Non-contact angle sensor

An angle sensor, non-contact technology, applied in the direction of conversion of sensor output, instruments, and the use of electromagnetic/magnetic devices to transmit sensing components, etc., can solve problems such as the larger angle swing of the rotating shaft 10 and the poor durability of the angle sensor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

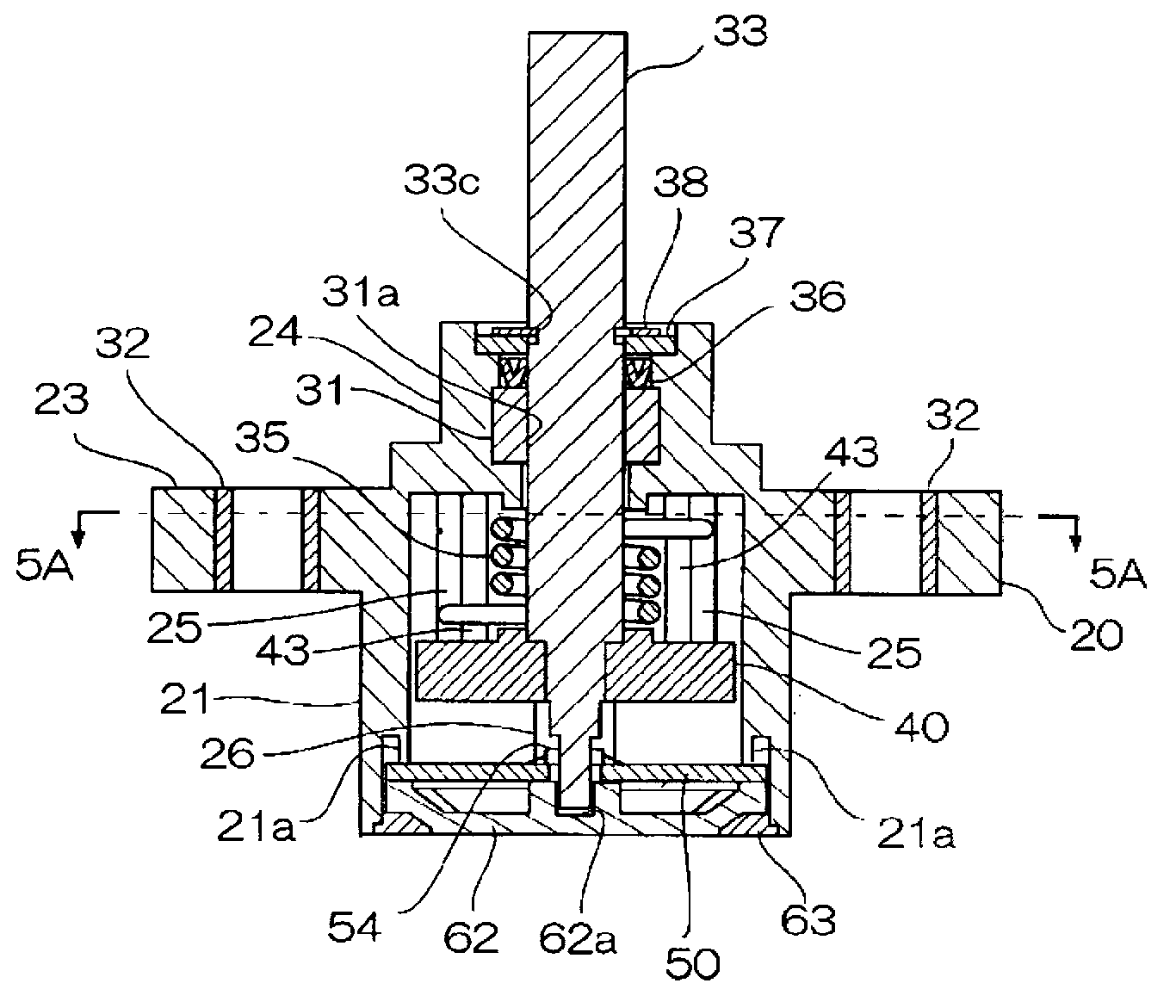

[0029] Embodiments of this invention are described by way of examples with reference to the drawings.

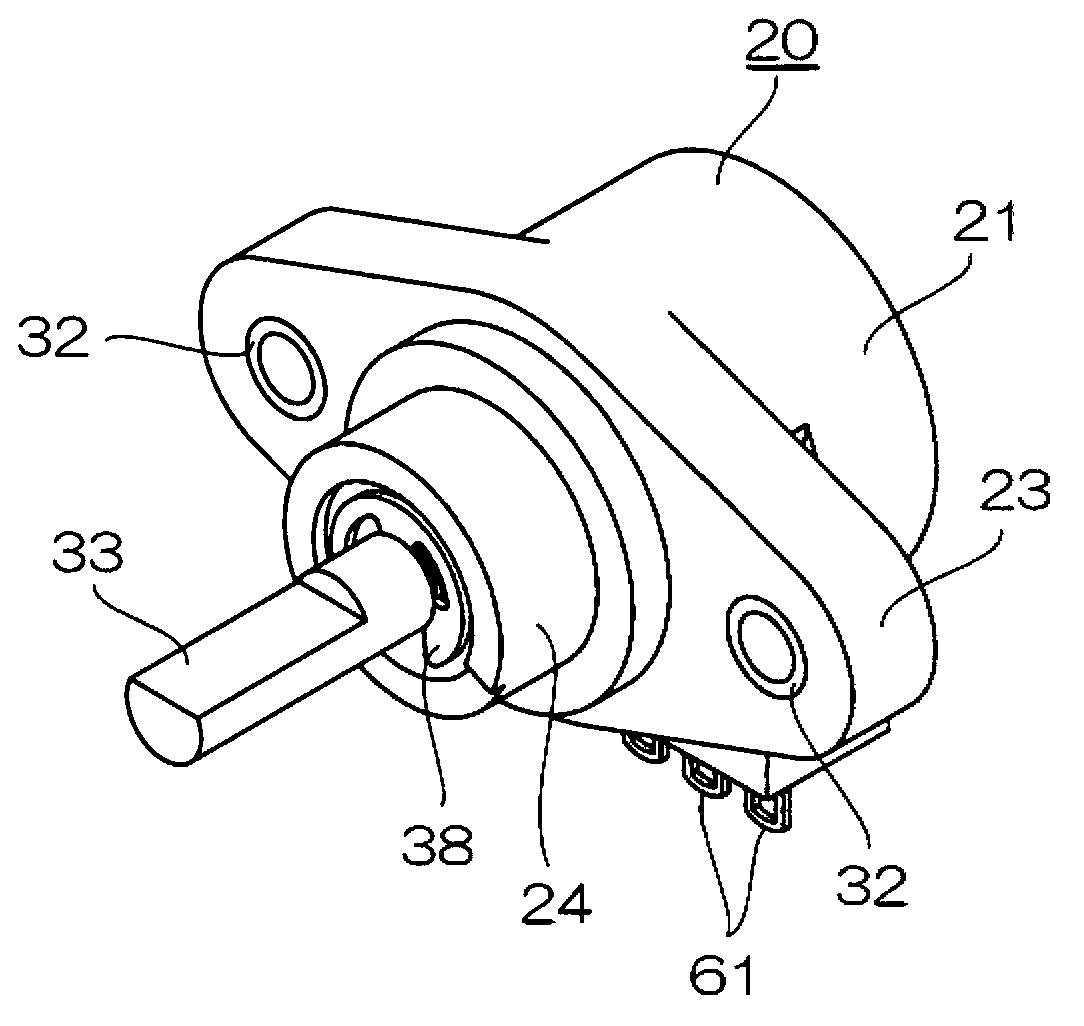

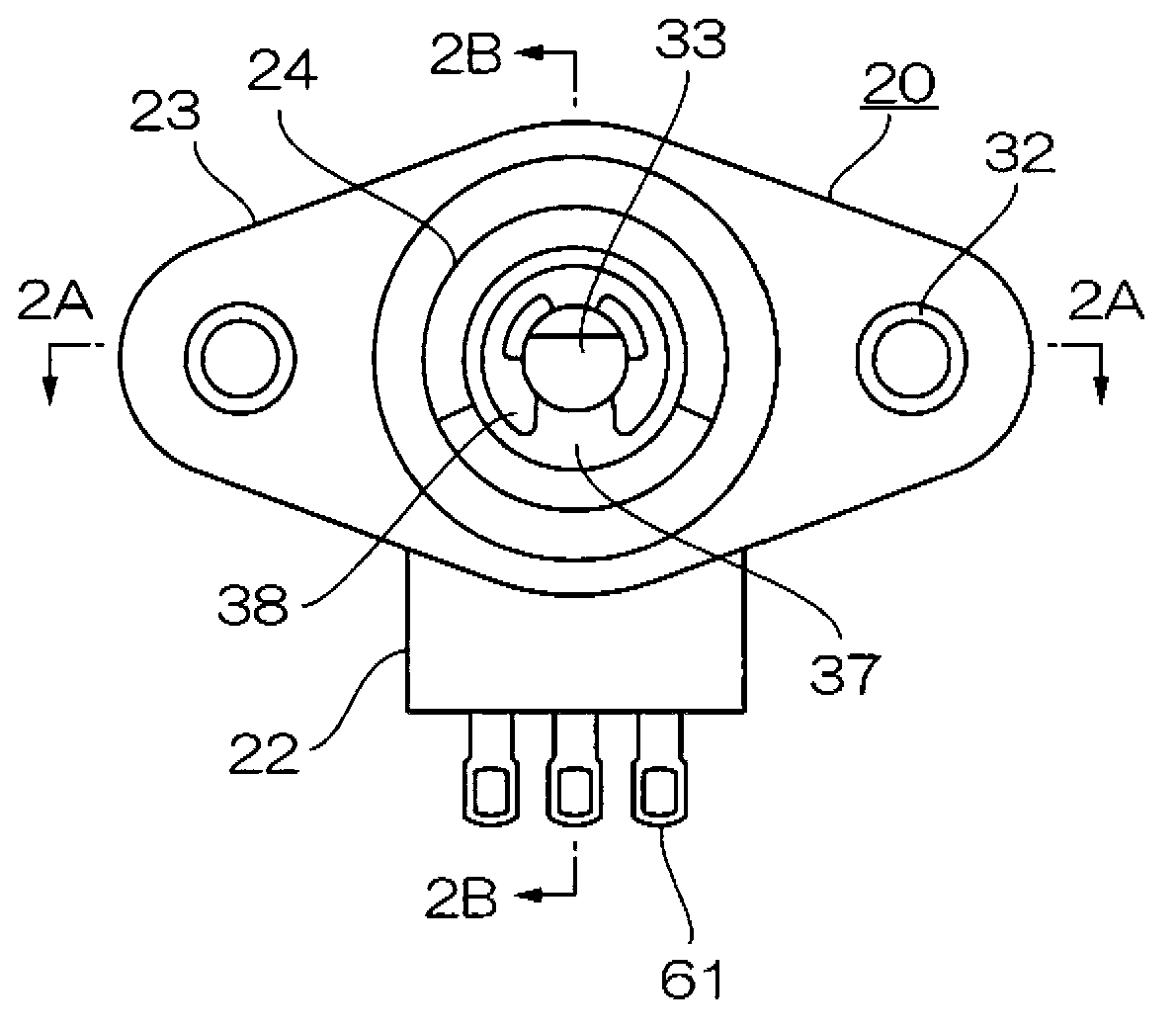

[0030] The non-contact angle sensor of this invention is a sensor that rotates a rotating shaft to output an electrical signal corresponding to a rotation angle from a neutral angle position. Figure 1A , 1B Showing the appearance of an embodiment of the non-contact angle sensor of this invention, Figure 2A express Figure 1B 2A-2A sectional view, Figure 2B express Figure 1B The structure of the 2B-2B section. in addition, image 3 It is a diagram decomposed and shown in each part.

[0031] The housing 20 has a cylindrical receiving portion 21. On the back side of the receiving portion 21, a square plate-shaped terminal lead-out portion 22 protrudes from its outer peripheral surface in a radial direction. On the front side of the receiving portion 21, a pair of mounting portions 23 protrudes greatly from the outer peripheral surface in the radial direction opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com