Impeller of washing machine and washing machine with the impeller

A washing machine and pulsator technology, applied in the field of washing machines, can solve the problems of large swing angle, severe vibration, and increase the size of the outer cylinder, and achieve the effects of stable rotation, good deviation correction effect and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

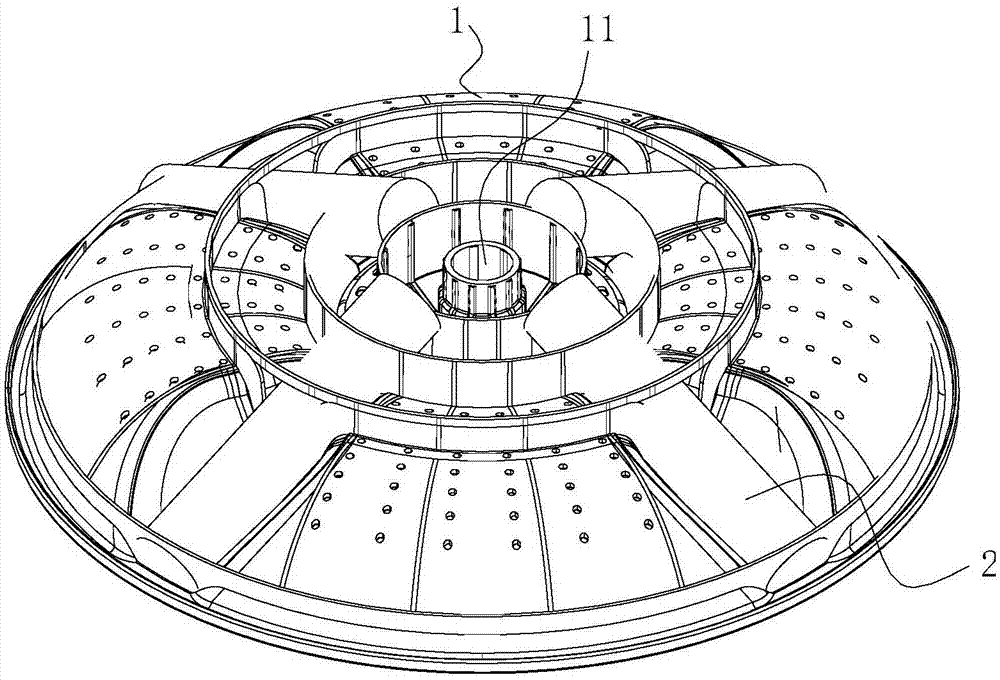

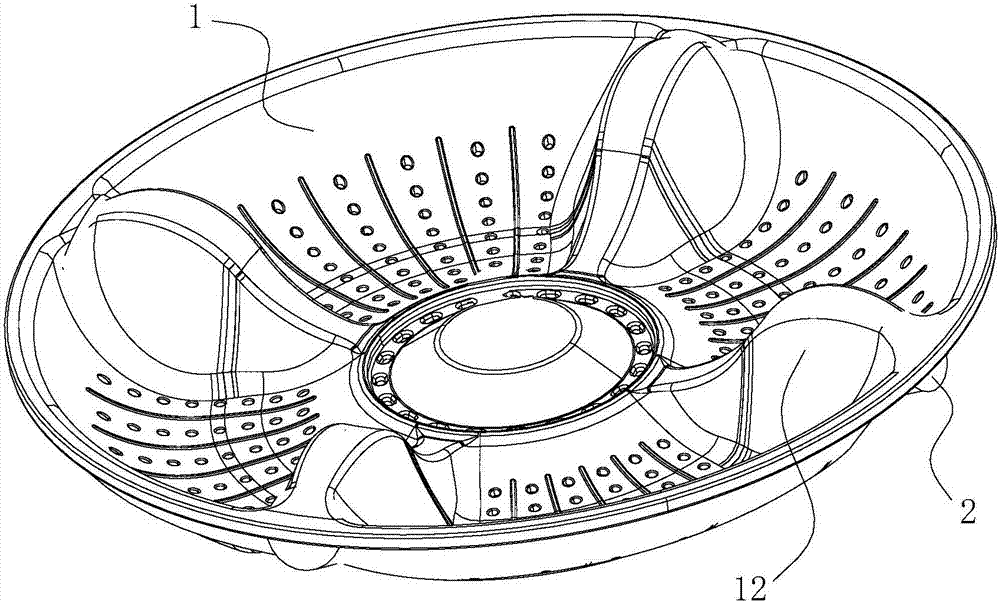

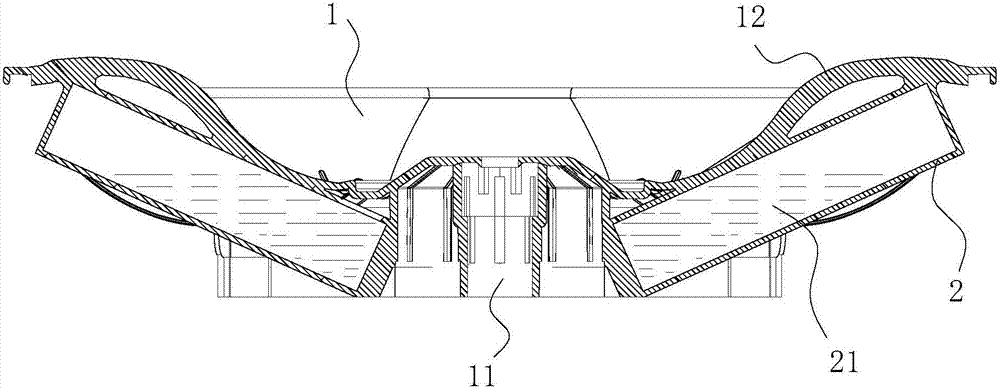

[0032] This preferred embodiment discloses a washing machine pulsator. Such as figure 1 with figure 2 As shown, the pulsator includes a pulsator body 1 capable of rotating around the connecting shaft hole 11 , four balance cylinders 2 are uniformly arranged on the pulsator body 1 , and each balance cylinder 2 is arranged along the radial direction of the pulsator body 1 . The number of balance cylinders 2 is not limited to four, but can also be two, three, five or other numbers.

[0033] A balance cylinder 2 extending radially along the pulsator body 1 is arranged on the pulsator body 1, so that the center of mass of the washing machine can move to the side of the drive motor, reduce the swing angle of the inner cylinder during rotation, and reduce the amplitude of the inner cylinder, thereby effectively Reduce the overall vibration of the washing machine to ensure that the entire washing machine has better balance and low noise when the inner drum rotates.

[0034] In ord...

Embodiment 2

[0042] This preferred embodiment discloses a washing machine pulsator, the structure of which is basically the same as that of the preferred embodiment 1, except that a balance ring is provided on the outer periphery of the pulsator body instead of a balance cylinder. The pulsator body is closer to the drive motor than the inner cylinder. A balance ring on the pulsator body can make the center of mass of the washing machine move to the side of the drive motor, reduce the swing angle of the inner cylinder during rotation, and reduce the vibration of the inner cylinder, thereby effectively Reduce the overall vibration of the washing machine, and the noise is low.

Embodiment 3

[0044] This preferred embodiment discloses a pulsator for a washing machine, the structure of which is basically the same as that of the preferred embodiment 1, the difference is that, as Image 6 with Figure 7 As shown, in addition to the four balance cylinders 2 provided on the pulsator body 1, a balance ring 3 is also provided on the outer periphery of the pulsator body 1; the structure of the balance ring 3 can be the same as that of the existing balance ring. The simultaneous use of the balance cylinder 2 and the balance ring 3 ensures better balance performance and smaller vibration amplitude of the whole machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com