Nut box

A nut and vertical plate technology, used in screwdrivers, wrenches, manufacturing tools, etc., can solve the problems of high labor intensity, low assembly efficiency, and difficult assembly of workers, and achieve the goal of reducing labor intensity, improving efficiency, and improving assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

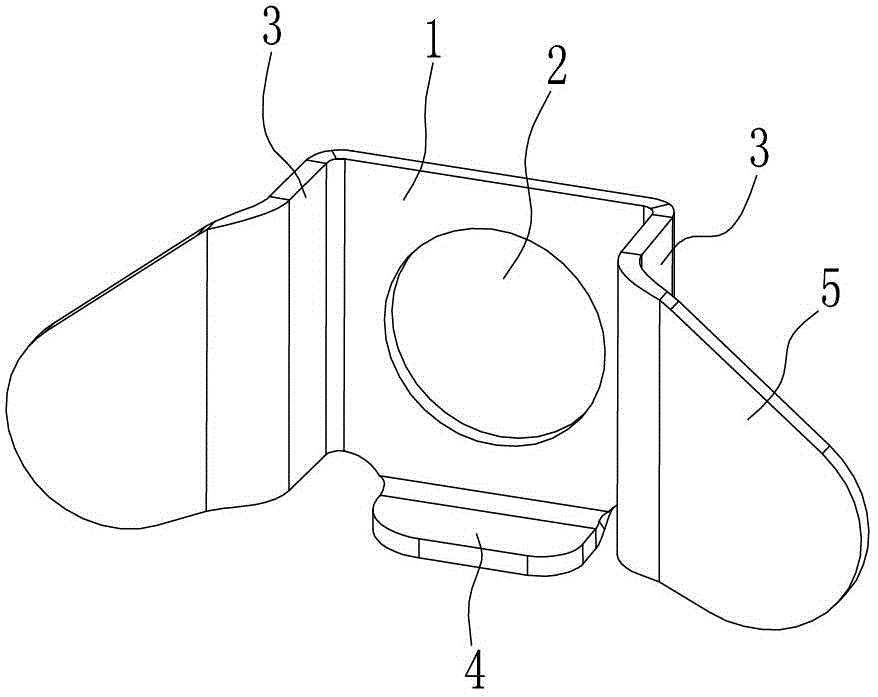

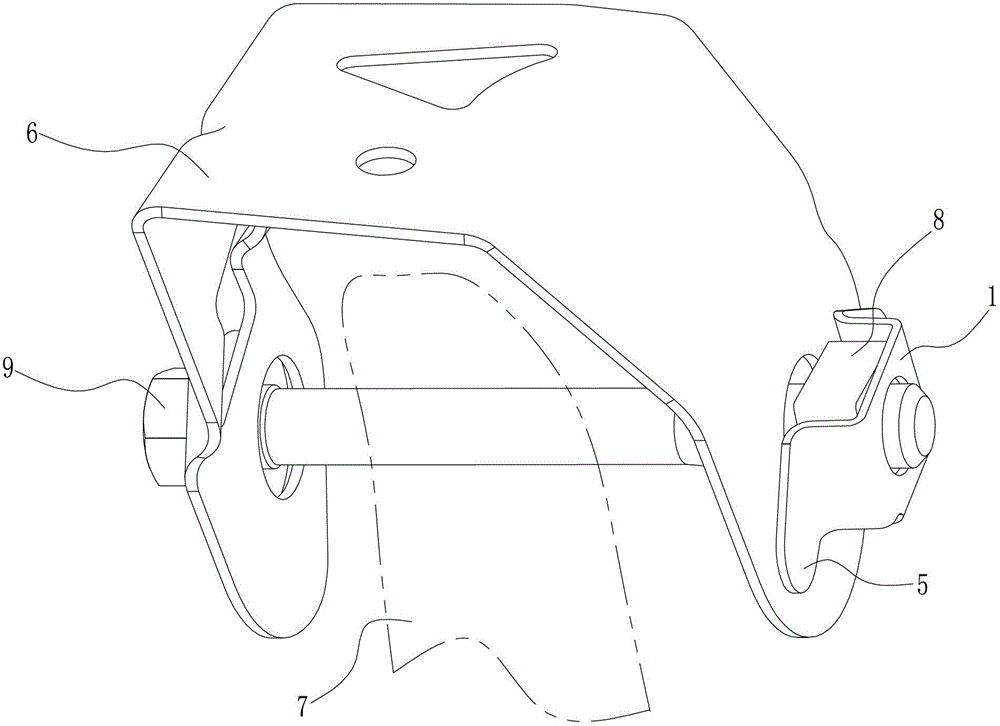

[0013] like figure 1 As shown, the present invention is formed by stamping a steel plate, and is composed of a vertical plate 1, an end plate 3, a supporting plate 4 and a wing plate 5, and the specific material and thickness can be determined according to actual needs. The vertical plate 1 is a rectangular vertical plate structure, and a circular via hole 2 is opened in the middle of the vertical plate 1 . Both ends of the vertical plate 1 are symmetrically provided with end plates 3, the end plates 3 are perpendicular to the vertical plate 1, and the end plates 3 and the vertical plate 1 are connected as a whole. The upper end of the end plate 3 is flush with the upper end of the vertical plate 1 , and the lower end of the end plate 3 is flush with the lower end of the vertical plate 1 .

[0014] like figure 1 As shown, a wing plate 5 is vertically conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com