Electric commercial vehicle battery box single-trip replacement robot

A technology for battery boxes and commercial vehicles, which is applied to electric power units, power units, vehicle components, etc., can solve the problems of unreasonable limit mode, large working stroke and high complexity, so as to shorten the time of battery replacement and reduce the working stroke. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

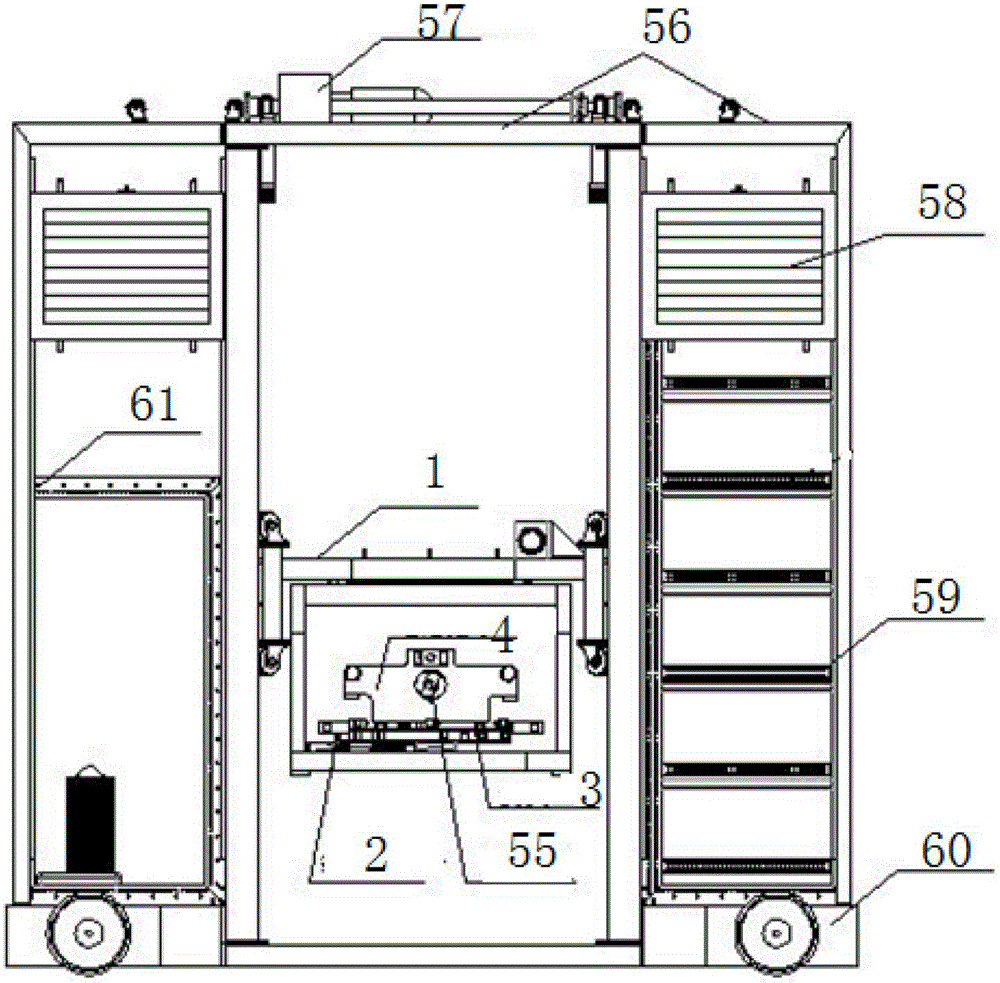

[0099] figure 1 , figure 2 Among them, the one-way replacement robot for the electric commercial vehicle battery box of the present invention includes a frame assembly 56, and a sheet metal skin is arranged outside the frame assembly 56 to wrap it up as an external decorative skin, and the decorative skin is divided into several parts. The components are connected and assembled by bolts, which is not only beautiful, but also can effectively prevent foreign matter from entering the battery swap robot, causing damage to the equipment and affecting normal work.

[0100] On both sides of the frame assembly 56, there are respectively a control cabinet 61 and temporary storage racks 59 for the battery box;

[0101] The top of the frame assembly 56 is provided with a lifting transmission assembly 57 for the lifting of the lifting assembly 1, while counterwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com