Dispensing liquids from a container coupled to an integrated pump cap

A liquid container and liquid technology, applied in the direction of liquid distribution, transportation or transfer devices, distribution devices, special distribution devices, etc., can solve the problems of precision and overflow, and achieve the effect of easy pollution, easy handling, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

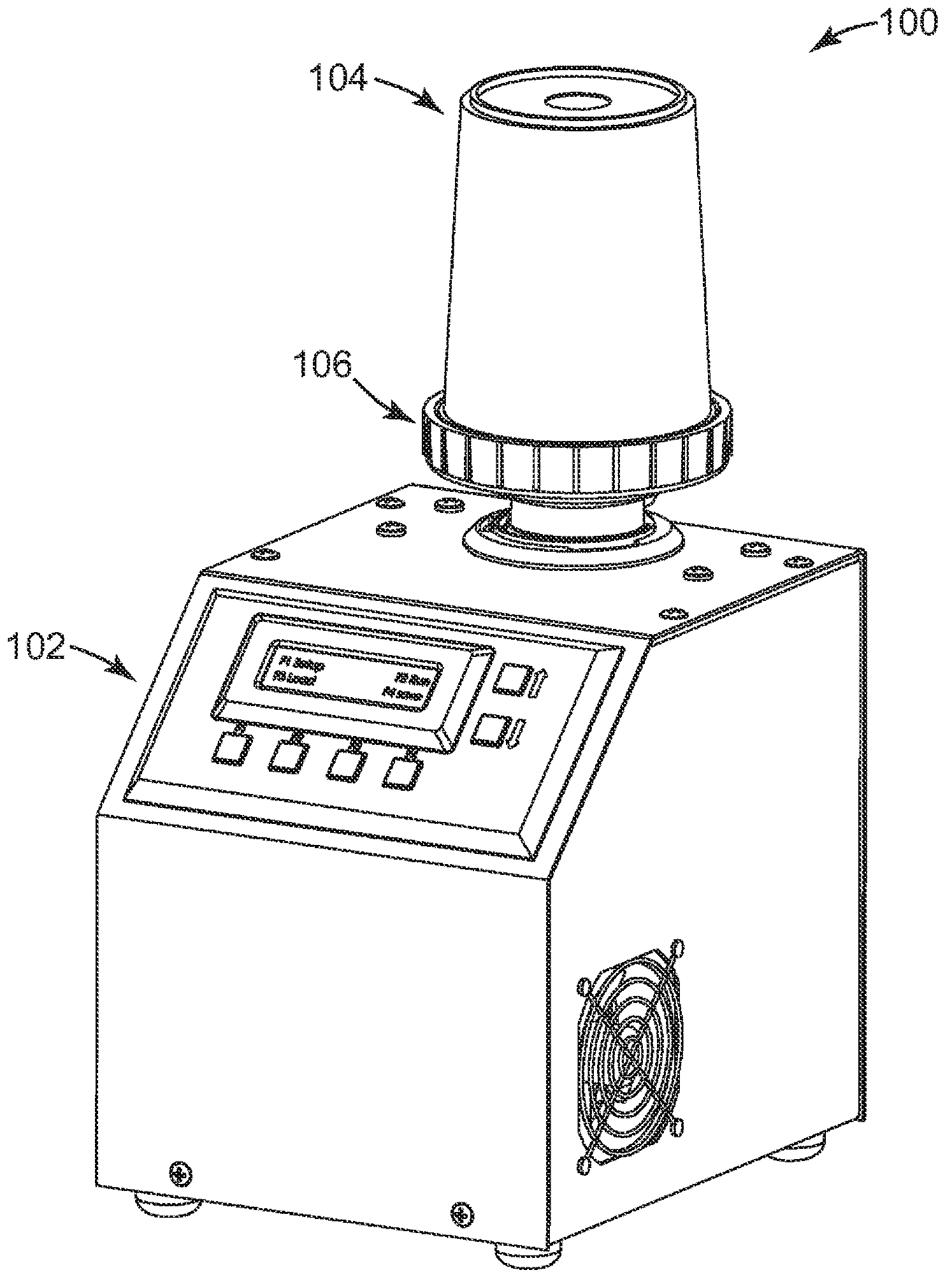

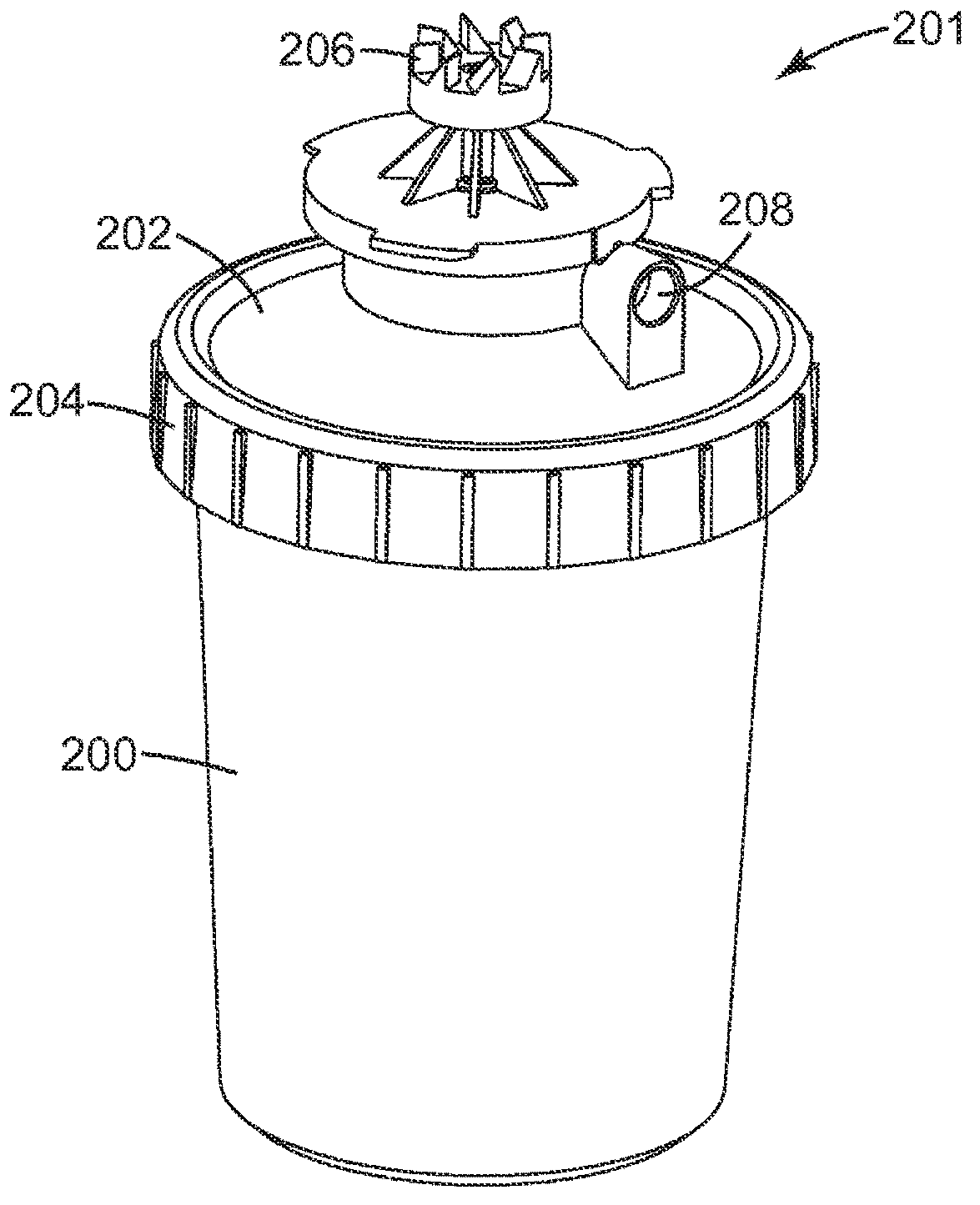

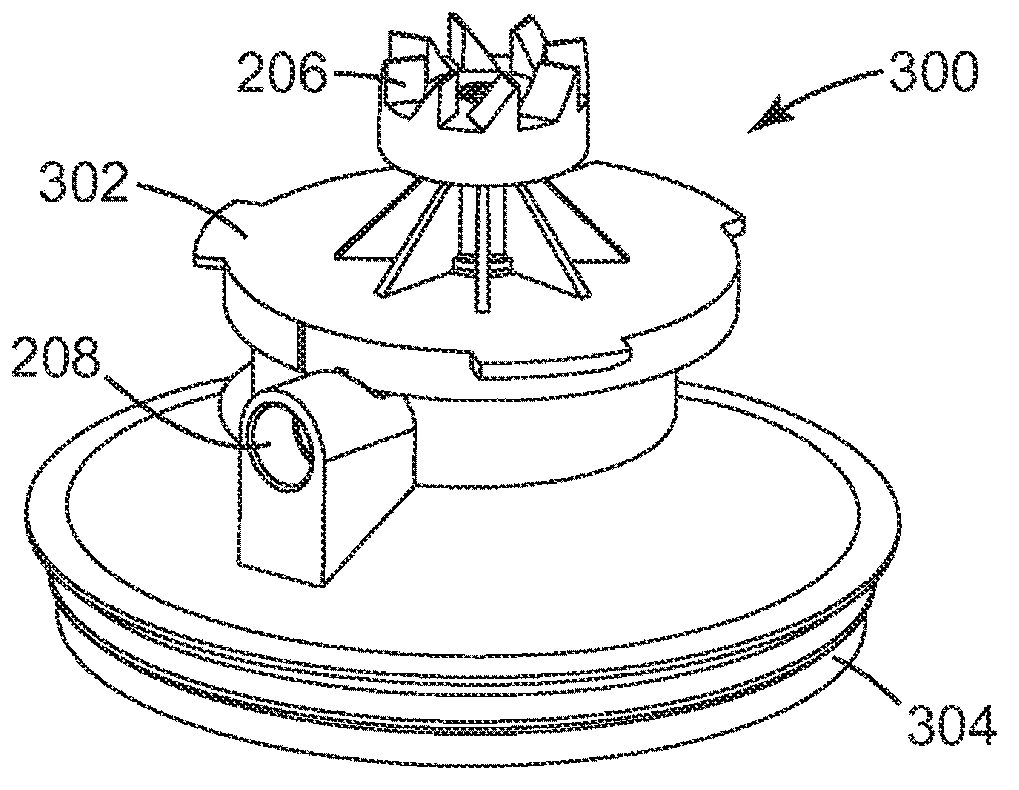

[0069] Embodiment 1. A device comprising a liquid container coupled to an integral pump housing including a pump coupled to an inlet port of the container and to an output port that is Configured to dispense liquid from the liquid container when the pump is activated.

Embodiment 2

[0070] Embodiment 2. A system comprising:

[0071] a liquid container comprising an integral pump housing;

[0072] a motor coupled to the liquid container configured to drive a pump in the integral pump housing to dispense a specified amount of liquid; and

[0073] A device coupled to a liquid container such that liquid dispensed from the liquid container is received by the device.

Embodiment 3

[0074] Embodiment 3. A method for dispensing a specified amount of liquid comprising:

[0075] receiving instructions for dispensing a specific amount of liquid;

[0076] activating a motor coupled to a liquid container including a pump in an integral pump housing; and

[0077] The motor is stopped when a certain amount of liquid has been dispensed from the liquid container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com