Ultra-precision processing clamp with universal regulation and self locking functions

A technology of ultra-precision machining and universal adjustment, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of not having both universal adjustment function and self-locking function, and achieve large locking force, The effect of high adjustment accuracy and convenient universal adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

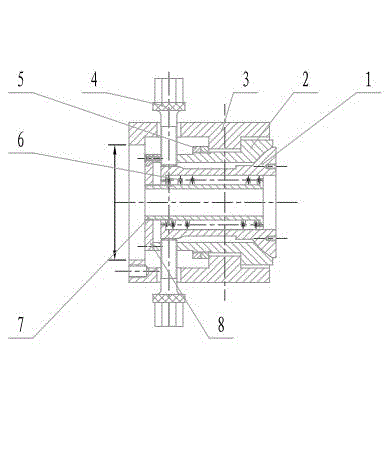

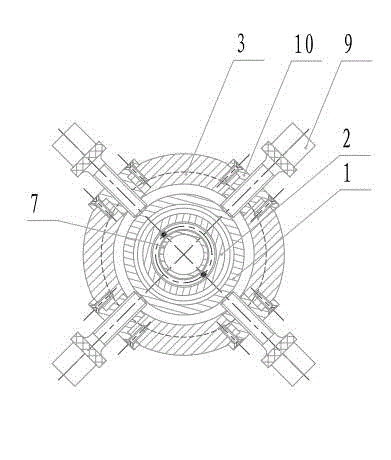

[0018] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

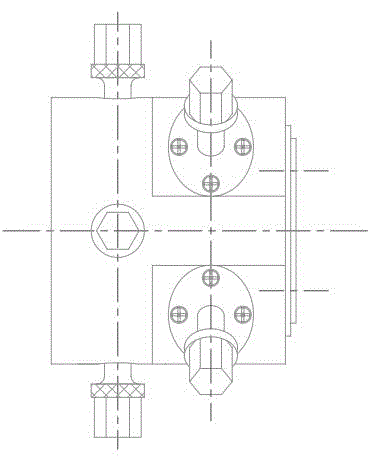

[0019] The clamp for ultra-precision processing with universal adjustment function and self-locking function in this embodiment, the front view is as follows figure 1 shown. The fixture includes a rotating dimension flange 1, a plane dimension adjusting seat 2 that cooperates with the rotating dimension flange 1 through a sub-micron grinding spherical surface at the outer end of the rotating dimension flange 1, and is positioned along the direction of the symmetry axis with the plane dimension adjusting seat 2 1. The housing 3 that moves in the plane of the vertical axis of symmetry, four symmetrically distributed rotating adjustment screw rods 4 pass through the through holes on the housing 3, and are connected with the plane dimension adjustment seat 2 through grinding thread and pass through the plane dimension adjustment seat 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com