An Integrated Modular Leg System for Hexapod Robots

A hexapod robot and integrated module technology, applied in the field of integrated modular leg system, can solve the problems of lack of omni-directional force perception function, lack of integration of legs, low flexibility, etc., and achieve light weight and compact structure , The effect of simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

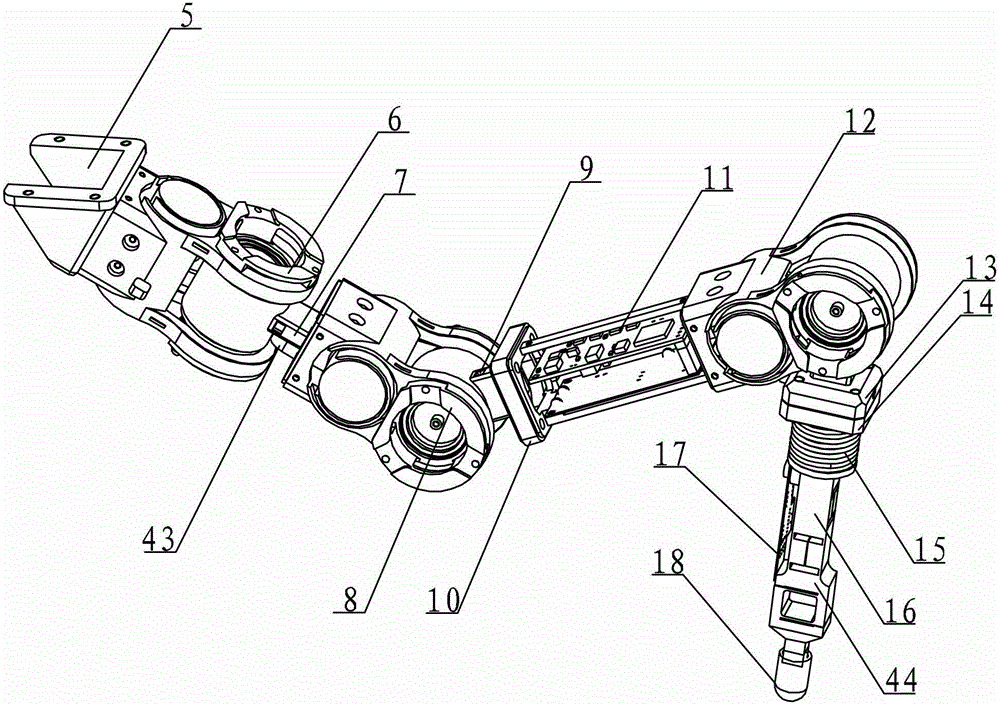

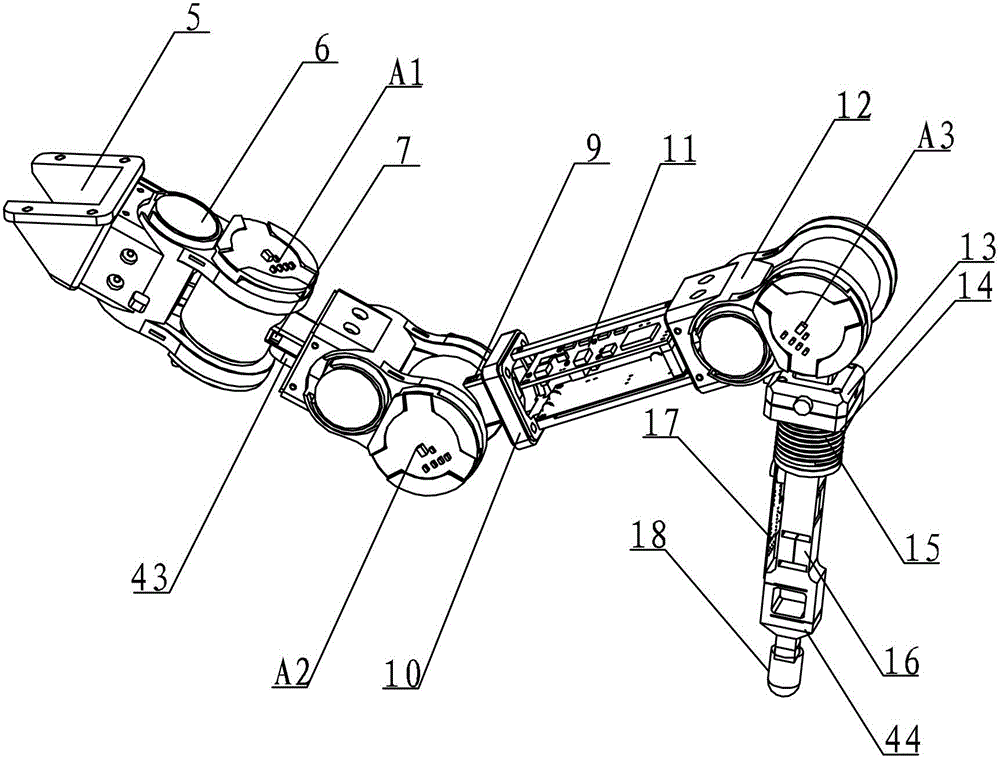

[0014] Specific implementation mode one: combine Figure 1 to Figure 3 with Figure 8 Describe this embodiment, an integrated modular leg system for a hexapod robot in this embodiment The integrated modular leg system includes a mechanical mechanism and a control part, the control part is installed on the mechanical mechanism,

[0015] The mechanical mechanism includes a triangular connector 5, a trunk-base joint 6, a base beam 43, a base-femur joint 8, a femoral beam 10, a femur-tibial joint 12, a connector 13, and a flange 14 , spring 15, foot-end frame 44 and foot-end rubber cover 18, triangle connector 5, trunk-base joint 6, base beam 43, base-femur joint 8, femur beam 10 and femur-shin The joints 12 are connected sequentially from left to right, the flange 14 is connected with the femur-tibia joint 12 through the connector 13, the upper end of the foot end frame 44 is set in the flange hole of the flange 14, and the spring 15 is set on the foot end The top of frame 44, ...

specific Embodiment approach 2

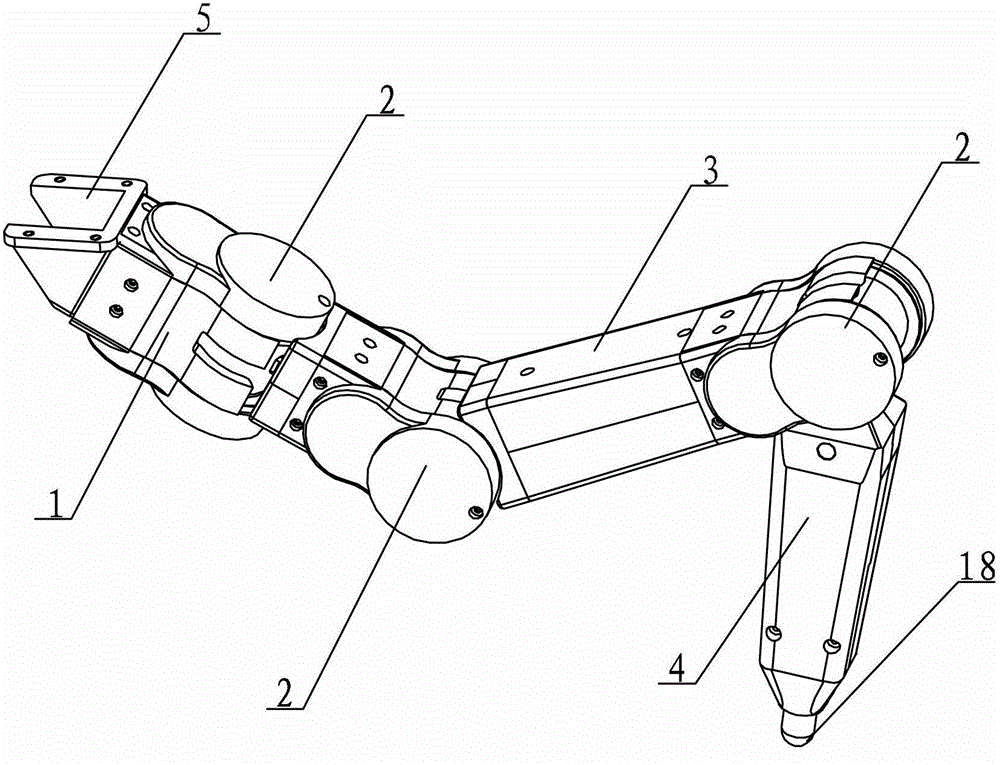

[0020] Specific implementation mode two: combination figure 1 Describe this embodiment, the integrated modular leg system of this embodiment also includes a base joint packaging shell 1, a plurality of wire retaining plates 2, a thigh joint packing shell 3 and a tibial joint packing shell 4, the base joint packing shell 1 is arranged on the trunk-base joint 6, the femur packing shell 3 is set on the base-femur joint 8, the tibial packing shell 4 is set on the femur-tibia joint 12, the trunk-base joint 6. The two ends of the base joint-femoral joint 8 and the femoral joint 12 are respectively provided with a line guard 2 . Such setting not only effectively protects various components of the leg system, but also makes the leg system more beautiful and compact. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination Figure 4 with Image 6 To illustrate this embodiment, the trunk-base joint 6, base-femur joint 8 and femur-tibia joint 12 of this embodiment all include a joint housing 26, a first bearing seat 23, a second bearing seat 24 and The internal transmission system 25 is arranged in the joint casing 26, and the two ends of the joint casing 26 are respectively provided with a first bearing seat 23 and a second bearing seat 24. Such setting makes it more convenient to maintain and replace when a situation occurs, and it is more convenient to use. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com