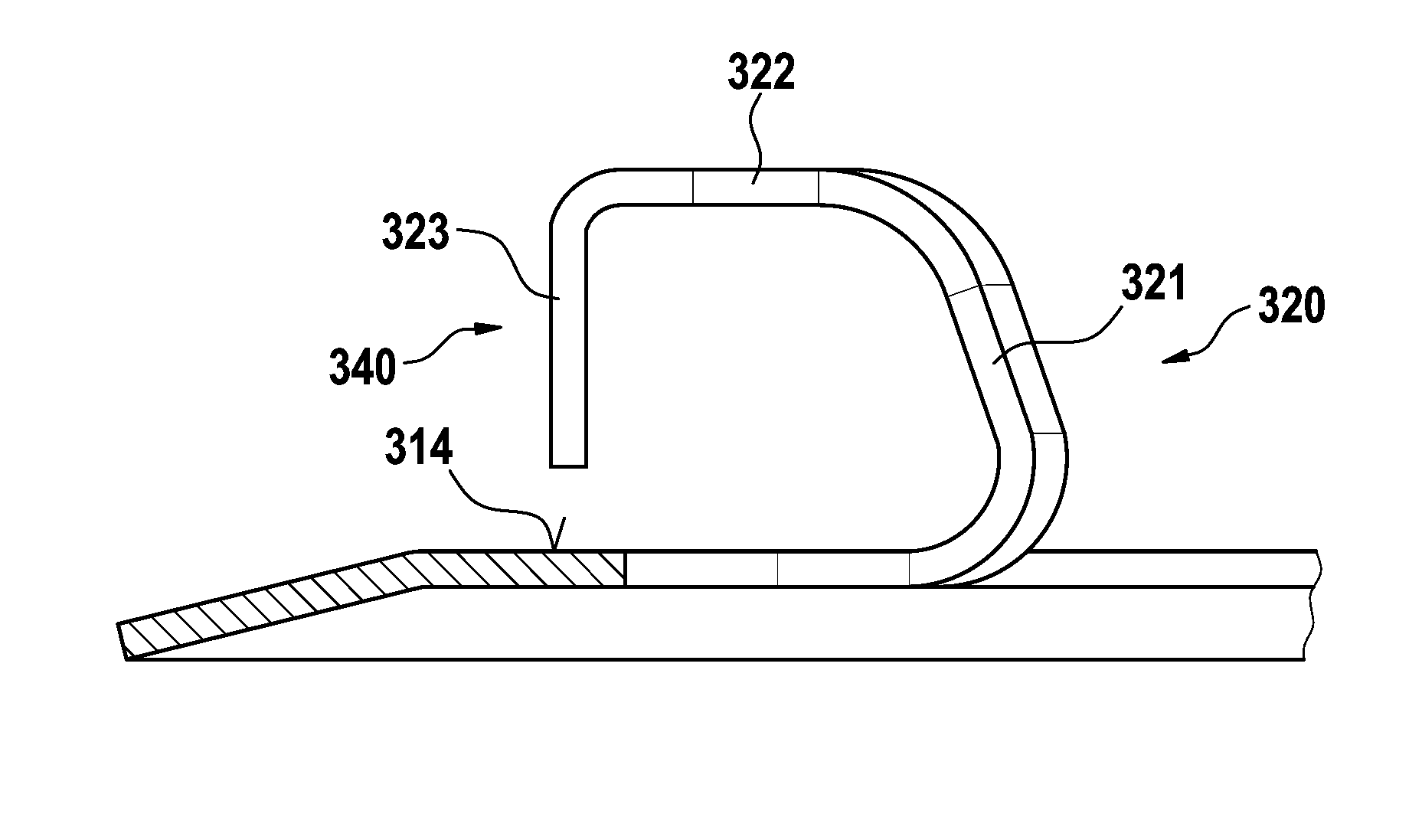

[0035] FIG. 1 is a perspective view of an electric machine 100 according to the invention. In the present example, the drive components, which are designed as hydraulic pumps, in particular the electric motors, which are designed as cooling circuit pumps, are shown here in a partially cutaway state. The motor 100 comprises a housing 110 made of a suitable material, such as plastic or metal, with an inner cavity 113 having a substantially circular cross-section, and an annular stator 200 disposed in the housing cavity and snapped into the annular The rotor 400 in the stator 200. In the hydraulic pump shown here, the rotor is arranged in an intermediate housing which separates the rotor chamber, which is flushed by the fluid from all sides, from the stator chamber. The intermediate housing is here formed by a cover element which closes the housing chamber on one side. According to the invention, stator 200 is fixed in its assembly position by means of tensioning pulley 300 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com