Edge precision control method of large aperture optical element being processed through air bag polishing

A technology of airbag polishing and optical components, which is applied in metal processing equipment, optical surface grinders, grinding/polishing equipment, etc., can solve the problems of destroying the accuracy of the main surface, high risk, and high cost, so as to improve processing efficiency, simple operation, Effect of Accuracy Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

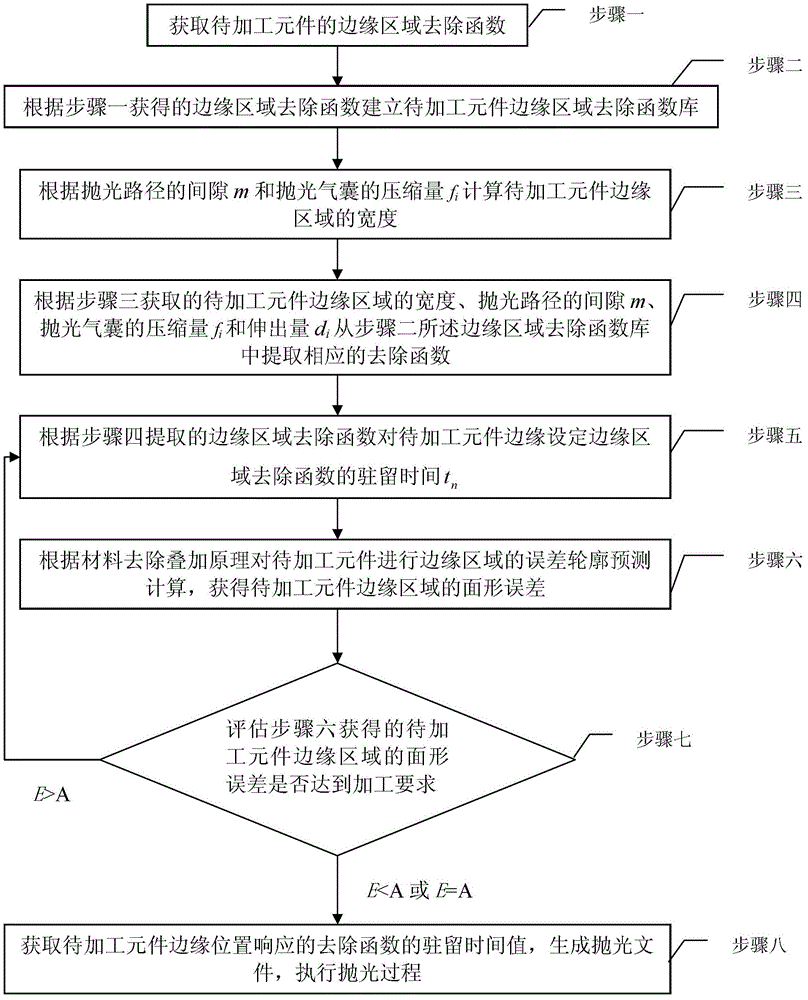

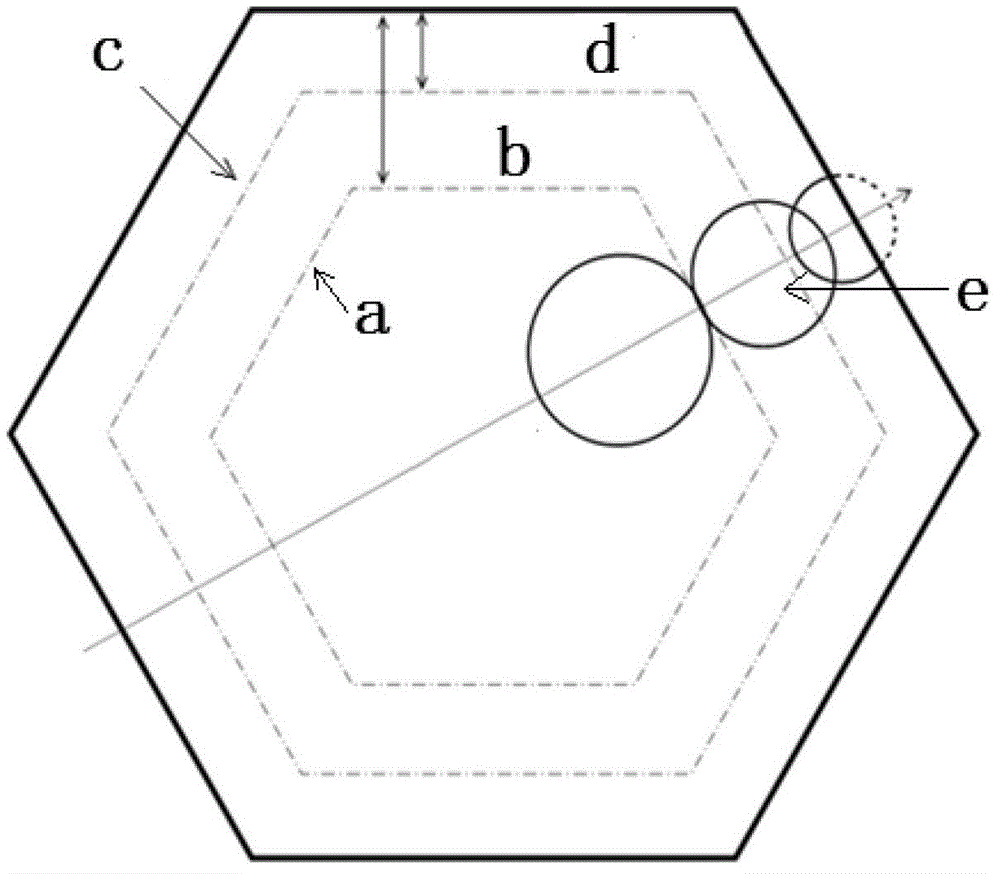

[0035] Specific implementation mode 1. Combination Figure 1-3 This specific embodiment will be described. The method for controlling the edge accuracy of large-diameter optical elements in airbag polishing process comprises the following steps:

[0036] Step 1: Obtain the edge area removal function of the material corresponding to the component to be processed;

[0037] Step 2: Establish the edge area removal function library of the component to be processed according to the edge area removal function obtained in step 1. The edge area removal function library is based on the compression amount f of the polishing airbag i and overhang d i One-to-one corresponding edge area removal function;

[0038] Step 3: According to the gap m of the polishing path and the compression amount f of the polishing air bag i Calculate the width of the edge area of the component to be processed;

[0039] Step 4: According to the width of the edge area of the component to be processed obt...

specific Embodiment approach 2

[0052] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the process of setting the dwell time of the edge region removal function for the edge of the component to be processed according to the corresponding edge region removal function extracted in step 4 in step 5 is as follows , where the error distribution in the marginal region during this process is e 0 (x,y) edge , the root mean square value of the error distribution in the marginal area is E 0 :

[0053] Step 5A: Set the residence time t for n edge area removal functions on the edge area of the component to be processed n , i=1, 2...n;

[0054] Step 5B: Calculate the error distribution e of the edge region at the dwell time in Step 5A 0 (x,y) edge ;

[0055] e 0 ( x , y ) edge = Σ i ...

specific Embodiment approach 3

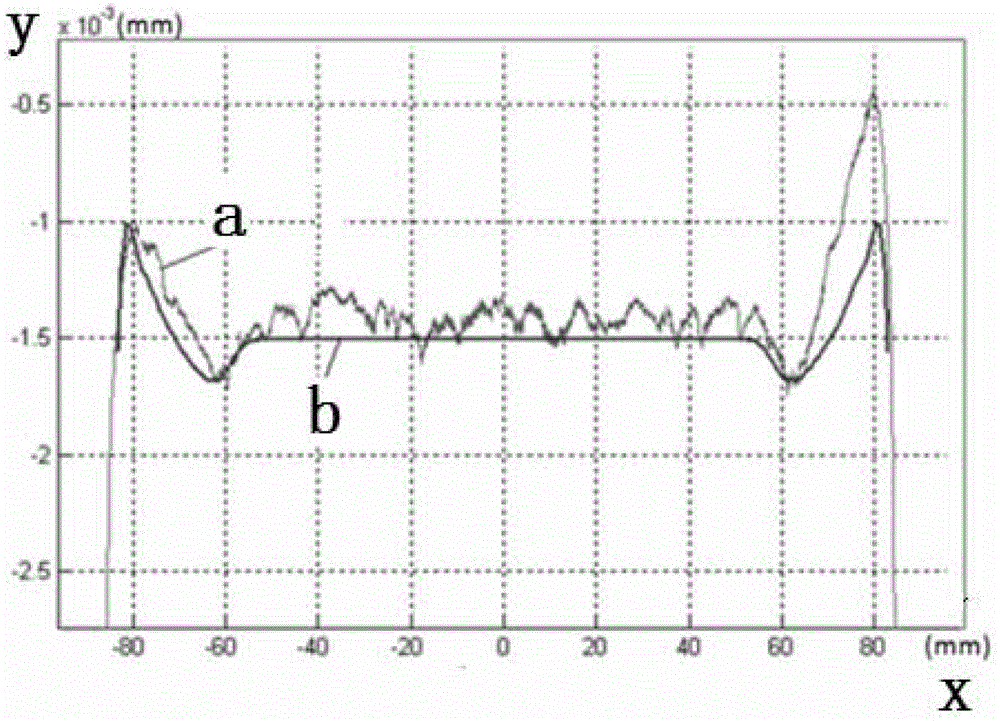

[0061] Specific Embodiment 3. The difference between this specific embodiment and specific embodiment 1 is that in the step 6, the error contour prediction calculation of the edge area of the element to be processed is performed according to the principle of material removal and superposition, and the surface shape error of the edge area of the element to be processed is obtained. Root mean square value E, its process is:

[0062] Step 6A: The gap m of the polishing path, the edge area of the component to be processed has n edge area removal functions where i=1, 2...n; f i Compression of polished airbag, d i is the amount of protrusion; then the error distribution e(x, y) of the edge area of the component to be processed edge Calculated by the following formula:

[0063] e ( x , y ) edge = Σ i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com