Laser tracker-based machine tool error dynamic compensation method

A technology of laser tracker and error dynamics, which is applied in the direction of automatic control devices, metal processing machinery parts, manufacturing tools, etc., can solve the problem of detection efficiency, detection accuracy and lack of versatility, and cannot meet the requirements of high-precision and fast detection. Interferometry has a long detection period and other problems, and achieves the effects of real-time tracking measurement, fast installation and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

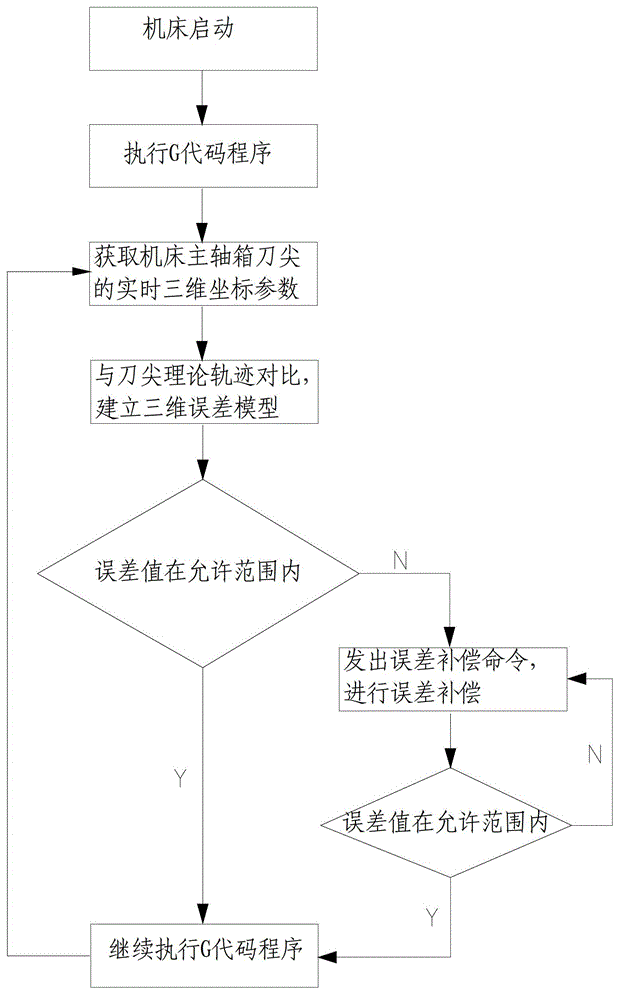

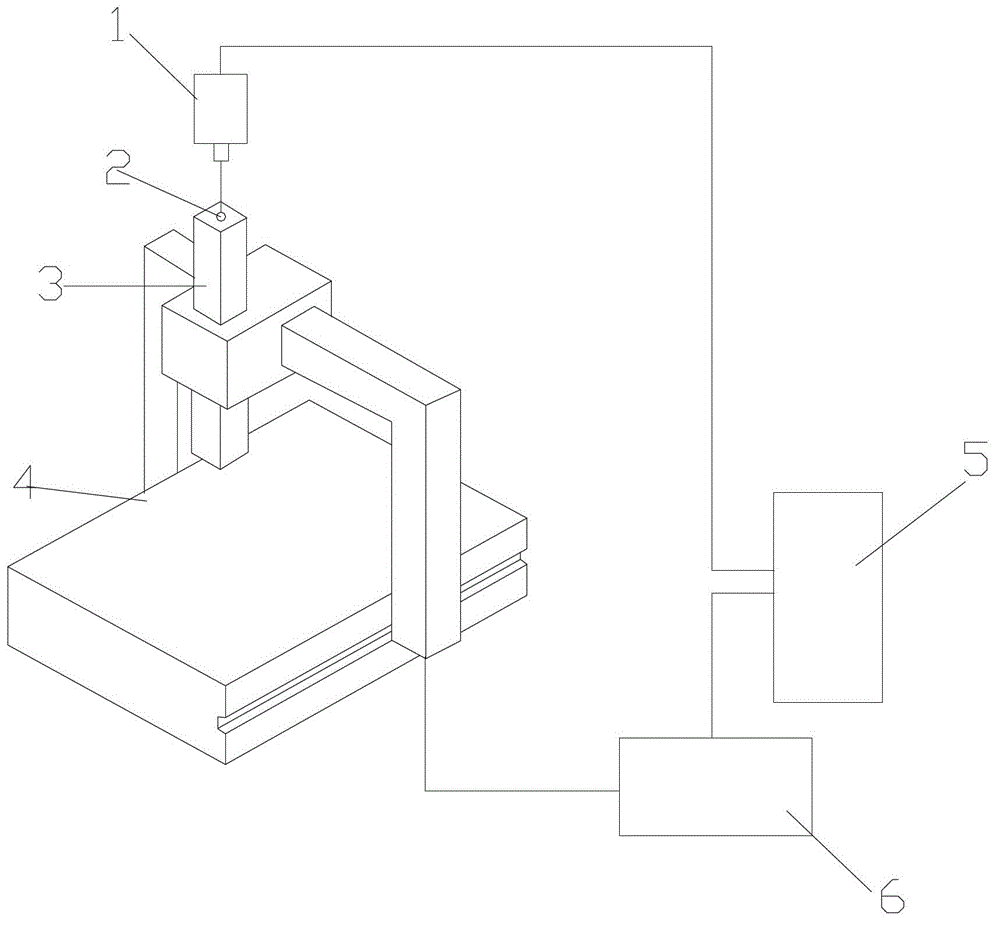

[0017] figure 1 It is a structural schematic diagram of the compensation system of the present invention, figure 2 It is a block diagram of the principle of the present invention, as shown in the figure: the method for dynamic compensation of machine tool errors based on laser trackers in this embodiment includes the following steps;

[0018] a. The machine tool 4 starts and executes the numerical control program (G code program), obtains the real-time three-dimensional coordinate parameters of the tool tip on the machine tool spindle box 3 through the laser tracker 1, and sends it to the computer 5;

[0019] b. Comparing the real-time three-dimensional coordinate parameters obtained in step a with the theoretical running trajectory of the tool tip on the machine tool spindle box 3 stored in the computer 5, establishing a three-dimensional space error model, and decomposing the tool tip on the machine tool spindle box 3 from the three-dimensional space error model The error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com