Fiber grating vertical strain sensor

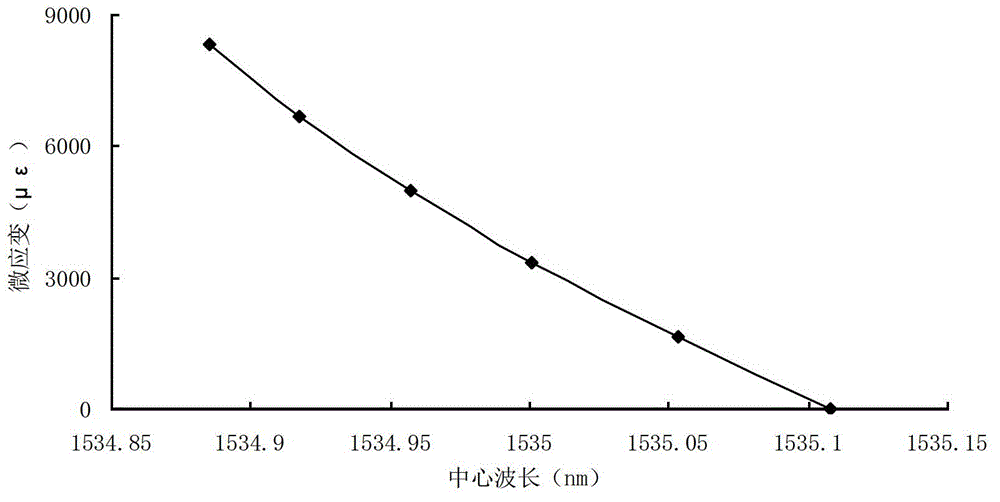

A technology of strain sensor and optical fiber grating, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of test data deviation, large size, difficult combination of test piece block and structural layer, etc., to achieve measurement and avoid strain distribution the effect of the change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Attached below figure 1 And attached figure 2 The present invention is described in detail:

[0028] The fiber grating vertical strain sensor of the present invention mainly consists of a sensitive grating 4, a temperature compensation grating 11, a fixed base 1, a protective shell 2, an inner hollow pillar 3, a fixed screw 5, an orientation screw 6, an optical fiber steering hole 10, and an optical fiber lead-out protection Component 7, armored optical cable 8 and pigtail 9 etc. composition.

[0029] Fixed base 1 comprises upper base 12 and lower base 13; Pasted on the inner wall of the hollow pillar 3, the optical fiber 14 penetrates from the side of the upper base 12, passes through the inner hollow pillar 3, and passes out from the side of the lower base 13. The side of the upper base 12 and the side of the lower base 13 are on the same side of the hollow pillar 3 . A protective casing 2 is provided on the outside of the hollow pillar 3 . The upper base 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com